Patents

Literature

41results about How to "Improve draining efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

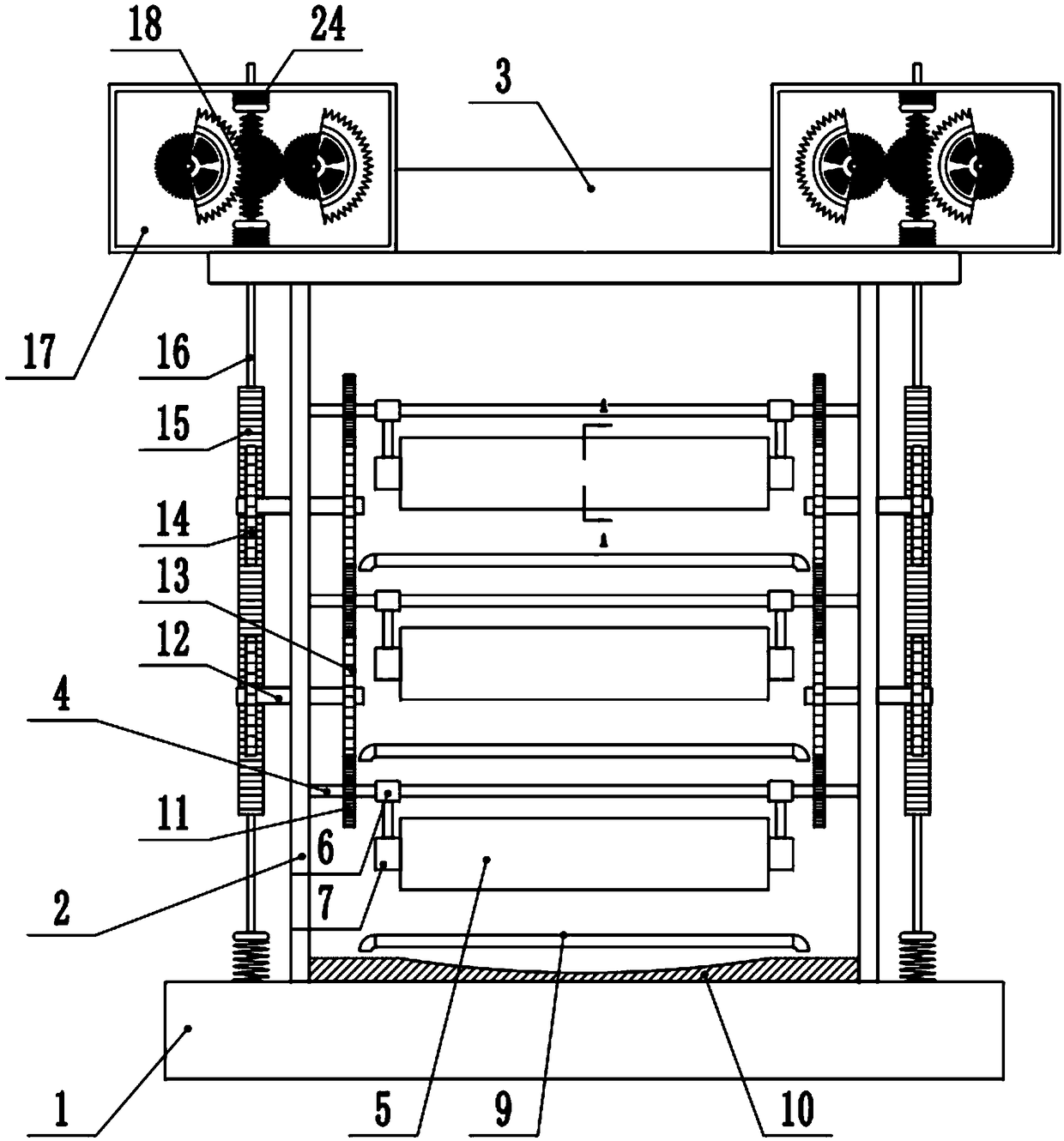

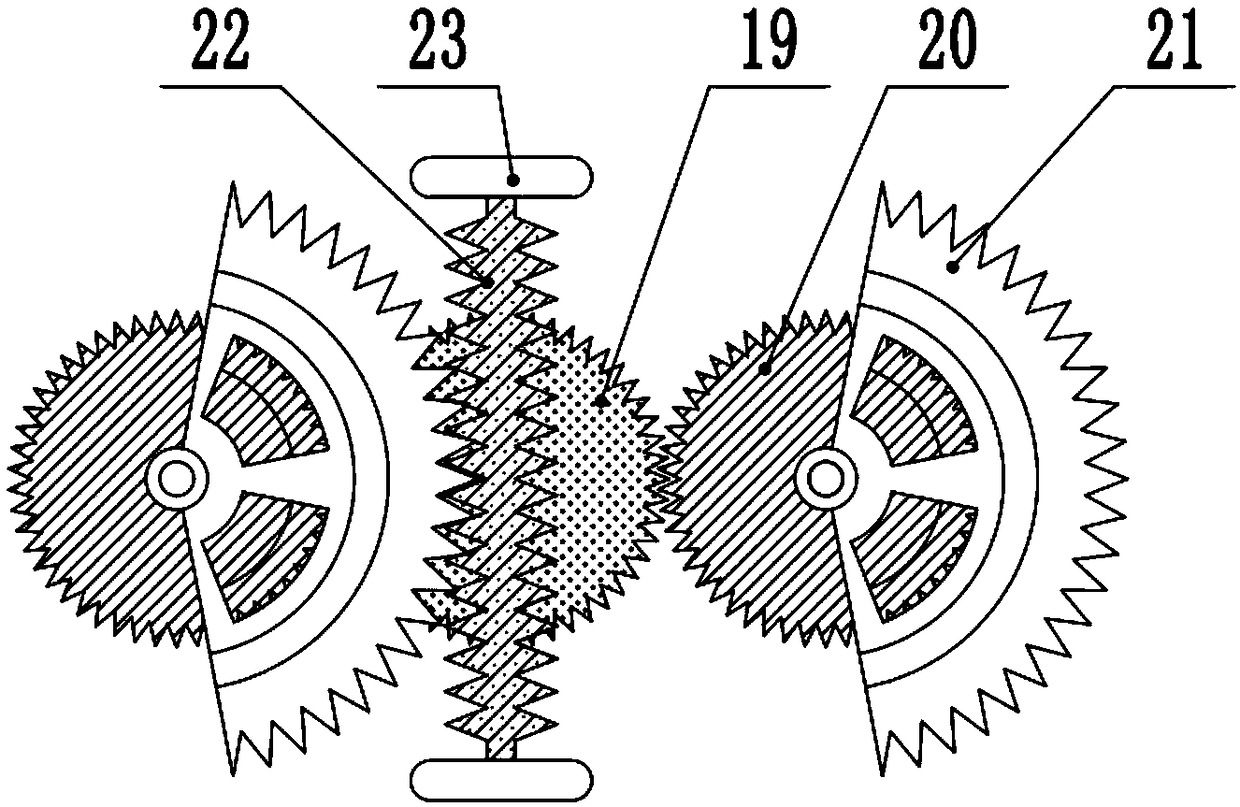

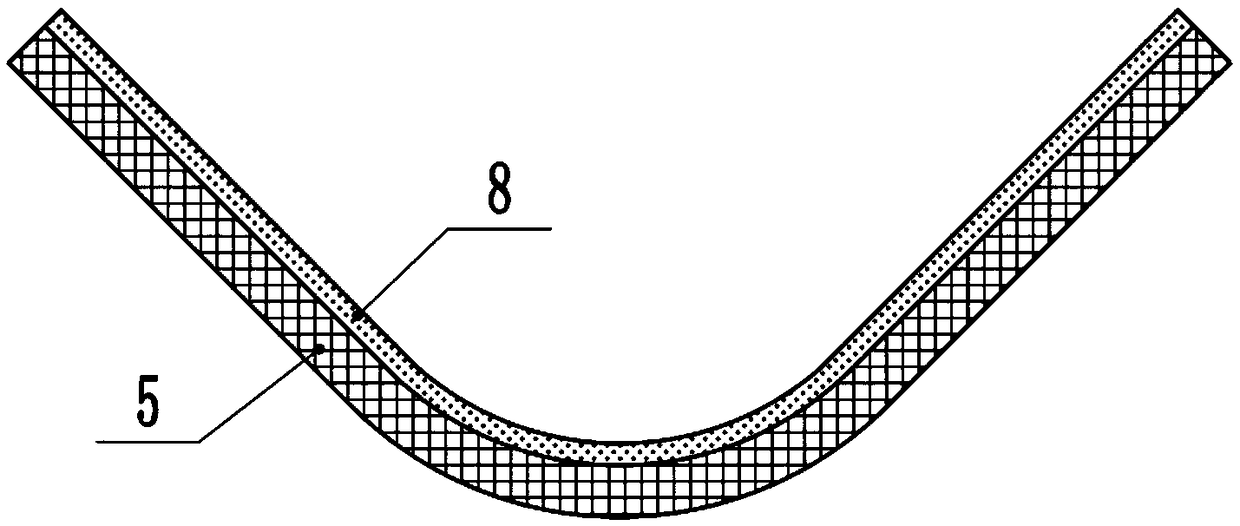

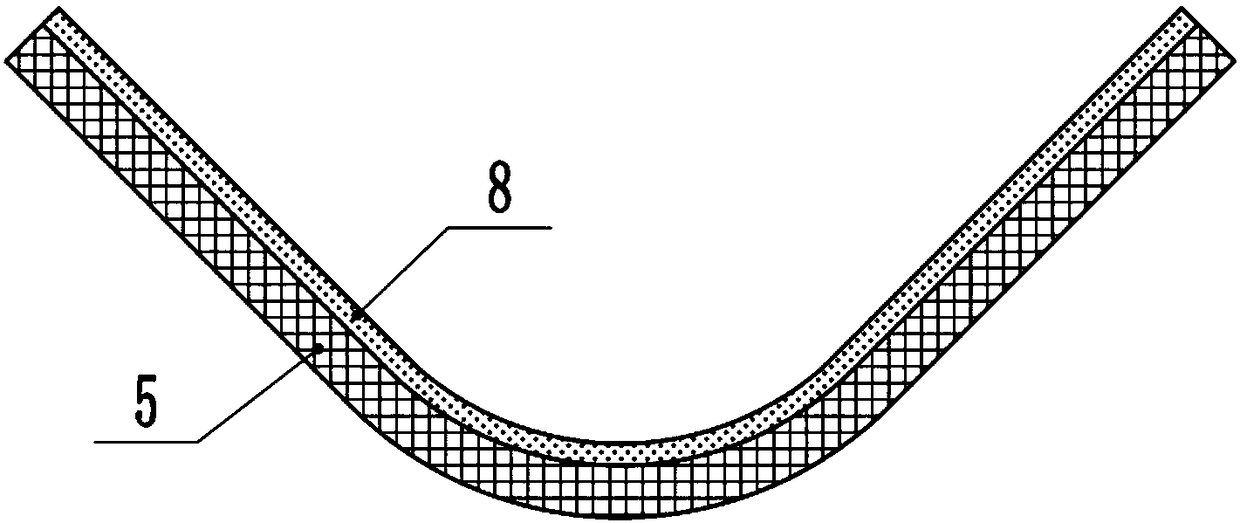

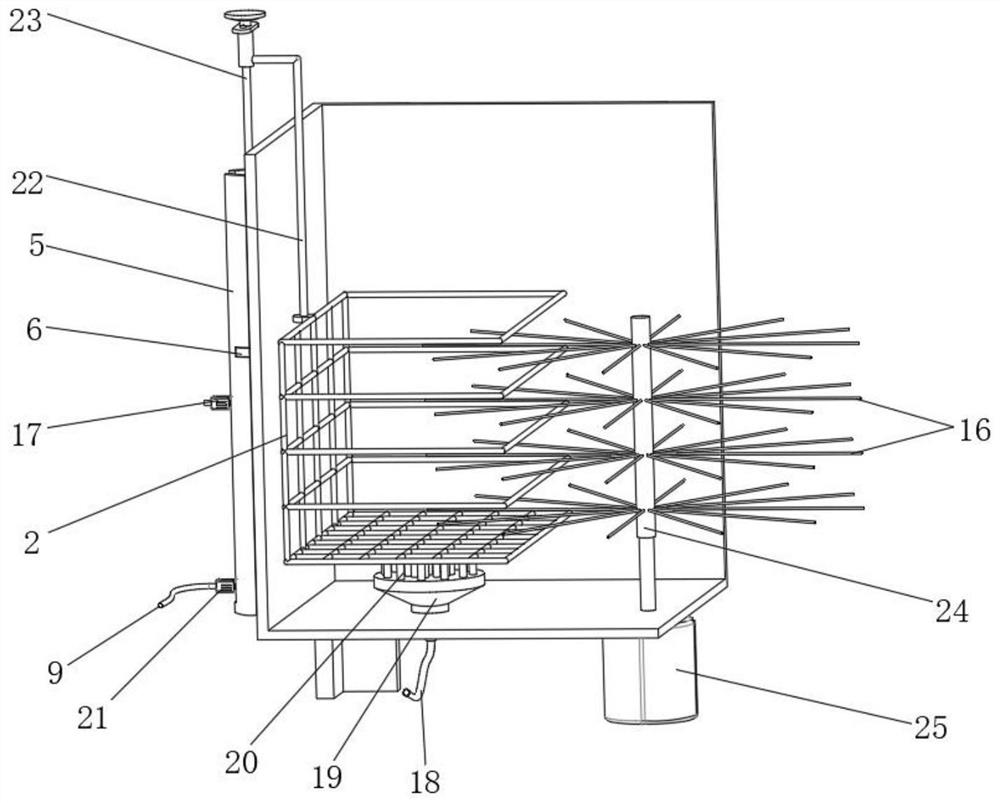

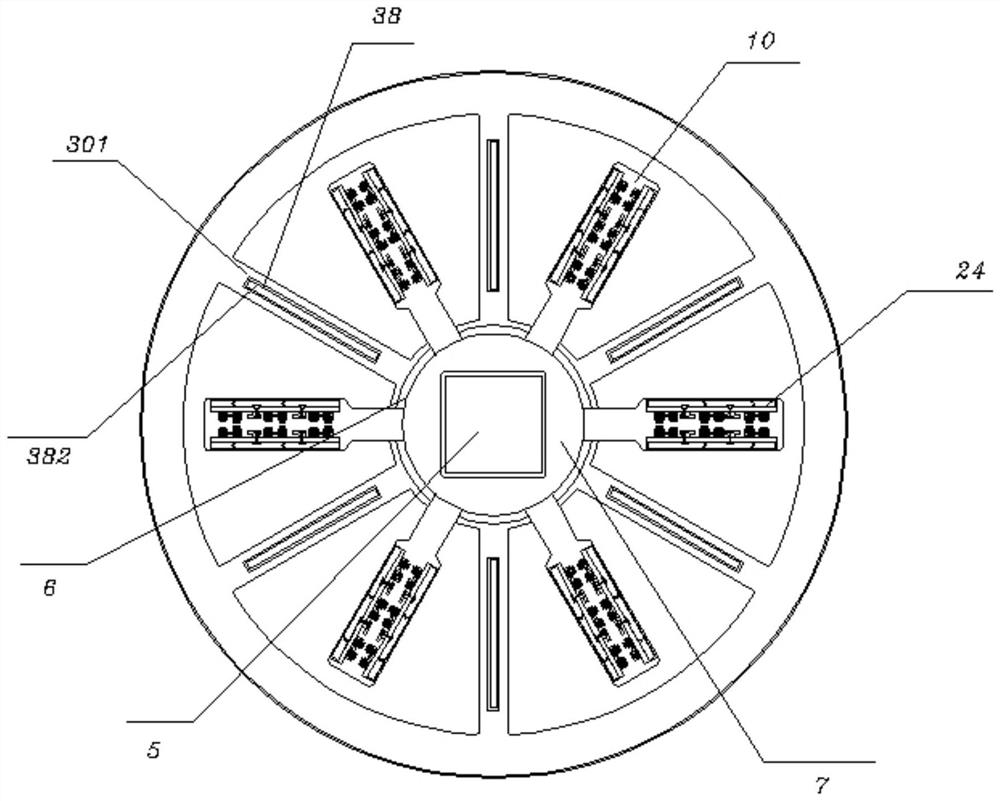

Gear assembly driving type swing type seed draining device

InactiveCN108709385ASimple structureImprove efficiencySeed and root treatmentDrying solid materials without heatDrain efficiencyMechanical engineering

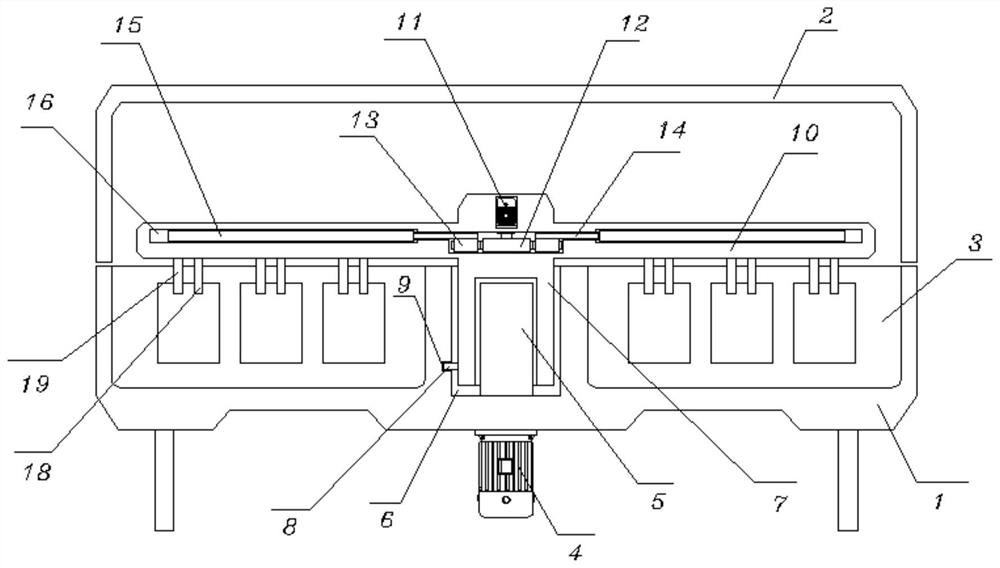

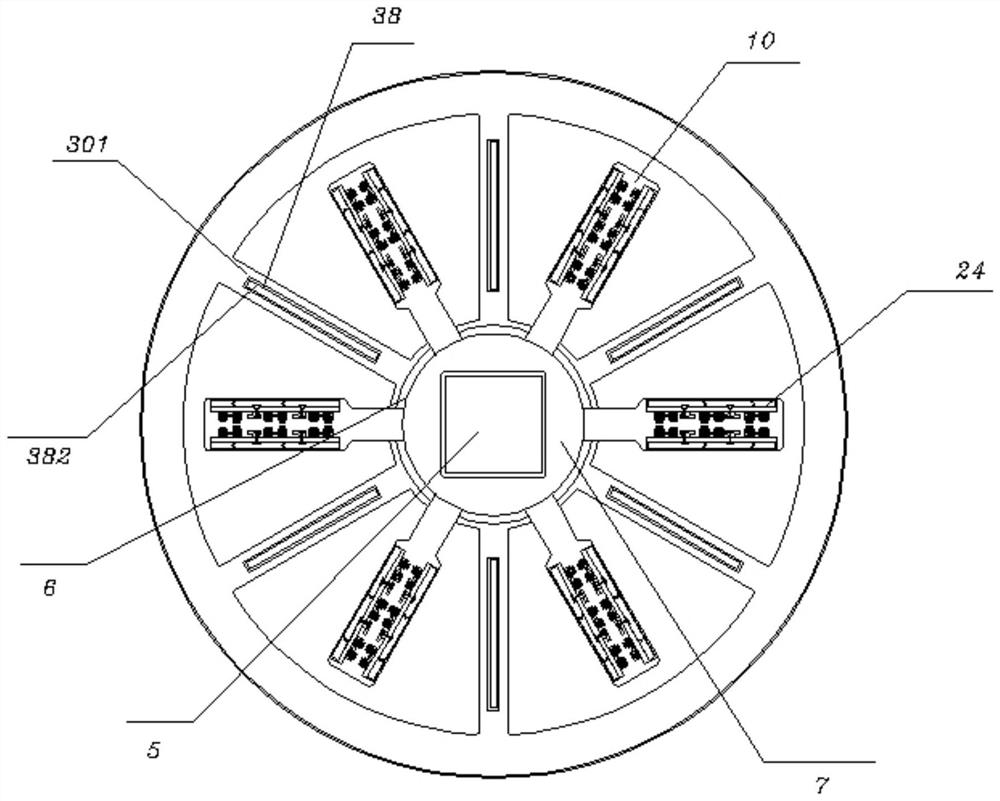

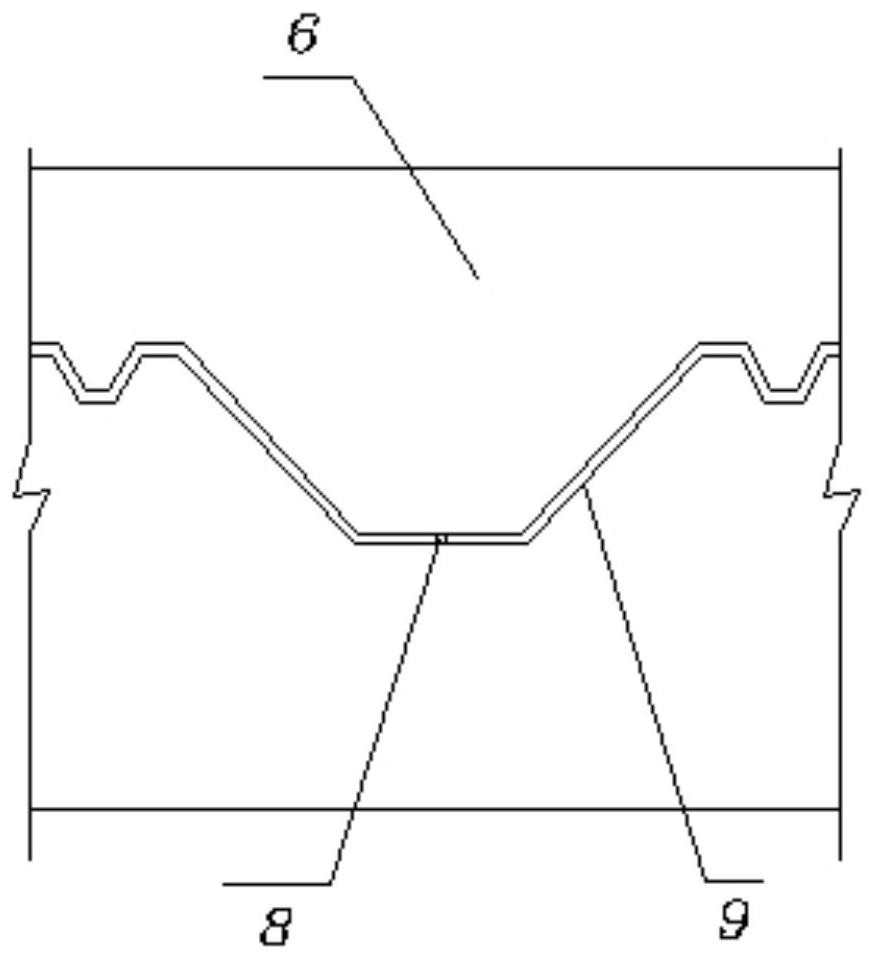

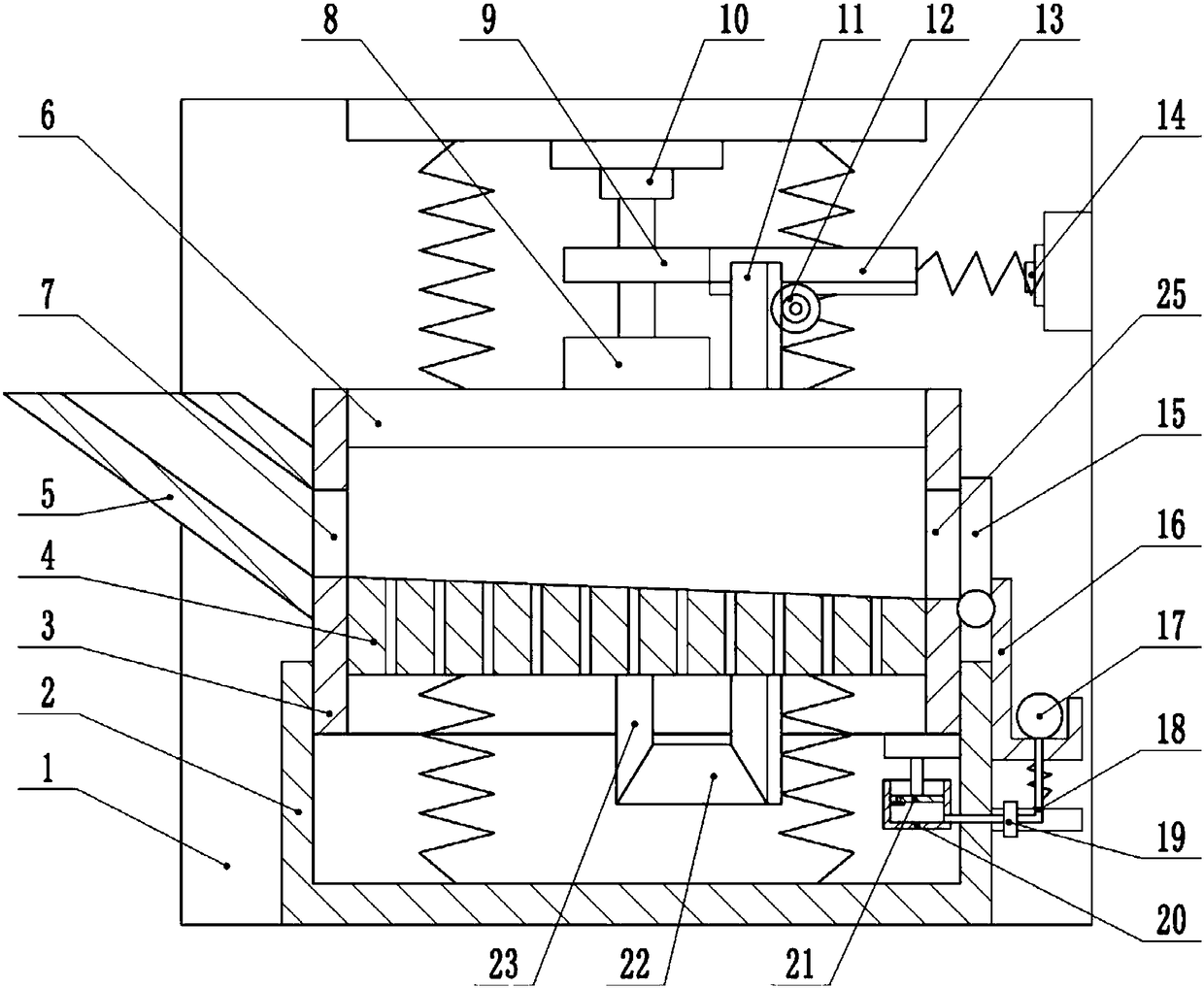

The invention discloses a gear assembly driving type swing type seed draining device. The device comprises a device body, wherein the device body is provided with a base, a draining chamber is arranged on the base, rotating shafts are arranged in the draining chamber, and draining containing grooves are formed below the rotating shafts; and the device body is provided with power cabins, driving devices are arranged inside the power cabins, and the driving devices are mainly composed of main driving gears, auxiliary driving gears, incomplete gears, driving racks and connecting plates. Accordingto the gear assembly driving type swing type seed draining device, the structure is simple, and seeds placed inside the draining containing grooves are subjected to centrifugal action in a swing mode, so that the seed draining efficiency is improved, compared with an existing static draining mode, the effect of the swing mode is better, compared with a drum rotation draining mode, the seeds are prevented from being damaged through the swing mode, the use is convenient, and the practicability is high.

Owner:黄锦山

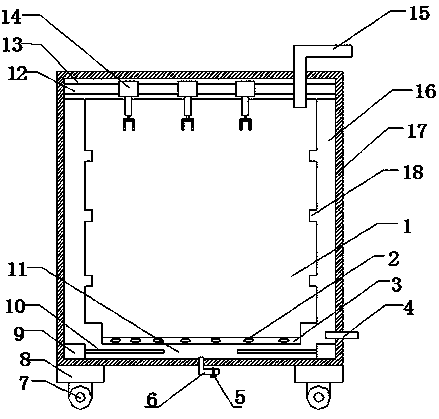

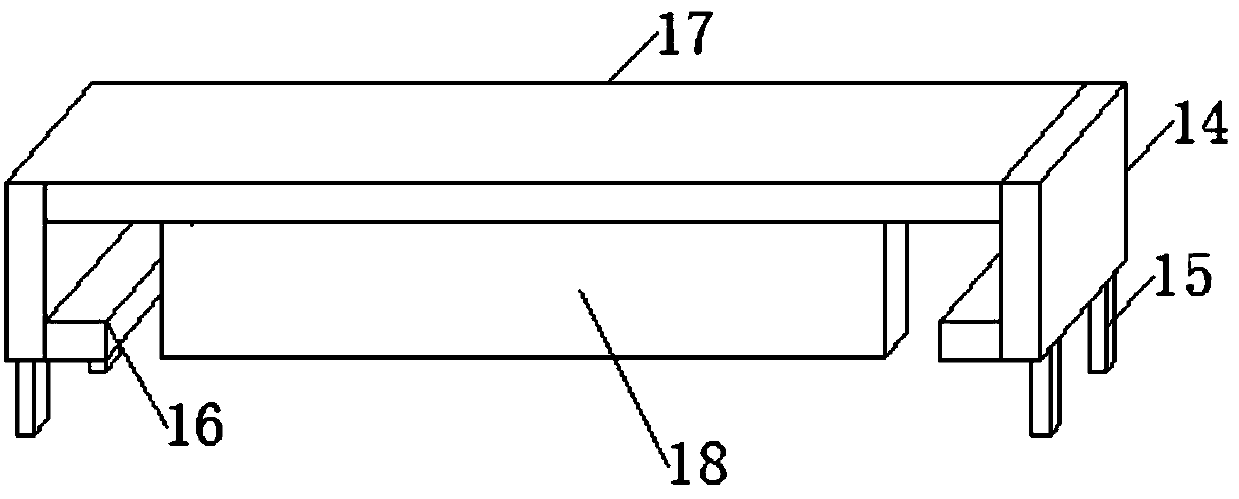

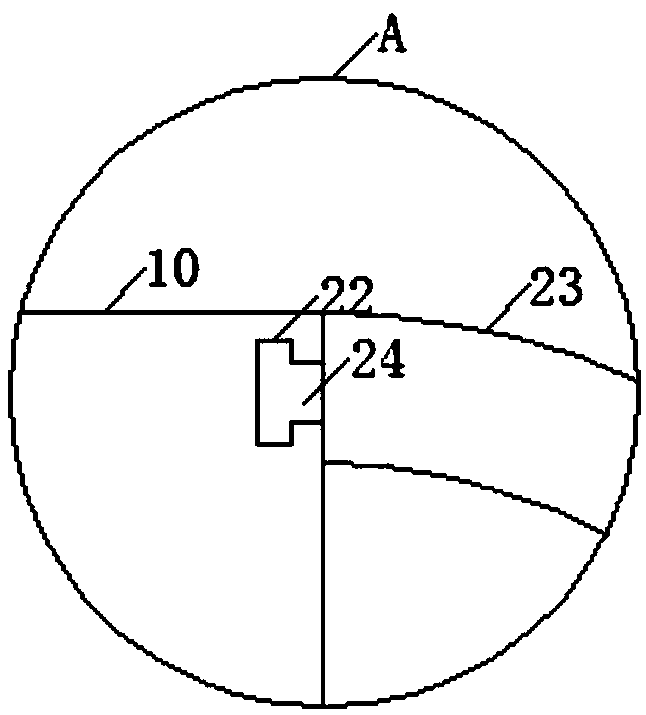

Timber cooking equipment for processing furniture

InactiveCN108162110ADrain fastImprove draining efficiencyWood treatment detailsWood impregnation detailsEngineeringDrain efficiency

The invention relates to timber cooking equipment for processing furniture. The timber cooking equipment comprises a box body, wherein a water tank is arranged at the bottom of the box body; heaters are arranged on two sides of the water tank; a steam layer is arranged on the upper surface of the two sides of the water tank in a communicating manner; a cross beam is in rivet joint with the bottomof the steam layer; a guide rail is arranged on the cross beam; a clamping device is mounted on the guide rail; a laminated plate is arranged on the upper surface of the water tank; a steam hole is formed in the laminated plate; an air hole is formed in a position, close to the inner side of the box body, of the steam layer; the box body is provided with a lateral lower part; the lateral lower part is connected with a water inlet; the upper right corner of the box body is connected with an air conveying pipe; and a drain pipe is arranged at the bottom of the center of the water tank. The timber cooking equipment is simple in structure and convenient to use, combines cooking and drying, saves time, and reduces the steps to enable the timber drying speed to be higher and improve the timber draining efficiency.

