Pit-diameter-adjustable pit digging assembly facilitating nursery stock planting

An adjustable, pit-diameter technology, applied in planting methods, excavation/covering trenches, applications, etc., can solve problems such as high noise, high labor intensity, and poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

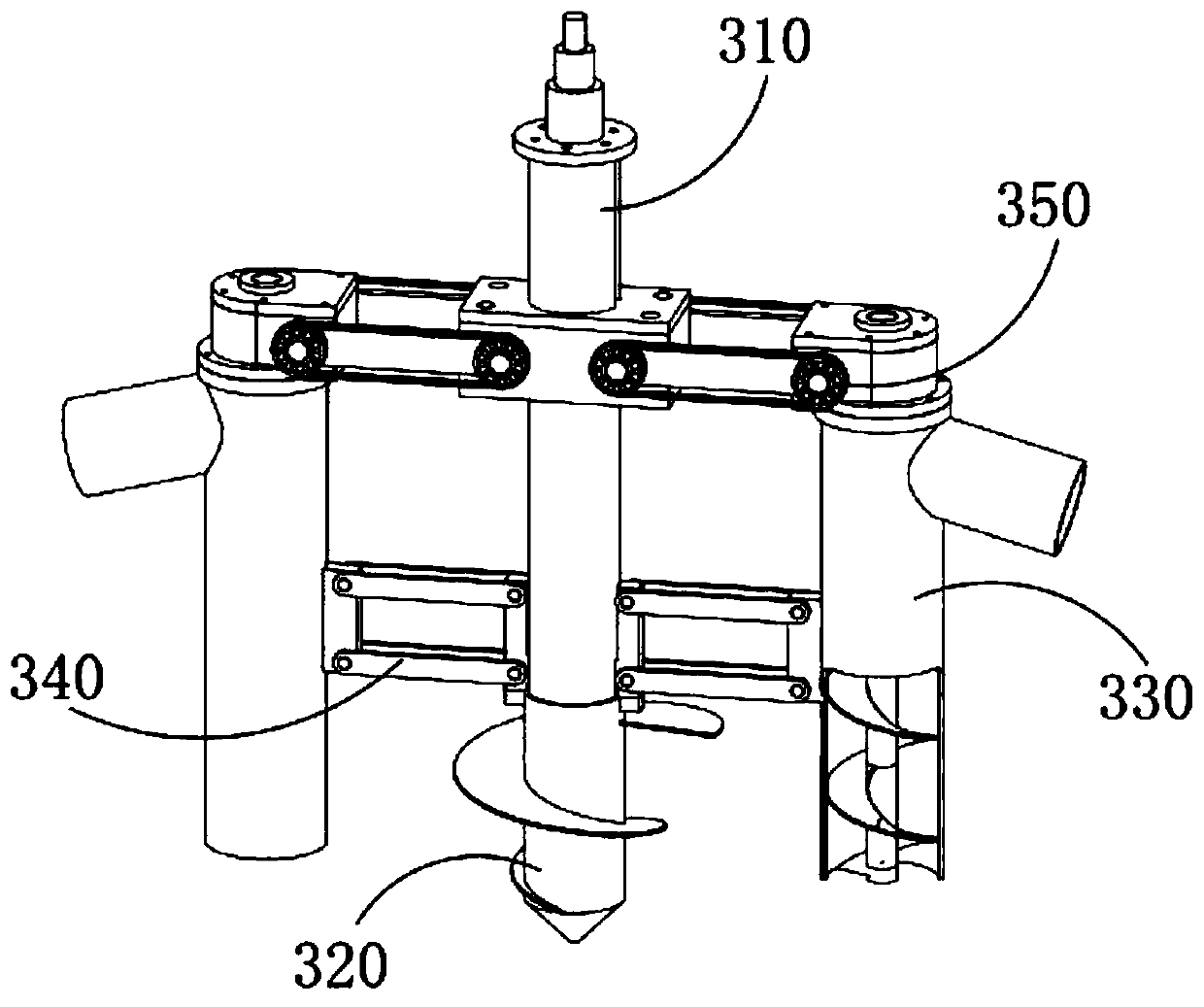

[0060] The advantage of the present invention over the existing digging mechanical equipment is that the diameter of the pit dug by the digging equipment can be adjusted and changed according to actual requirements, and the adjustment process is fully automatic, and the operator only needs to turn off the engine after the pit diameter meets the requirements , and then manually disconnect the closing switch. The whole process is simple and quick to operate, without the operator's trouble and effort, and is more convenient; And it is finally transported to the excavation barrel together with the outer soil to be discharged, so as to avoid the splash of the soil and the injury to the operator during the digging process.

