Portable welding seam grinding self-walking device for improving fatigue prevention performance

A portable, grinding technology, used in automatic grinding control devices, machine tools suitable for grinding workpiece edges, grinding racks, etc. It can improve the fatigue prevention performance, precisely control the grinding depth, and improve the geometric quality of the weld.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

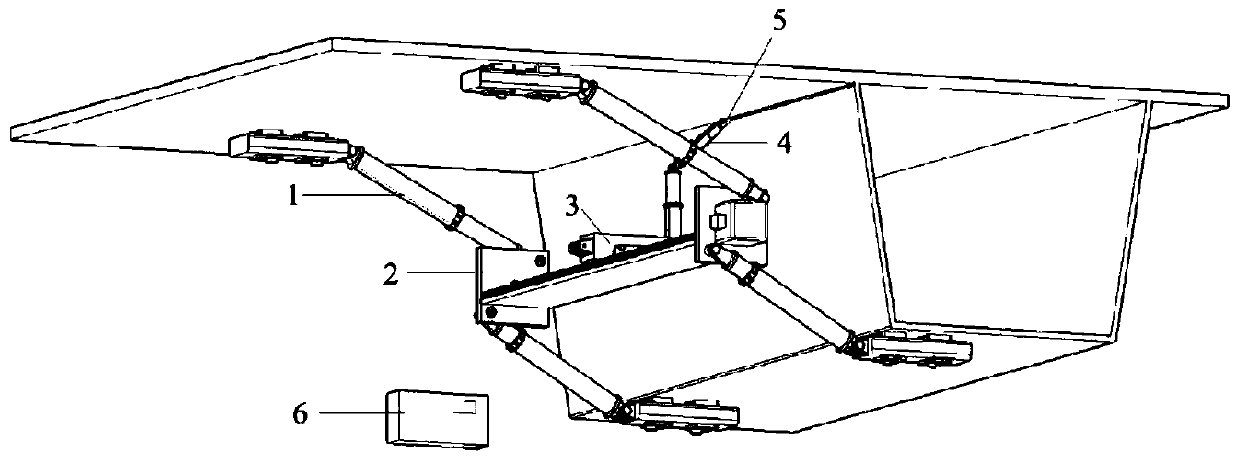

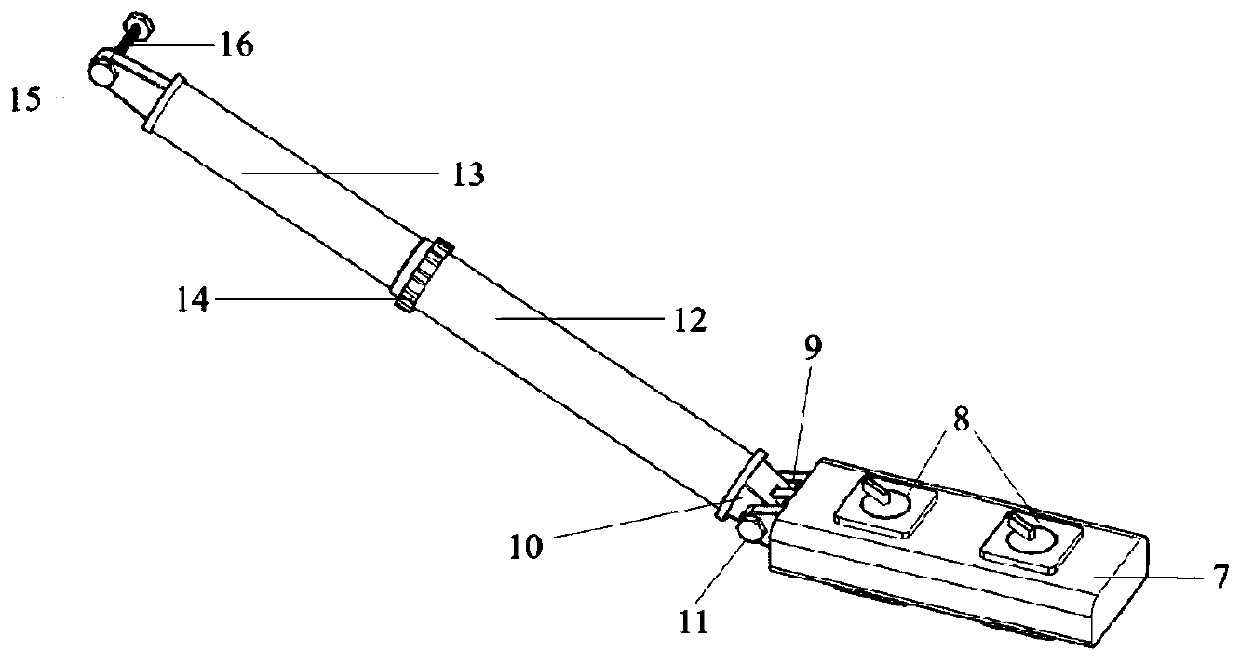

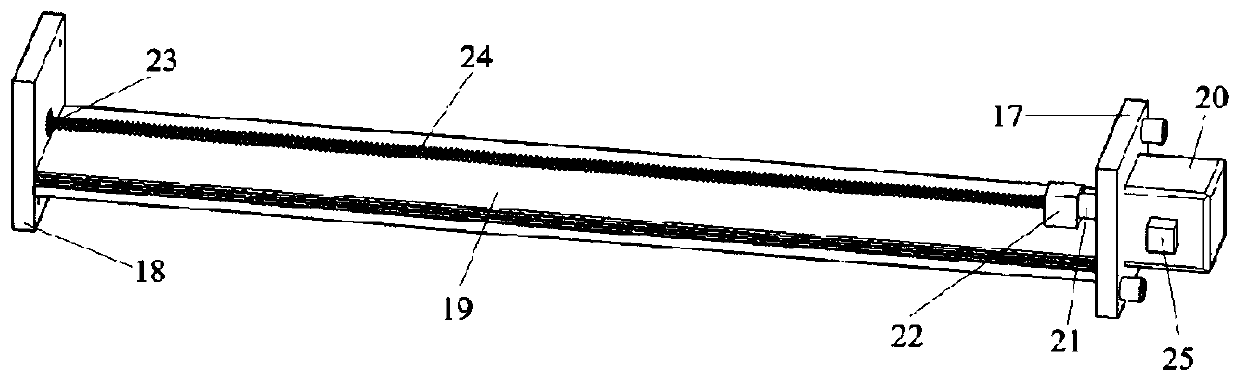

[0039] Such as Figure 1-12 As shown, 1-fixing device, 2-driving device, 3-moving device, 4-depth control rod, 5-grinding system, 6-PLC control system, 7-base, 8-magnetic parts, 9-first rotation Support, 10-the second rotating support, 11-the first bolt, 12-the first telescopic outer rod, 13-the first telescopic inner rod, 14-the first ring locking buckle, 15-the third rotating support, 16-the second bolt, 17 the first baffle, 18 the second baffle, 19-slide rail, 20-the first motor, 21-coupling, 22-fixed base, 23-support base, 24-screw, 25-first data interface, 27-slider, 28-fifth rotating support, 29-roller, 31-sixth rotating support, 32-third bolt, 33-second telescopic outer rod, 34-second Telescopic inner rod, 35-second ring locking buckle, 37-seventh rotating support, 38-fourth bolt, 39-eighth rotating support, 40-dial, 41-gear,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap