Testing device and testing method for quickly determining self-polishing rate of resin

A technology of rapid measurement and testing device, applied in the direction of removing certain components, such as weighing, etc., can solve the problems of long test cycle and other problems, and achieve the effect of small error, time saving and efficiency improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] Step 1. Coat resin on the test sample board and dry it at room temperature for 10 days. The coating area S is 19cm. 2 , Measuring weight W 0 Is 6.224g;

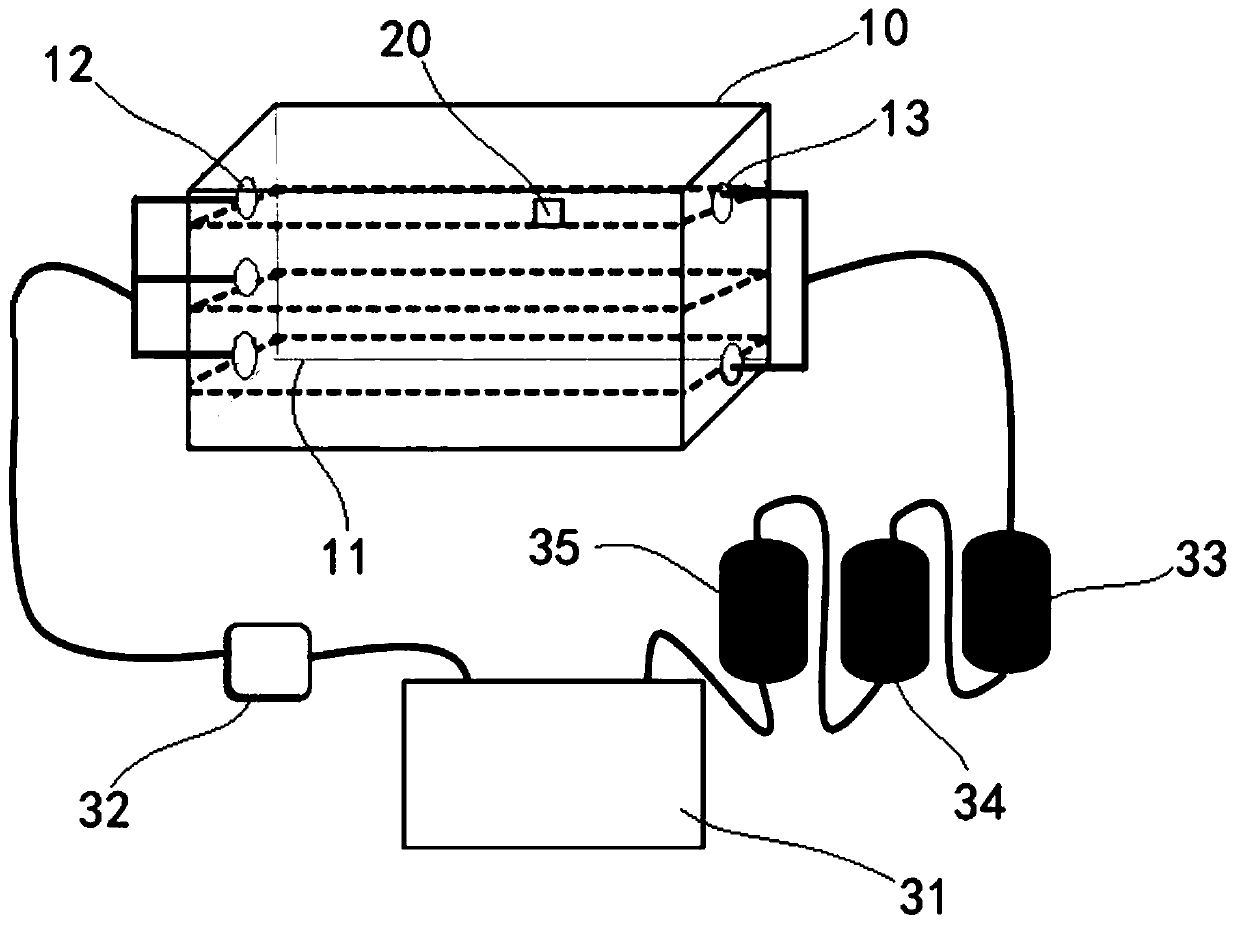

[0047] Step 2: Put the test sample after the coating resin is dried into the water storage tank, turn on the test device, and soak;

[0048] Step 3. Take out after soaking for a period of time, calculate the soaking time t, and weigh the weight of the test sample after soaking, W n , N is the test period;

[0049] Step 4. Put the test sample into the water storage tank again for soaking, repeat the steps three times;

[0050] Step five, use the formula polishing rate v = (W n-1 -W n ) / (t×S), calculate the polishing rate value, and then average.

[0051] A total of 8 cycles were tested, and the test data for each cycle is shown in Table 1:

[0052] Table 1

[0053] W n (g)

[0054] Since the data of the first cycle may be caused by the incomplete volatilization of the solvent, the value is excluded, so the average value is calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com