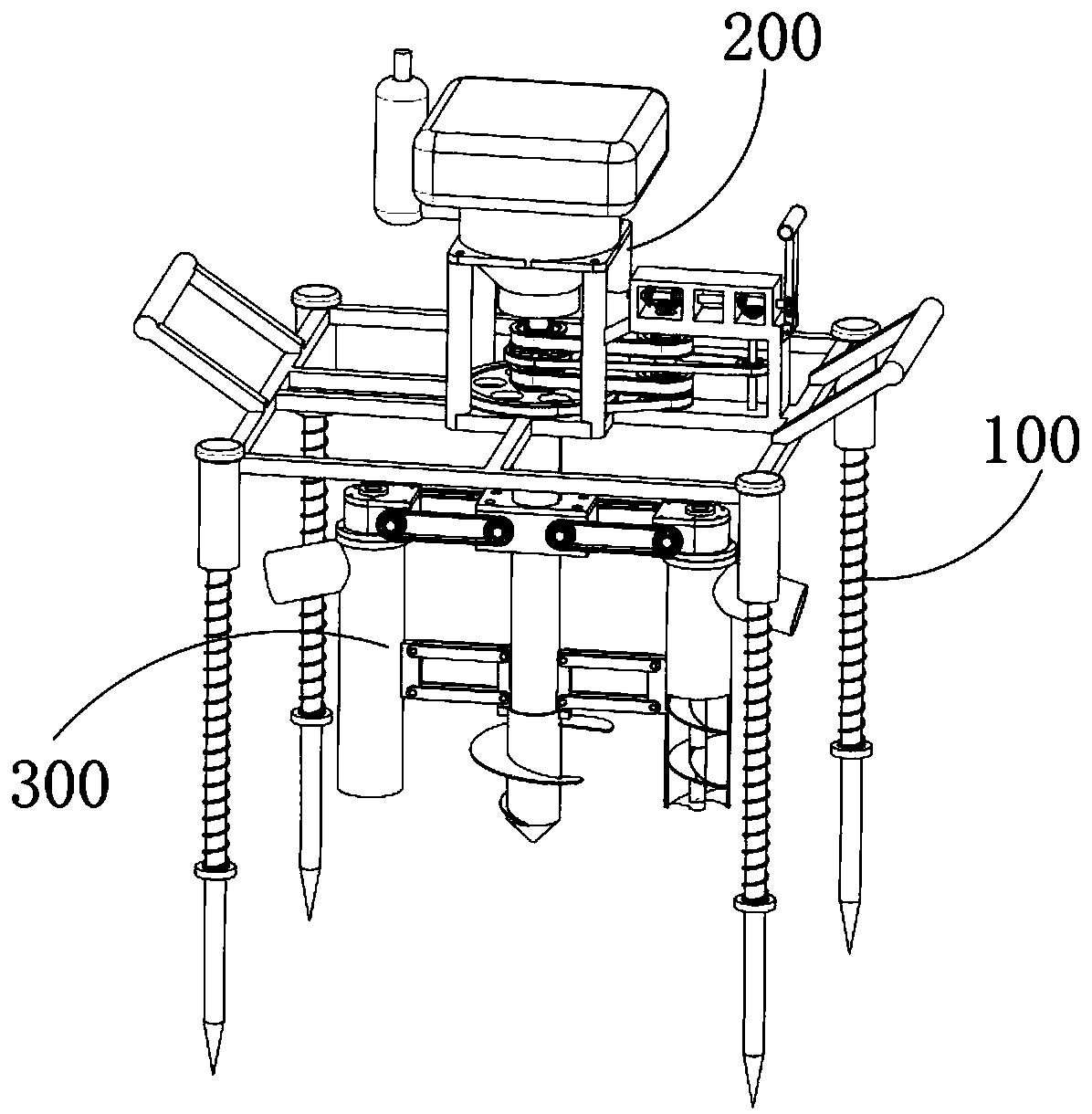

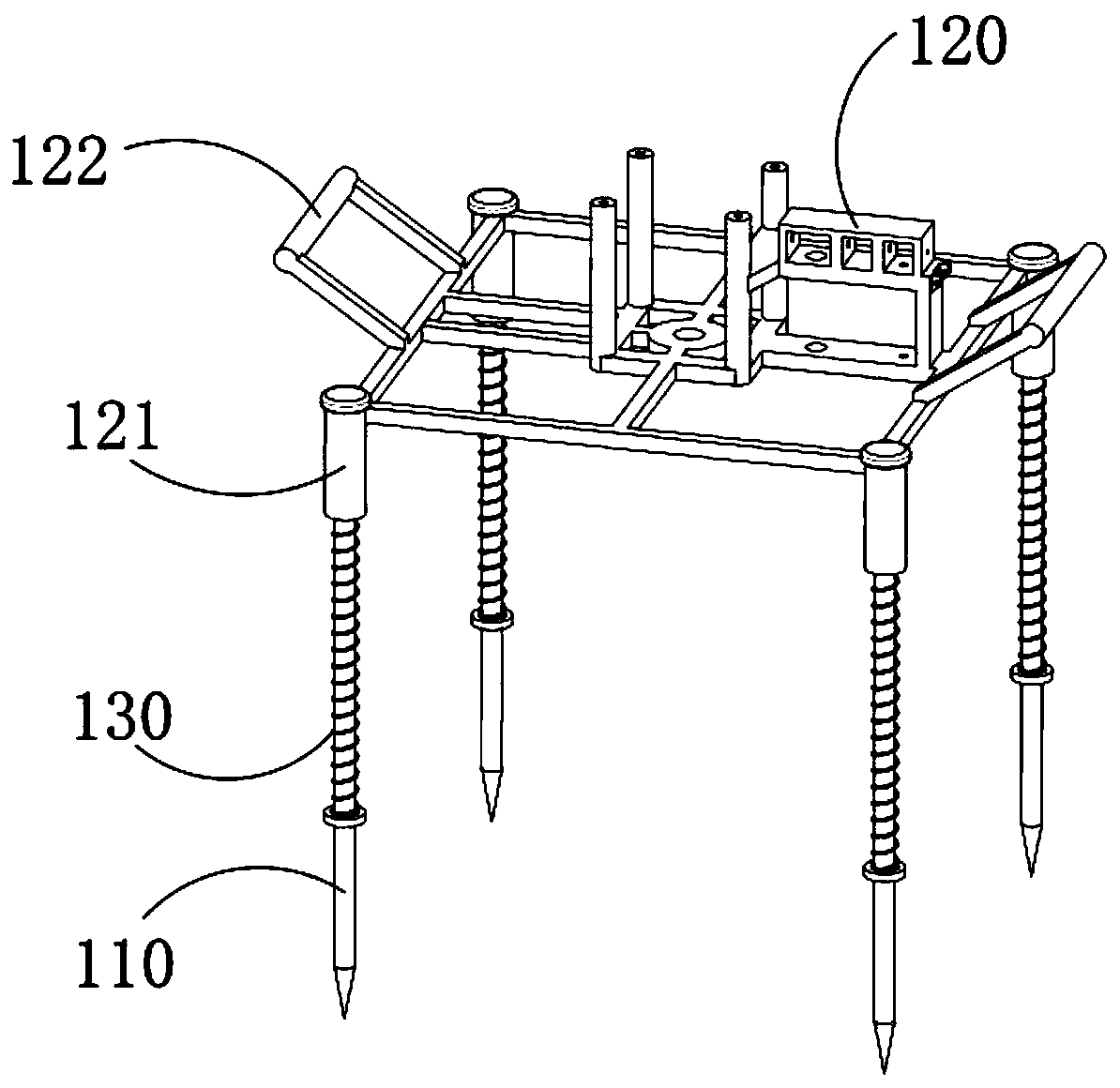

[0061] Self-expanding variable diameter pit digging equipment, which includes a frame body 100, a pit digging device installed on the frame body 100 and used for digging pits with adjustable pit diameter, the pit digging device includes a power mechanism 200, a v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com