Owner:成都纽凯尔斯家具有限公司

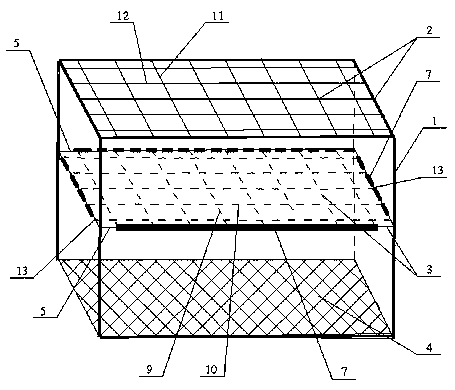

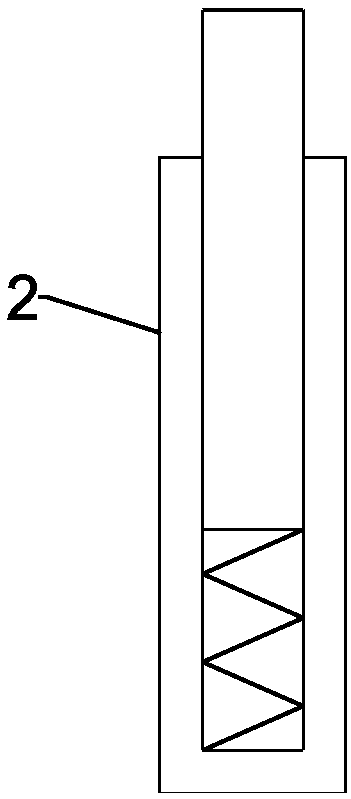

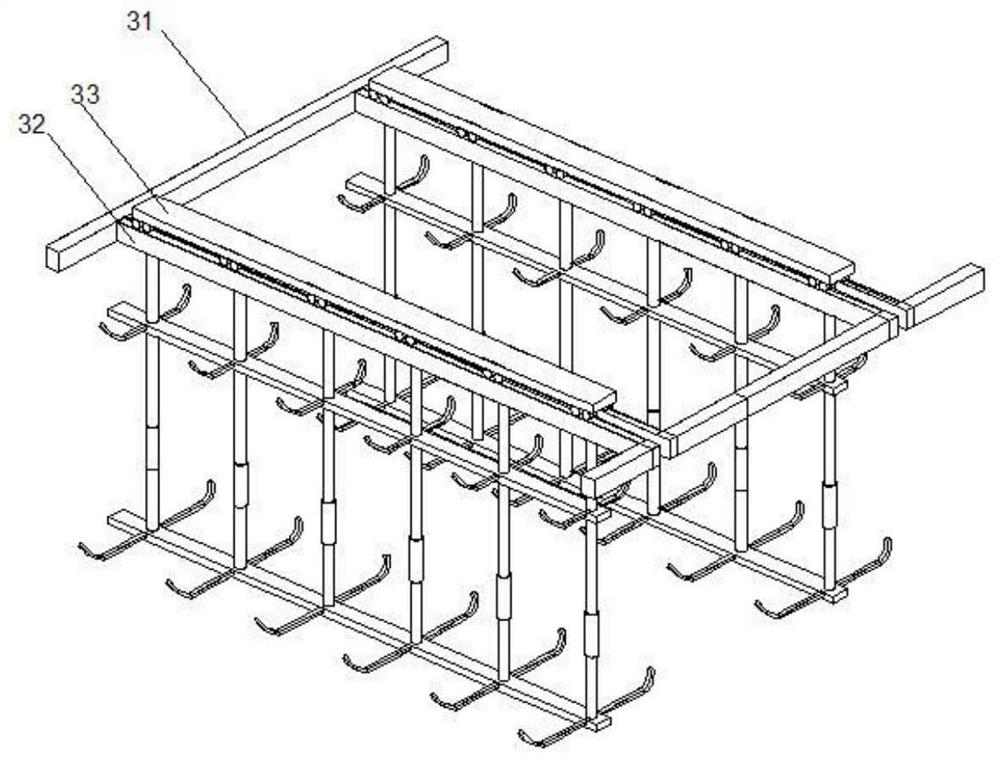

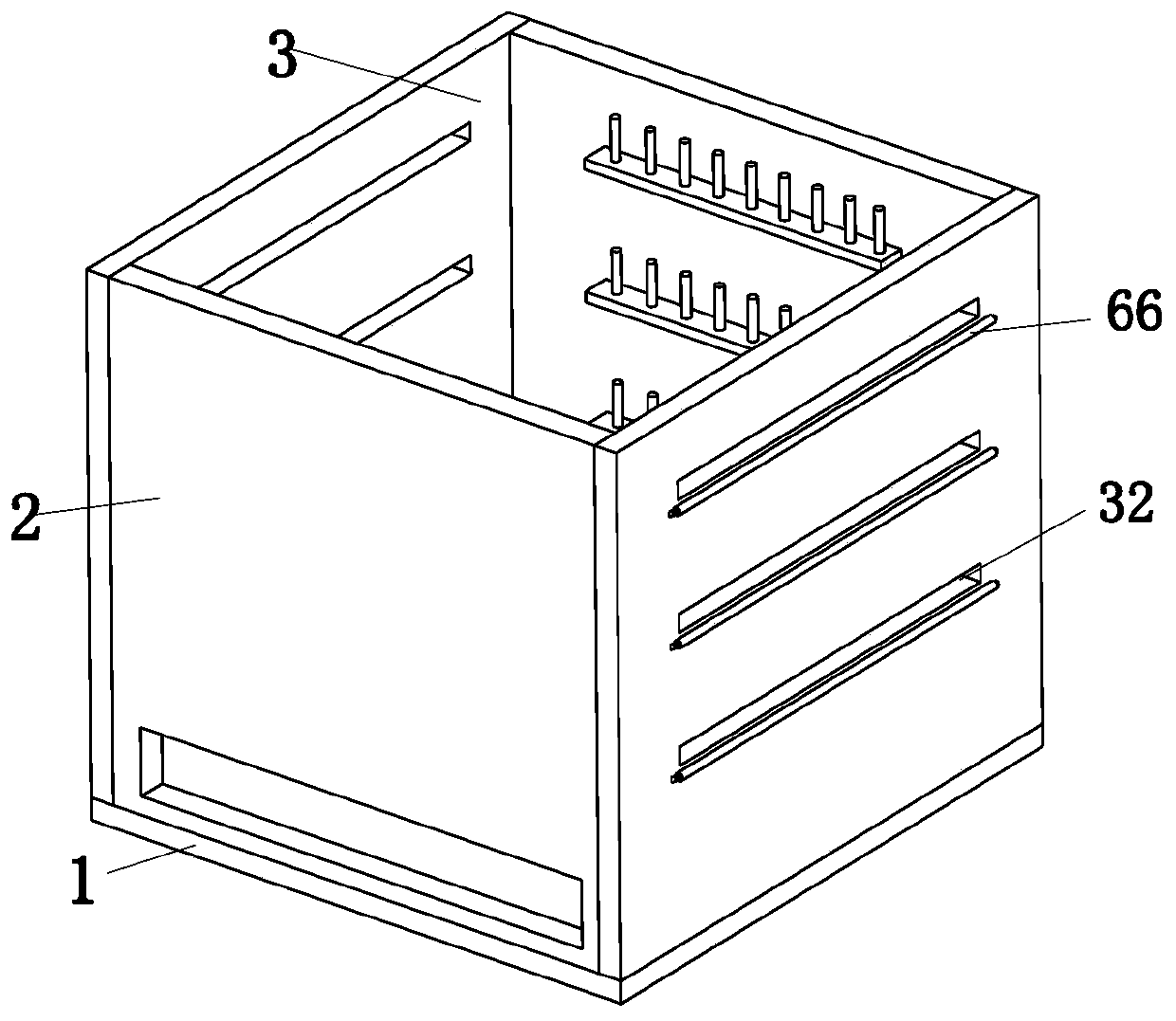

Widely-applied test tube rack

InactiveCN105498887AReduce side to side shakingAvoid shaking from side to sideTest tube stands/holdersLaboratory testTest tube

The present invention discloses a widely-applied test tube rack comprising a frame, the frame is provided, from top to bottom, with a top layer, a middle layer and a bottom layer, the top layer comprises a top layer mesh structure comprising a top layer transverse line and a top layer longitudinal line, the middle layer comprises a middle layer mesh structure comprising a middle layer transverse line and a middle layer longitudinal line, both sides of the intermediate layer transverse line are connected to a sliding rod on a transverse connecting rod, both ends of the intermediate layer longitudinal line are connected to a sliding rod on a longitudinal connecting rod, the sliding rods sleeve the transverse connecting rod and the longitudinal connecting rod, the transverse connecting rod and the longitudinal connecting rod are respectively provided with a scale hole, and the sliding rods are respectively provided with a fixing hole. The test tube rack has the advantages of being easy to use, easy to operate, capable of making full use of the advantages of the test tube rack and reducing laboratory test tube rack waste, material-saving, small in floor space, and the like.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

