Combined hole-pattern damper seal with flanged damping holes

A combined and damping technology, applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve the problems of poor turbulence effect of traditional hole-type damping seals, cumbersome production of honeycomb damping seals, and high cost, and achieve maintenance and replacement. It is simple and convenient to seal the stator surface, reducing the cost and workload, and improving the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The implementation of the present invention will be further detailed below in conjunction with the drawings:

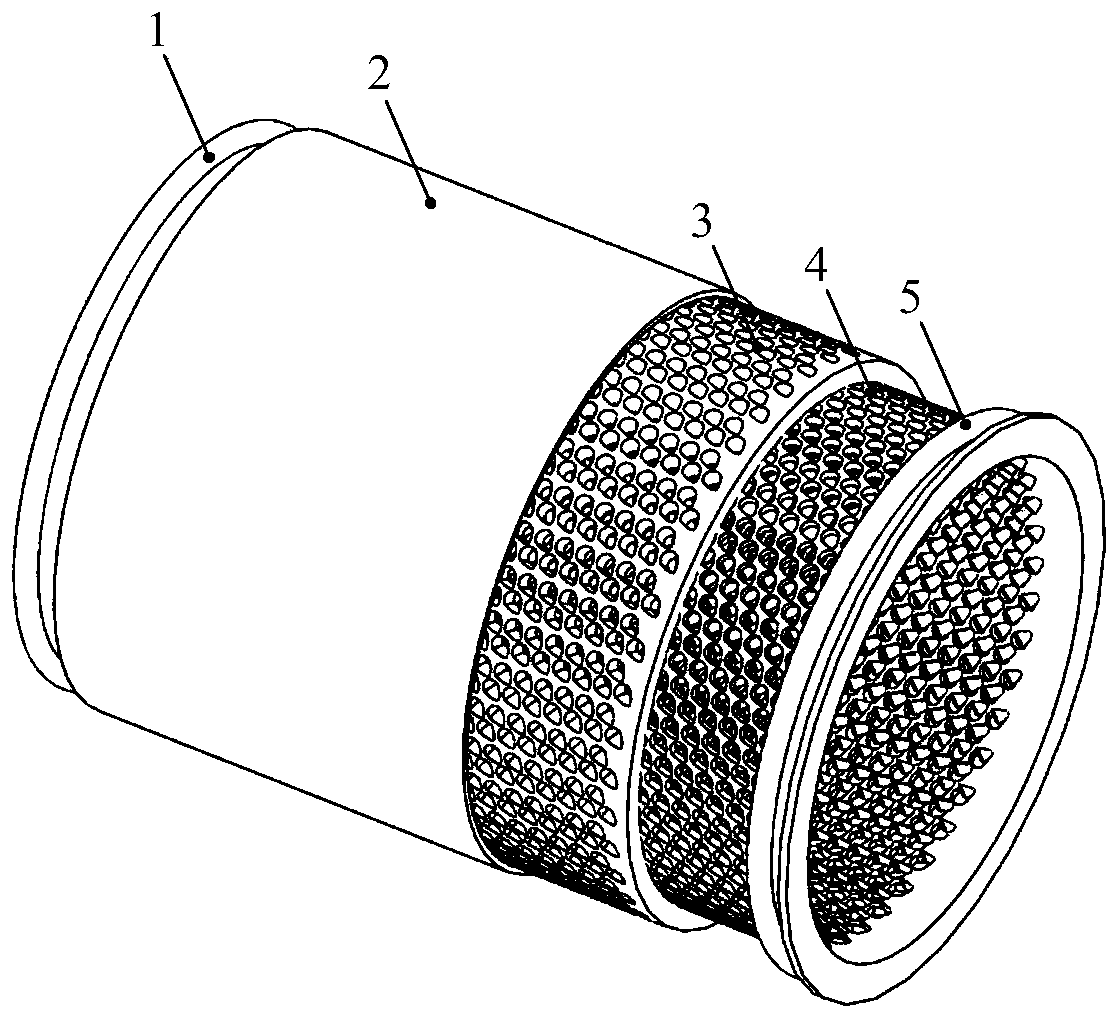

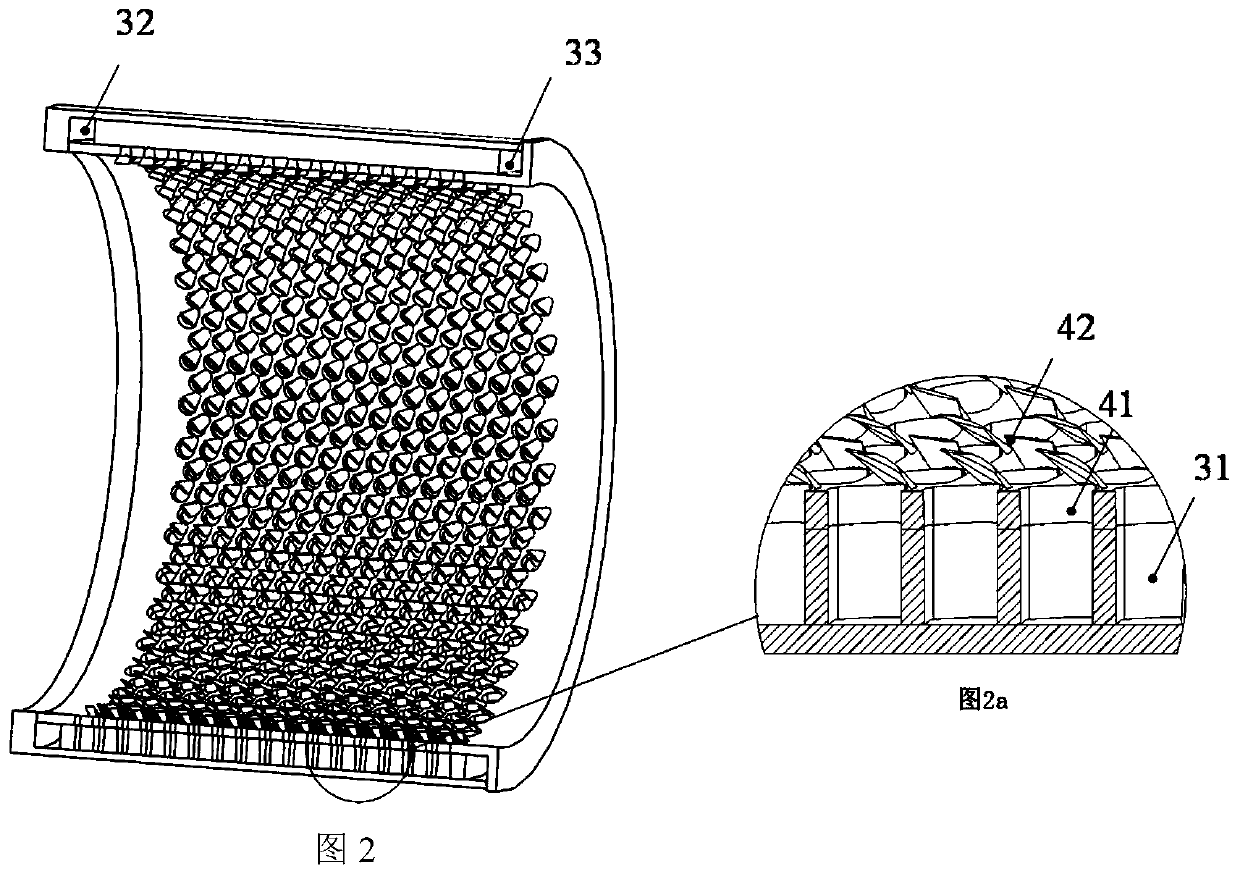

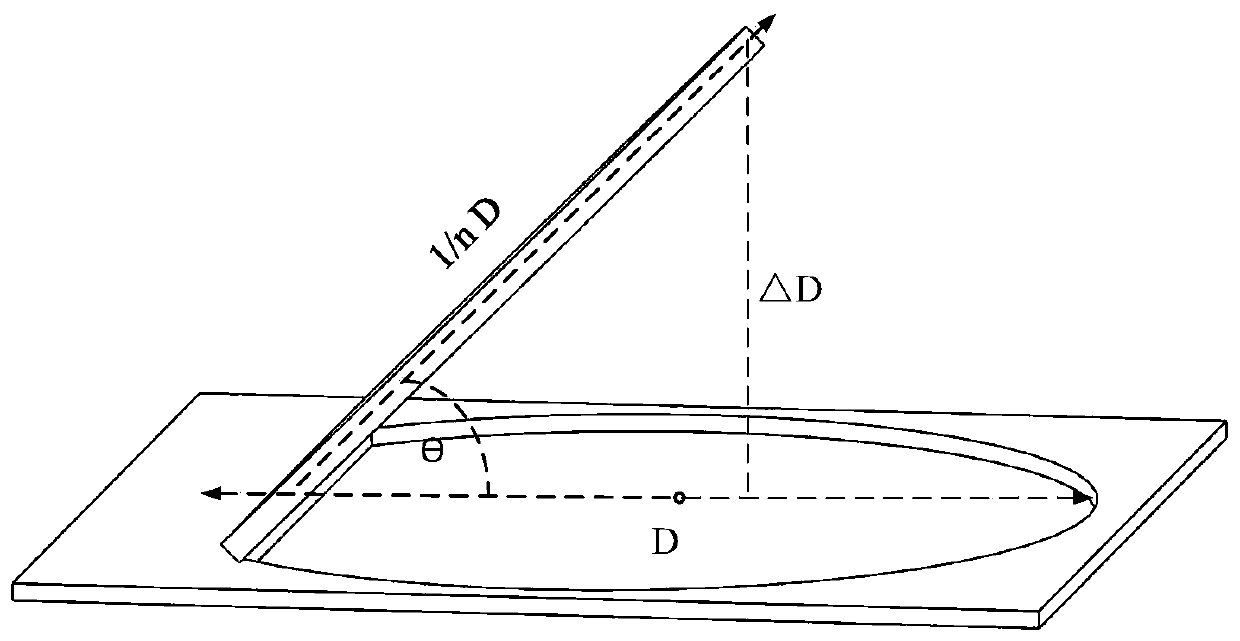

[0025] See figure 1 , 2 And 3, a combined orifice damping seal with flanged damping orifices, including a three-layer combined sealing sleeve and an interlayer auxiliary elastomer sealing ring. The three-layer combined sealing sleeve includes an inner lining sealing cylinder 4, an intermediate sealing cylinder 3, and an outer sealing cylinder 2. The circumferential surface of the lining sealing cylinder is machined with evenly distributed belt flanges. 42 of the damping hole 41, one end of the lined sealing cylinder is processed outwards into a right-angle hemming, the middle sealing cylinder is a straight cylinder and the cylinder circumference is processed with evenly distributed flow grooves 31. The diameter of the damping hole 41 is not greater than the diameter of the flow groove 31 and the center lines of the two are superimposed, and the outer sealing cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com