Draining device for preparing pickled Chinese cabbages

A technology for draining and sauerkraut, which is applied in the field of draining devices for preparing sauerkraut, can solve the problems of affecting work efficiency and long time, and achieve the effects of improving work efficiency, drying speed and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

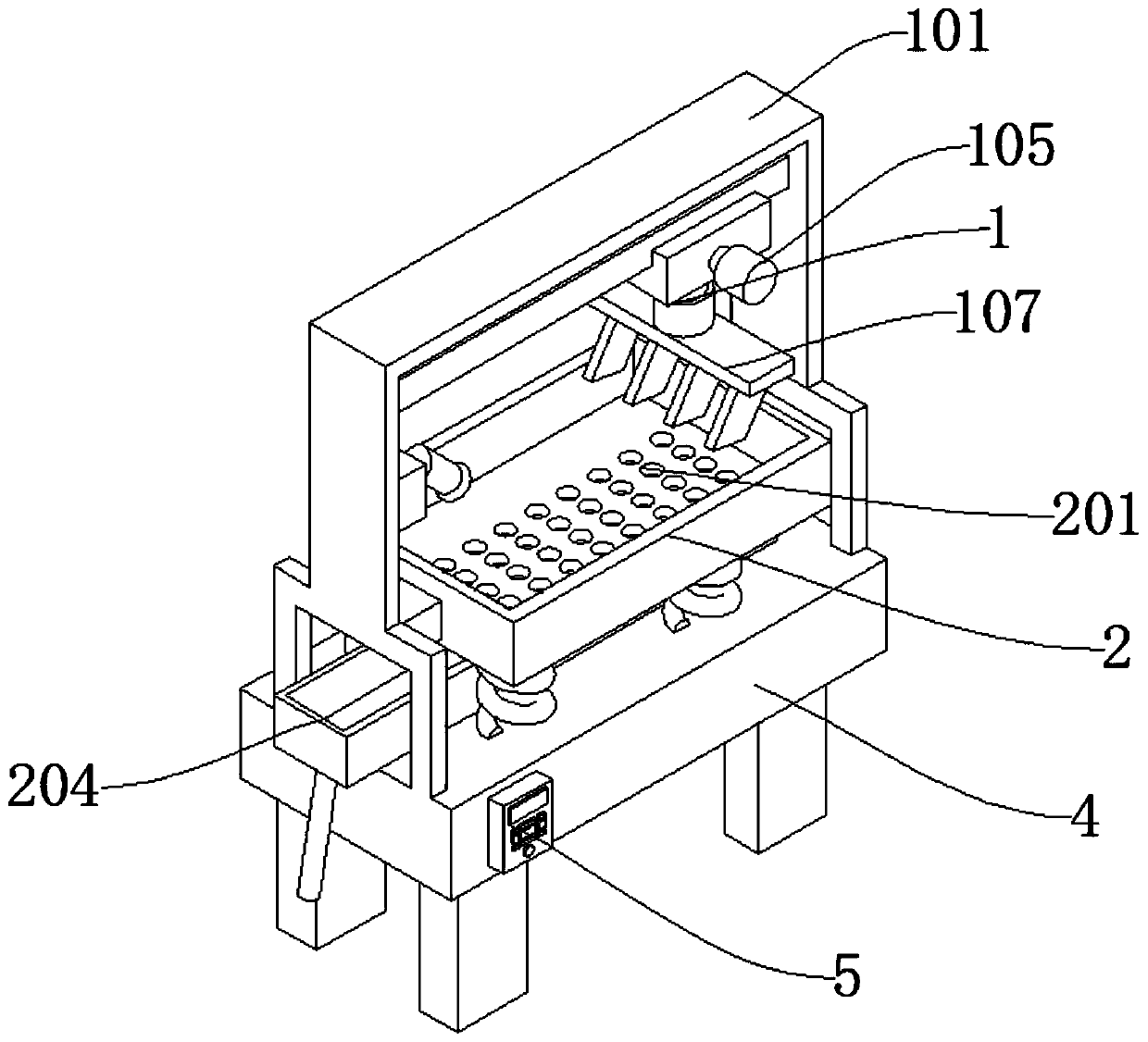

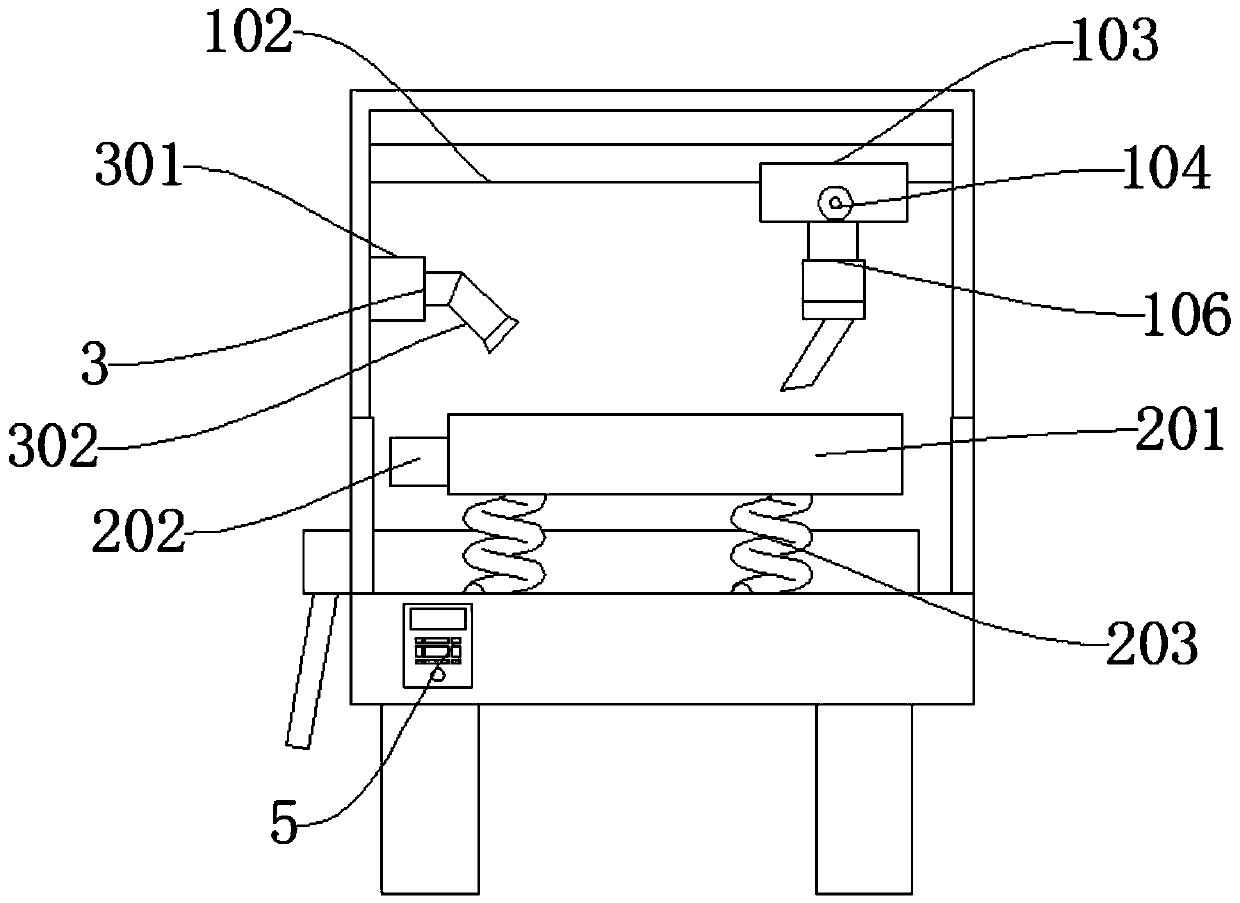

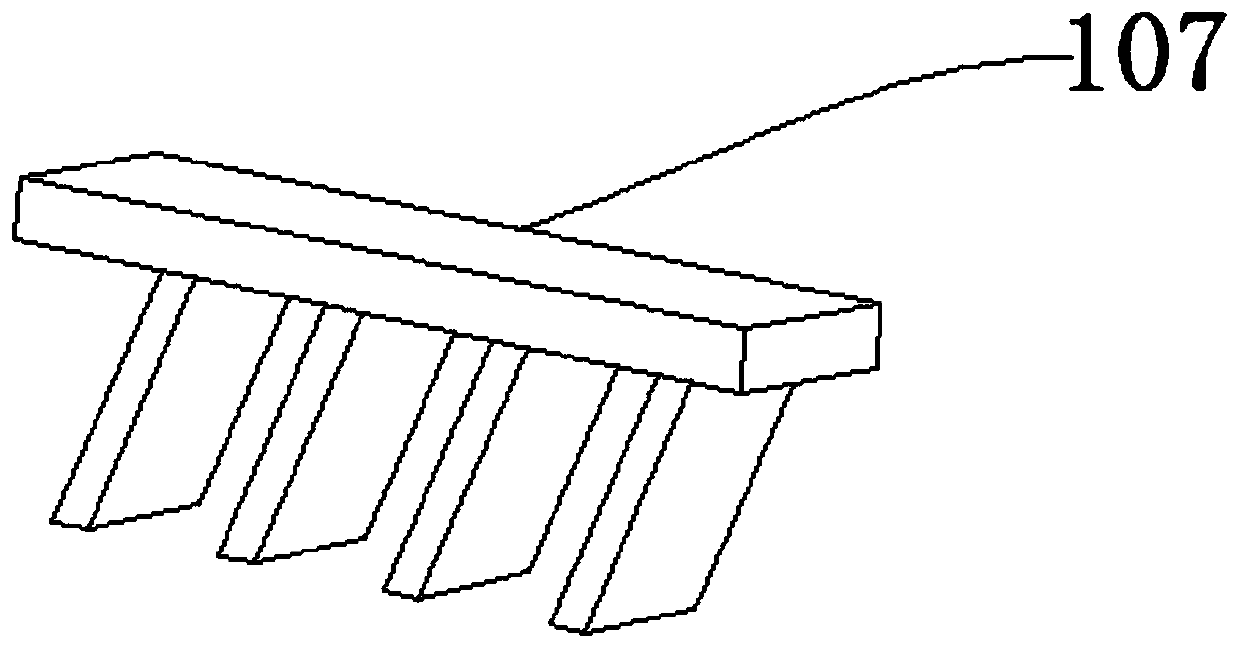

[0026] Such as figure 1 , figure 2 , image 3 , Figure 5 As shown, the present invention provides a technical solution: a draining device for preparing sauerkraut, comprising a drying mechanism 3, a workbench 4, a controller 5, a vibrating mechanism 2 is arranged above the workbench 4, and a vibrating mechanism 2 is arranged above the vibrating mechanism 2. Material turning mechanism 1, material turning mechanism 1 comprises support 101, slide rail 102, slide table 103, and slide rail 102 is installed on the inside of support 101, and slide rail 102 is provided with slide table 103, and slide table 103 interior is equipped with roller 104, and roller 104 is used for transmission, and motor 105 is installed in slide table 103 front portion, and electric telescopic column 106 is installed below slide table 103, and material turning frame 107 is installed below electric telescopic column 106, and material turning frame 107 is in order to turn material, motor 105, The electri...

Embodiment 2

[0030] Such as Figure 4 , Figure 6 As shown, the difference between Embodiment 2 and Embodiment 1 is that the drying mechanism 3 includes a mount 303 and a heat lamp 304 , the heat lamp 304 is mounted on the mount 303 , and the heat lamp 304 is electrically connected to the controller 5 .

[0031] The hot air blower 301 blows hot air to the raw material through the air outlet pipe 302, and replaces it with a heat energy lamp 304 to irradiate the raw material to accelerate the drying of the raw material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com