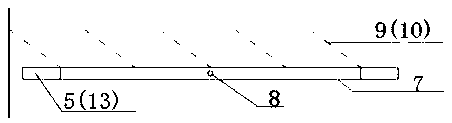

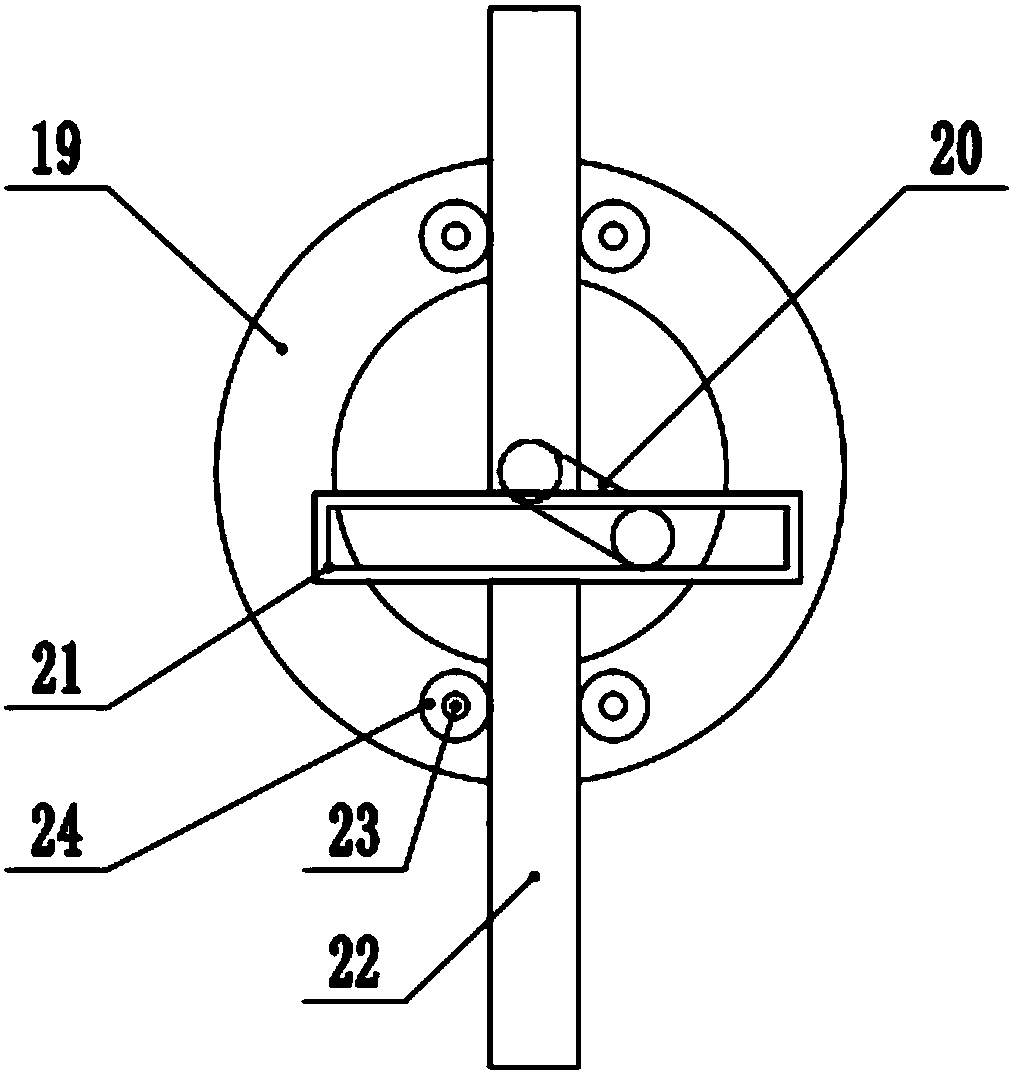

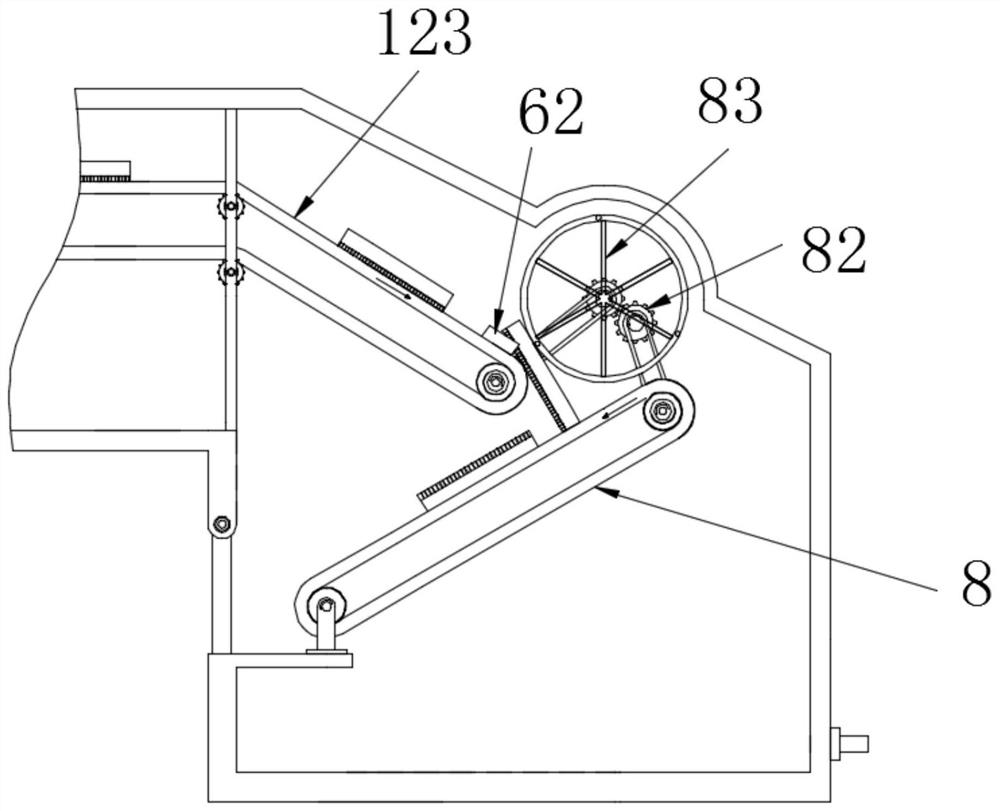

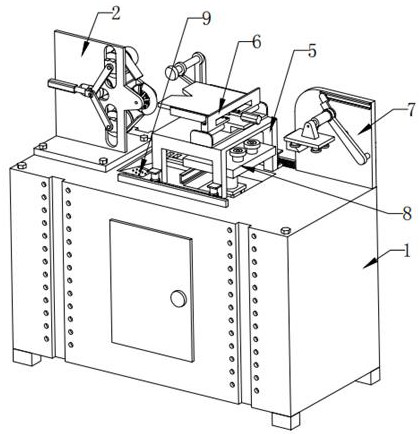

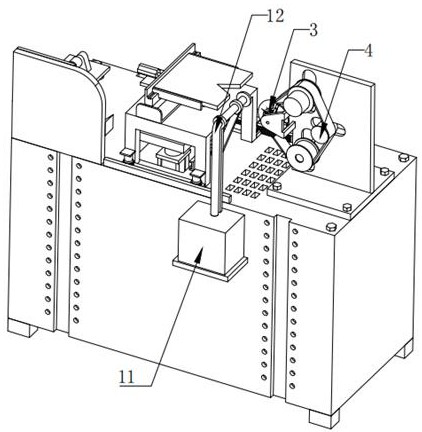

