Automatic kelp seedling clamping machine

A seedling clamping machine and kelp technology, which is applied in seaweed cultivation, horticulture, botany equipment and methods, etc., can solve the problems of kelp seedlings easy to fall off, heavy labor, high cost, etc., and achieve good effect of clamping seedlings, high operating efficiency, The effect of not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

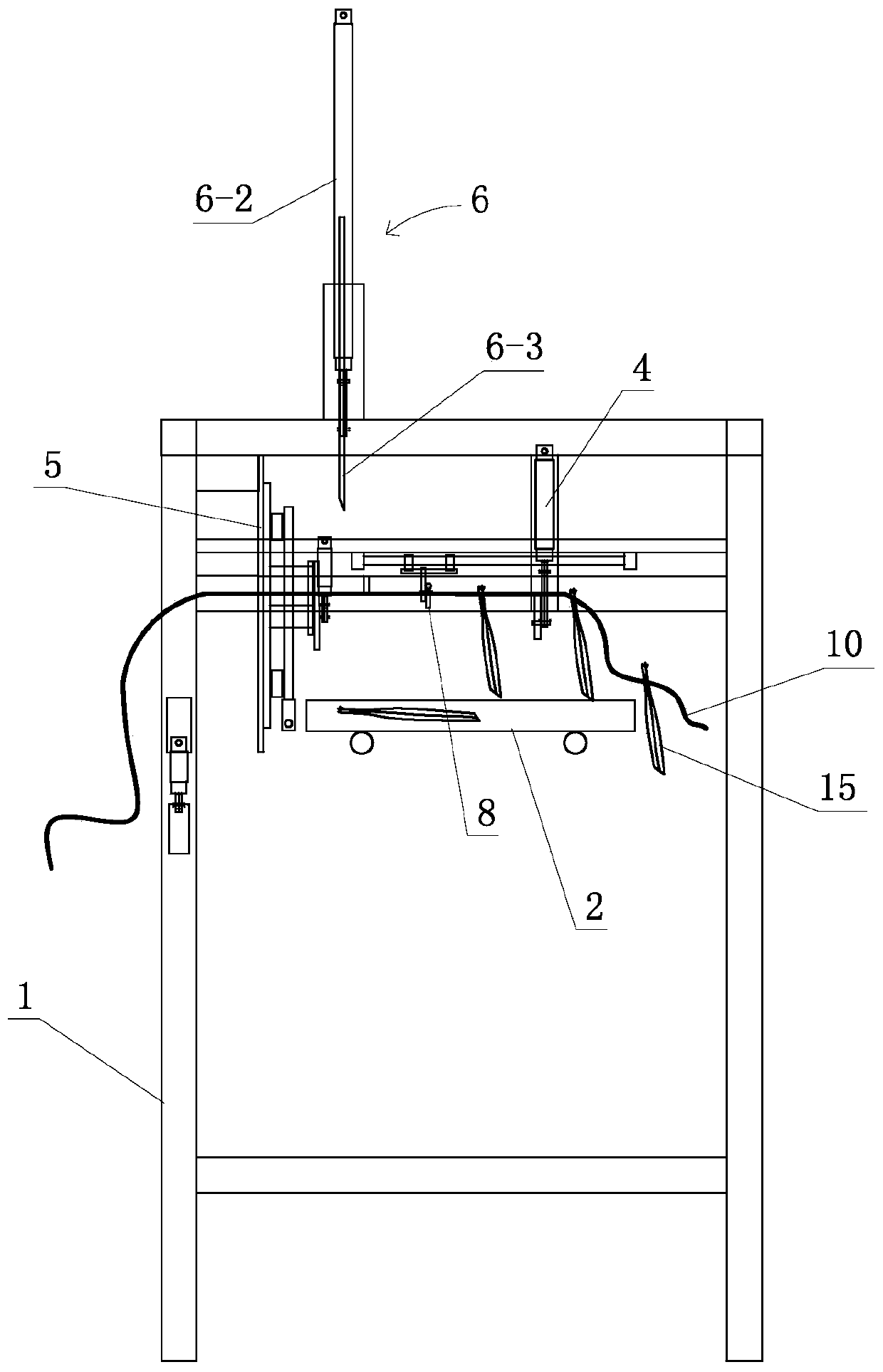

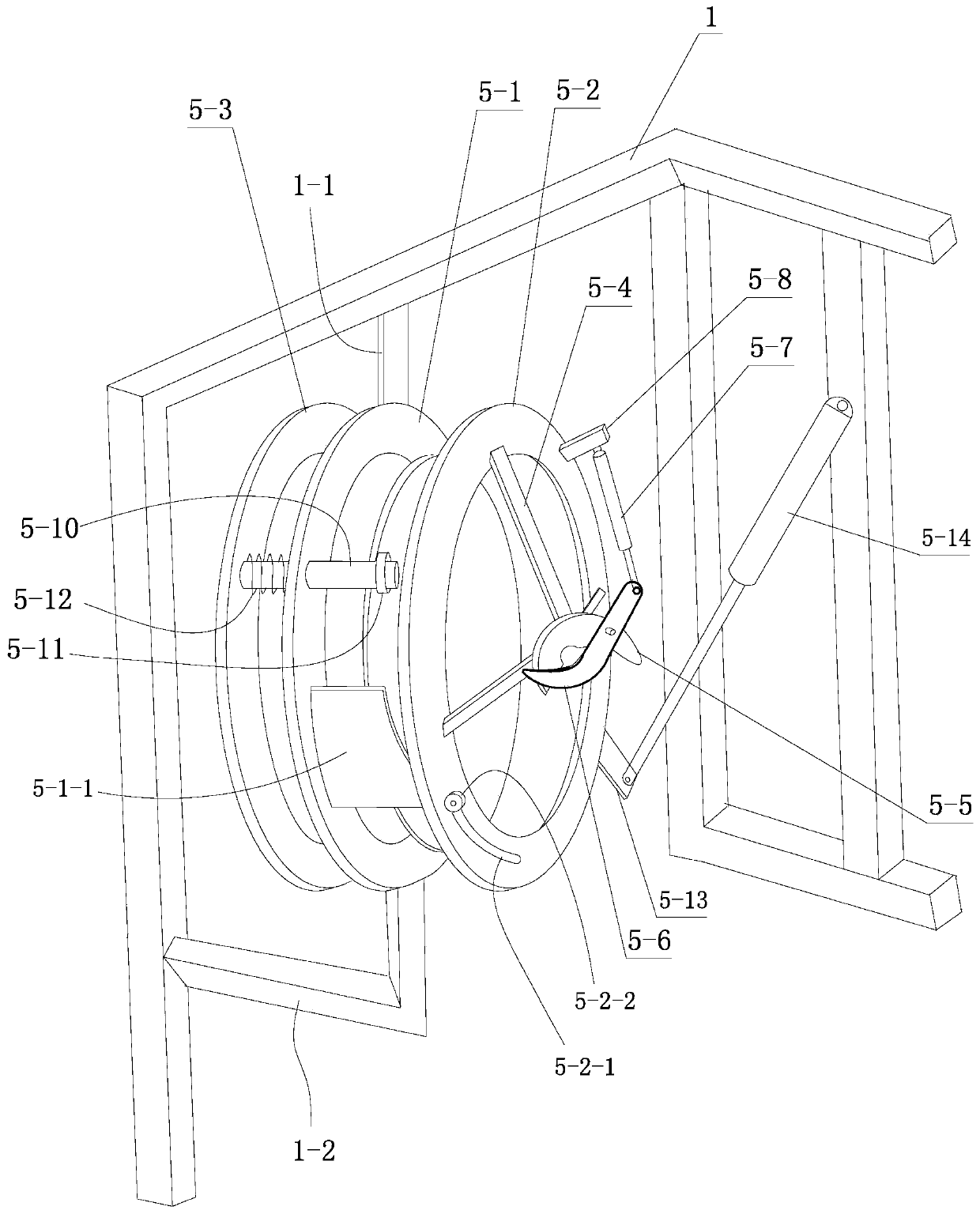

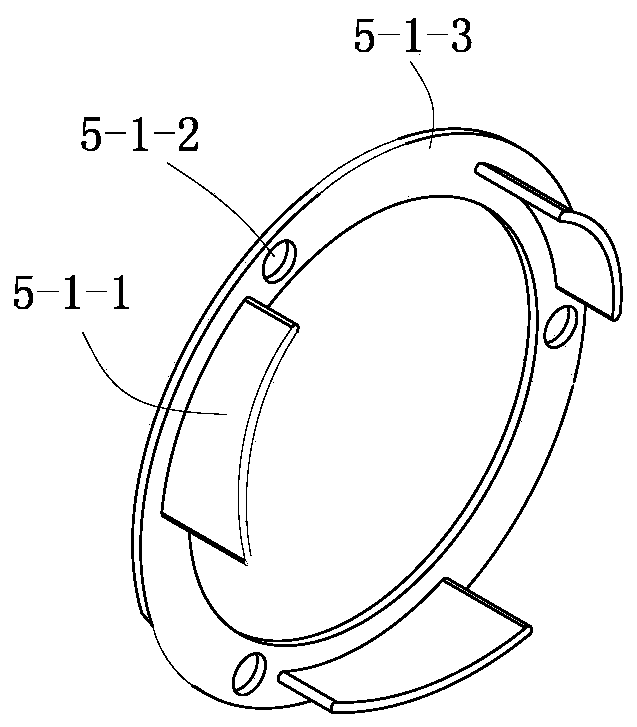

[0039] like Figure 1-4 As shown, the automatic kelp clamping machine includes a support frame 1, a hopper 2, a hopper support 3, a seedling rope fixing mechanism 4, a twisting rope device 5, a seedling suction device 6, a device 7, and a rope support frame 8.

[0040] The material box support 3 is fixedly installed in the middle part of the support frame 1, and the material box 2 is connected with the material box support 3. A translation mechanism such as a slide rail assembly can be installed on the feed box bracket 3, so that the feed bin 2 is connected with the slide rail assembly, thereby realizing the translation of the feed bin 2 to adjust the position of the feed bin 2.

[0041] Seedling suction device 6 comprises seedling suction cylinder support 6-1, seedling suction cylinder 6-2, suction pipe 6-3, and seedling suction cylinder support 6-1 is fixedly installed on the top of support frame 1, and seedling suction cylinder 6-2 is installed on the top of suction On the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com