A Vibration Fatigue Test Device for Fan Blades with Protruding Shoulder of Engine

A technology of vibration fatigue and test equipment, which is applied in vibration testing, measuring equipment, testing of machine/structural components, etc. It can solve the problems of destroying the blade structure and the inability to accurately simulate the boundary conditions of the blade, etc., and achieves a wide range of applications and is easy to fatigue The effect of testing and facilitating the adjustment of preload force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in further detail below in conjunction with accompanying drawing:

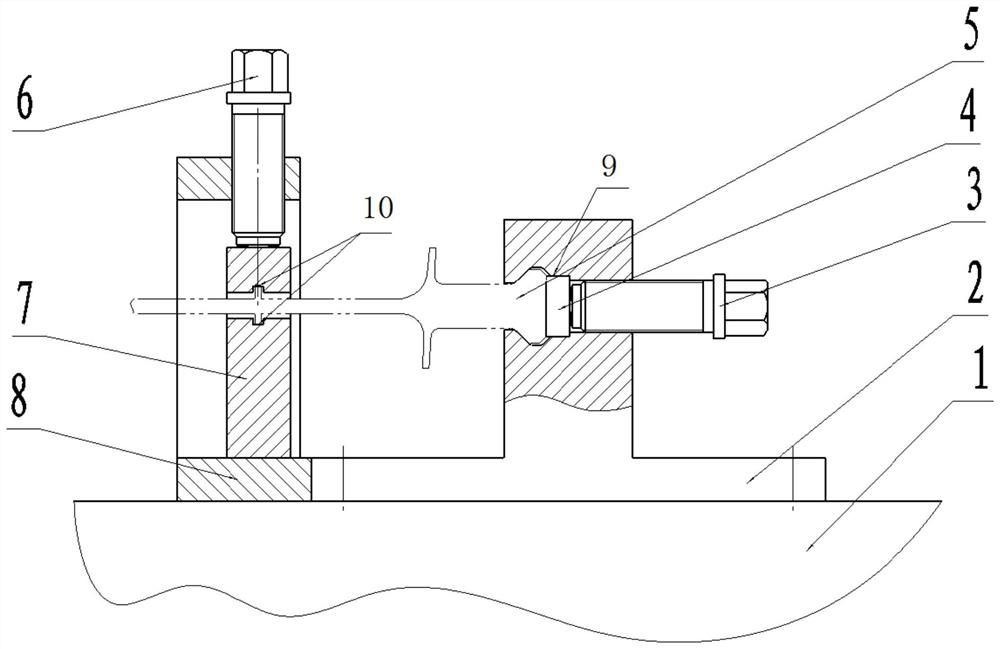

[0027] Such as figure 1 As shown, a vibration fatigue test device for fan blades with shoulders of an engine includes a tenon positioning block 2, a shoulder clamping block 7 and a shoulder fixing frame 8, and the tenon positioning block 2 and shoulder fixing frame 8 are fixed on a vibration table 1 superior;

[0028] The tenon positioning block 2 is provided with a tenon ejector groove and a tenon groove 9, and the tenon ejector groove is provided with a tenon ejector 3, and the tenon ejector groove communicates with the tenon groove 9, and the section of the tenon groove 9 coincides with the blade tenon 5;

[0029] The shoulder clamping block 7 is provided with a shoulder groove 10 for supporting the blade shoulder. The shoulder groove 10 is a through-hole structure along the axial direction of the blade shoulder, and the shoulder groove 10 is an open structure alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com