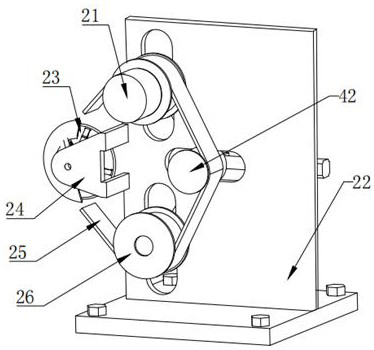

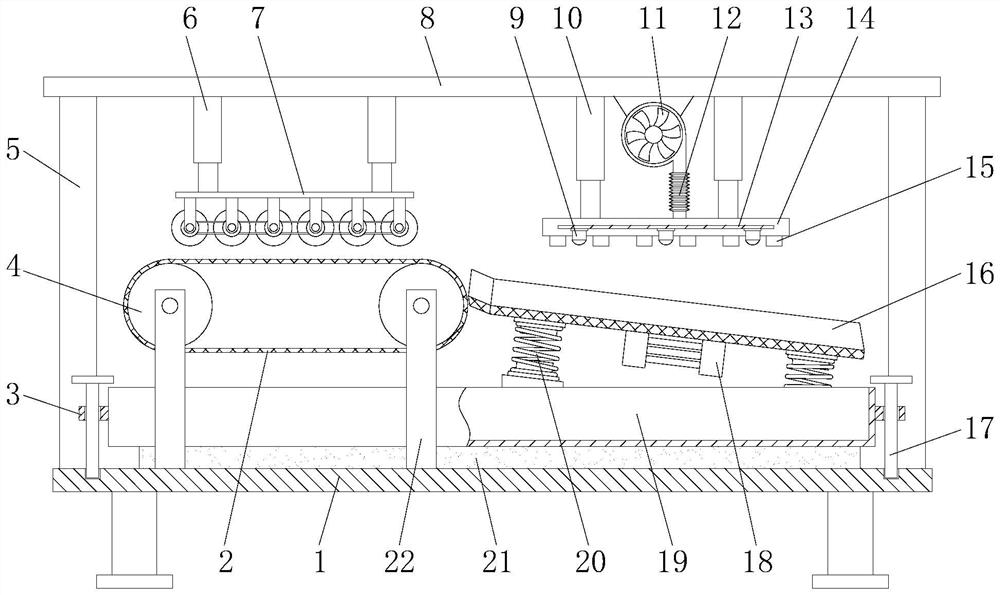

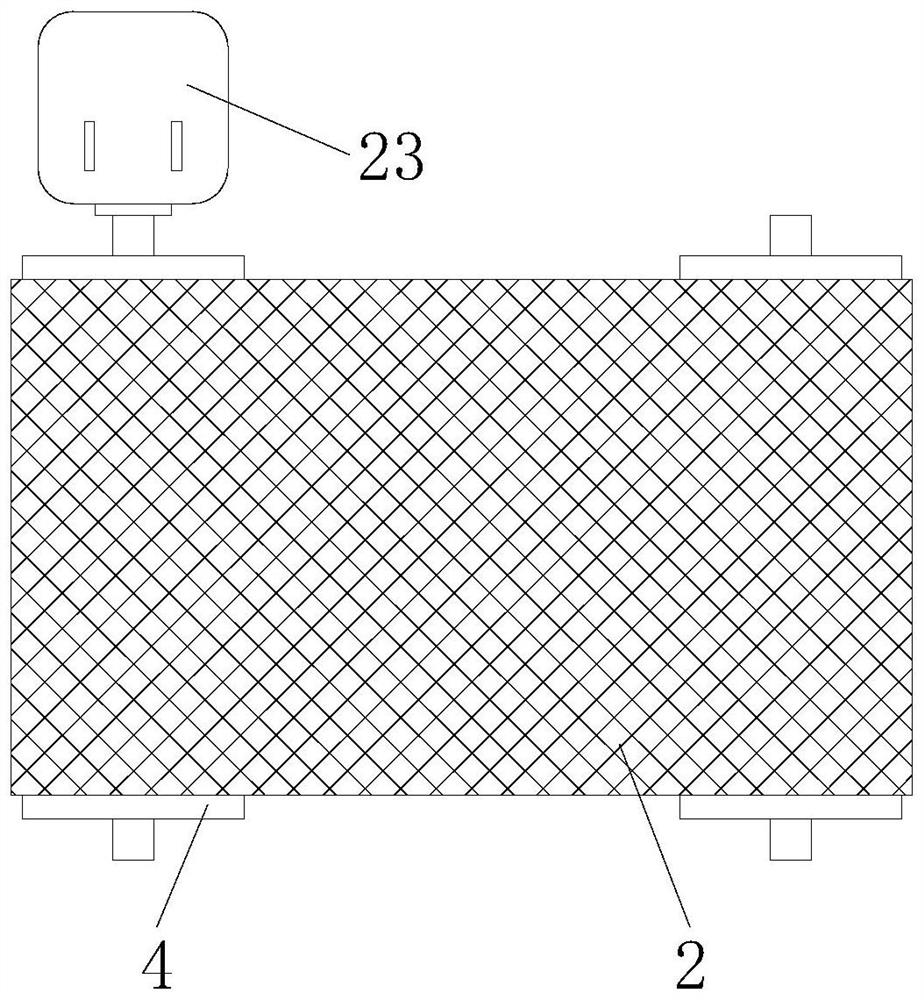

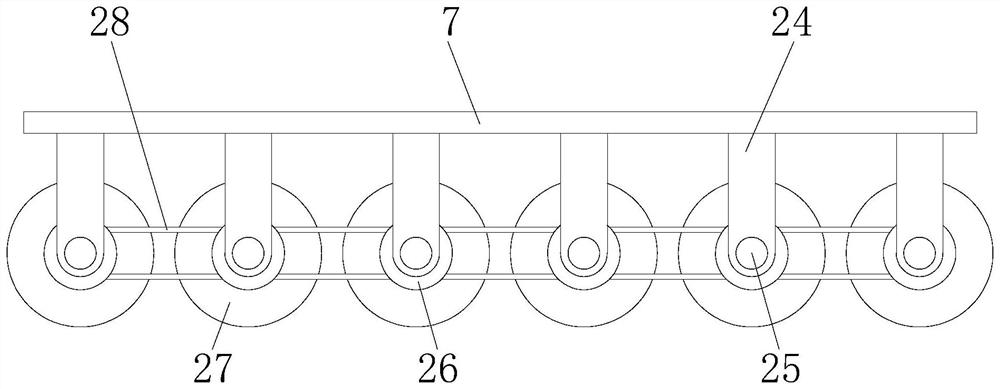

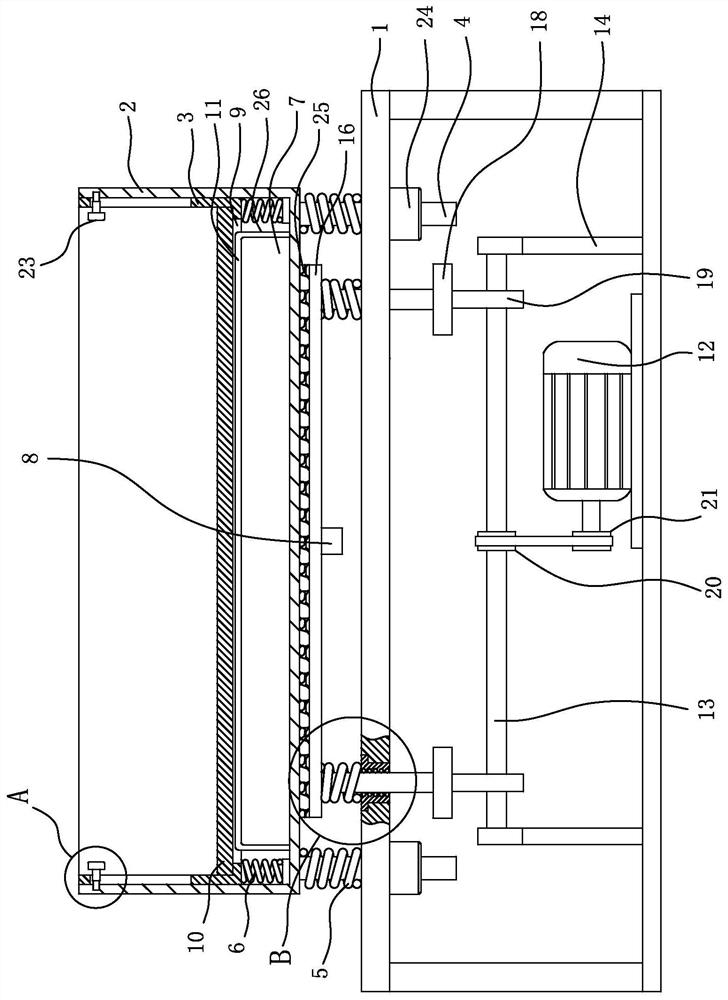

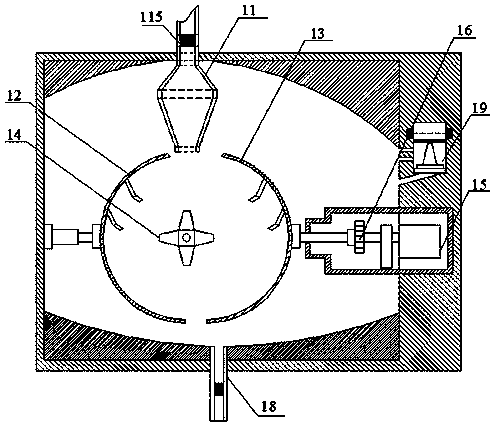

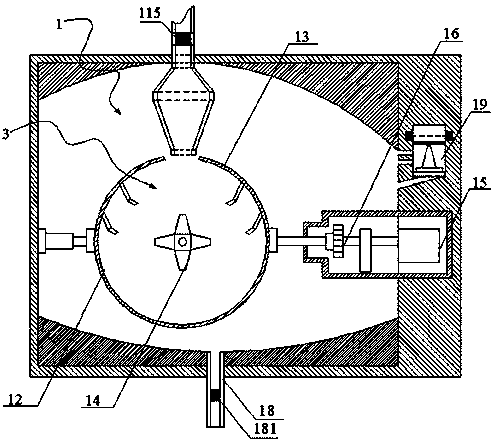

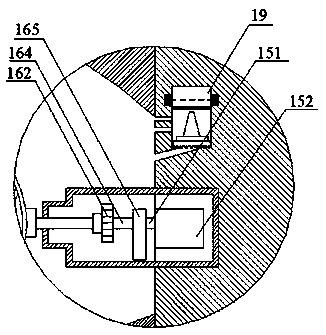

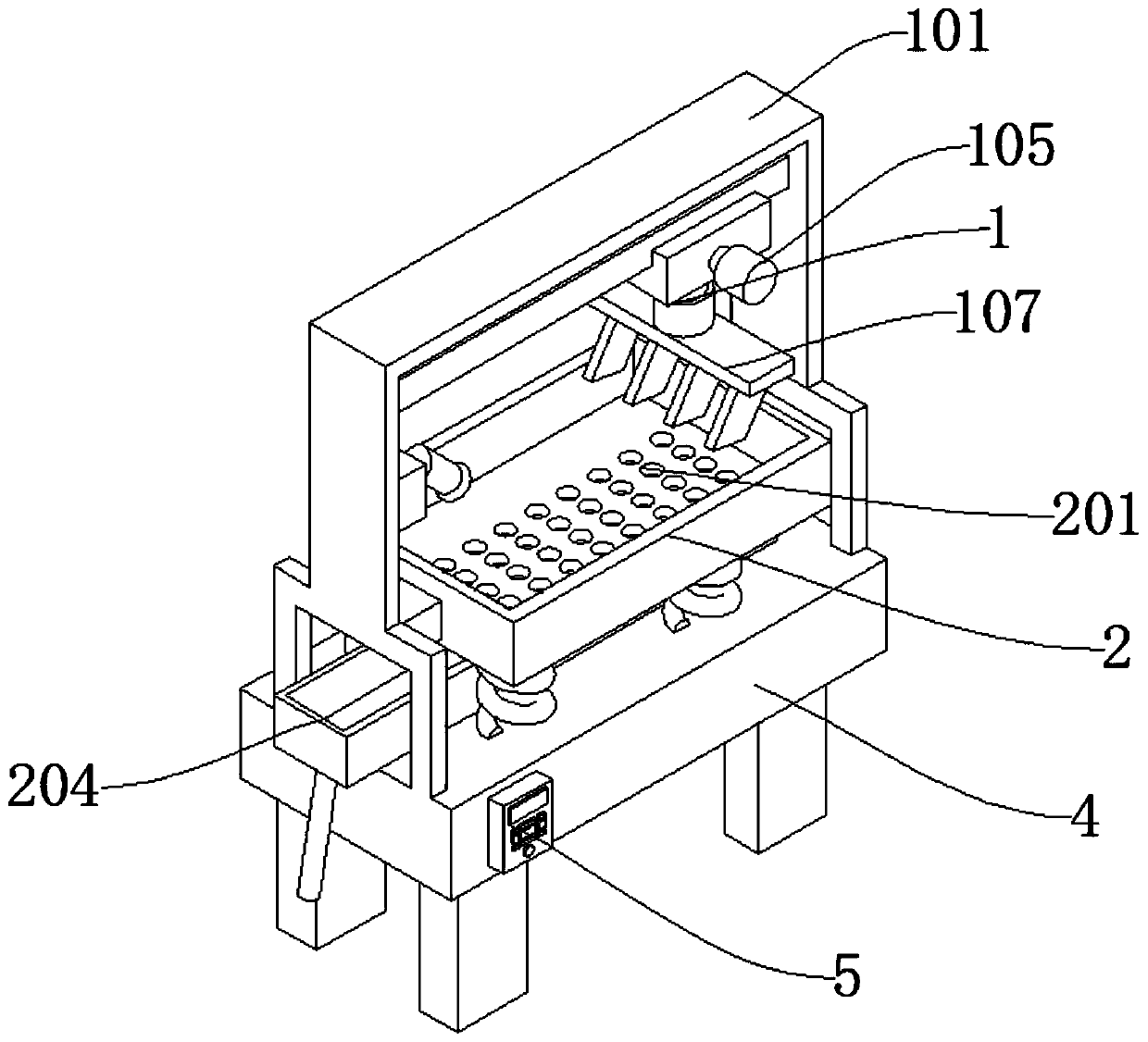

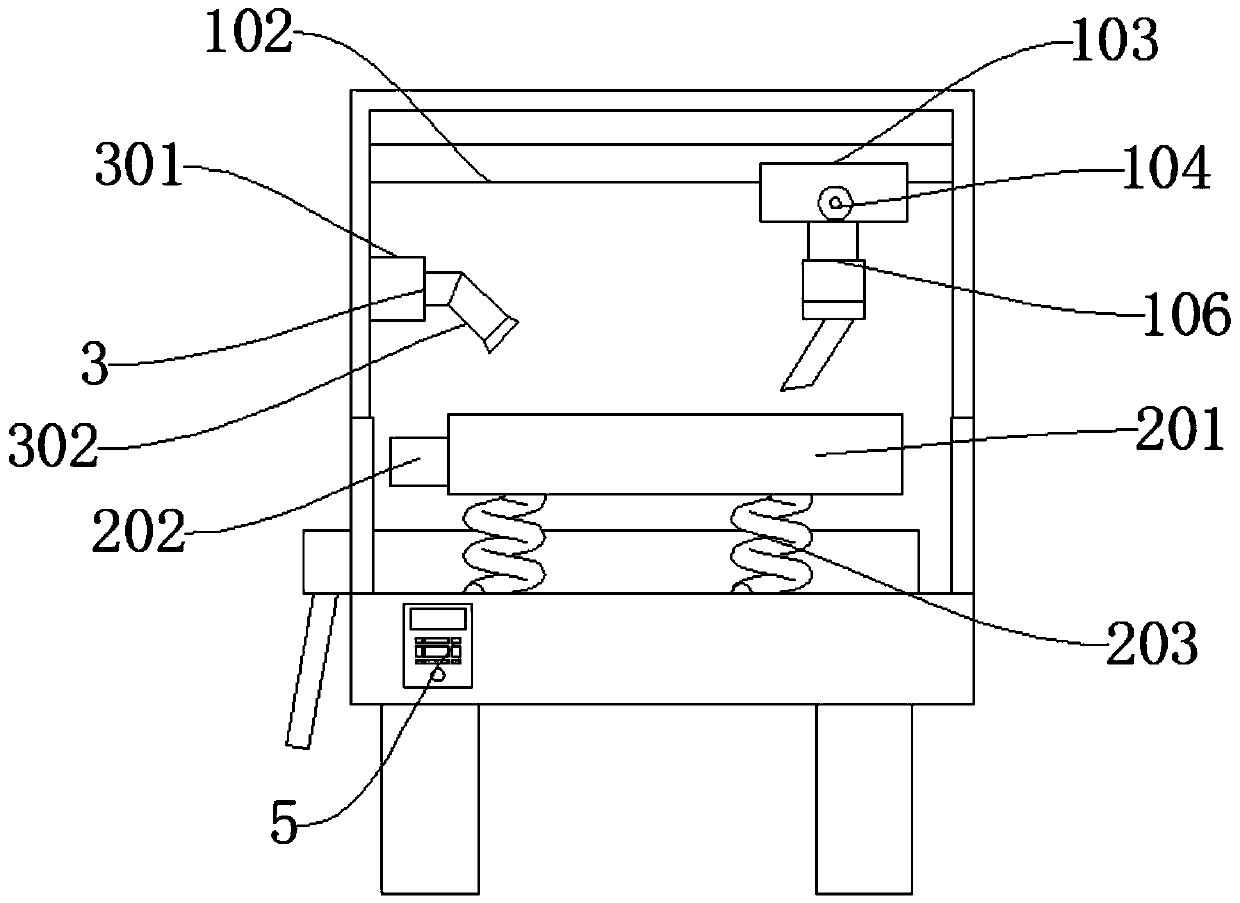

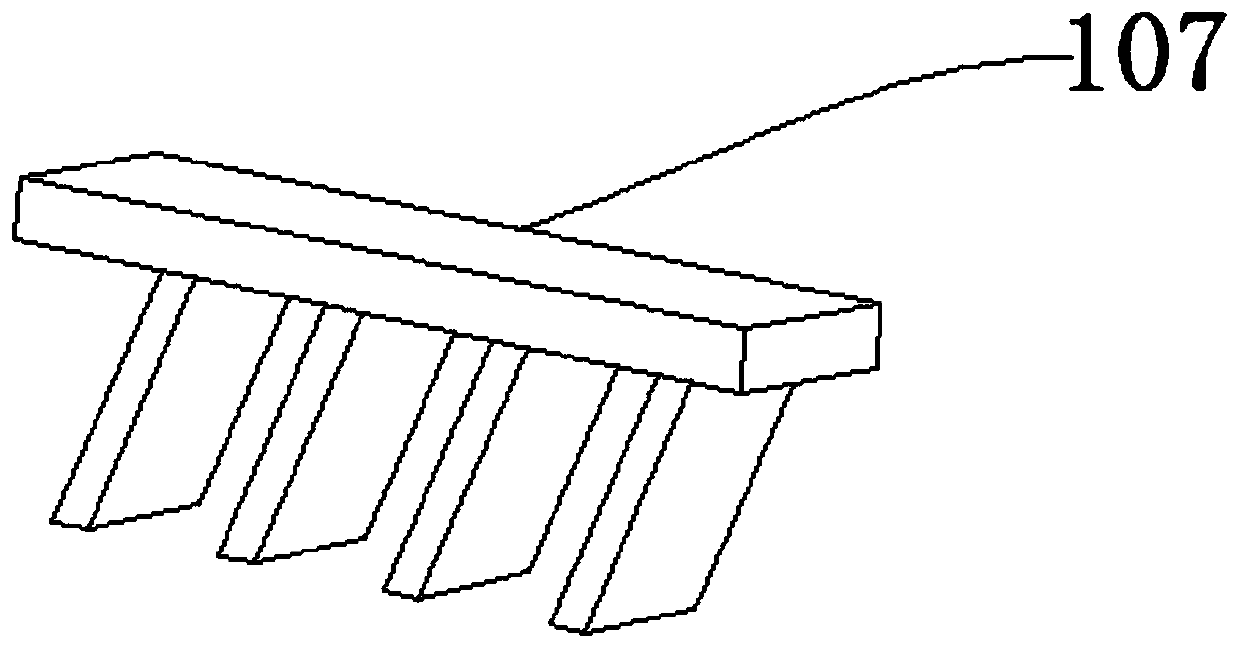

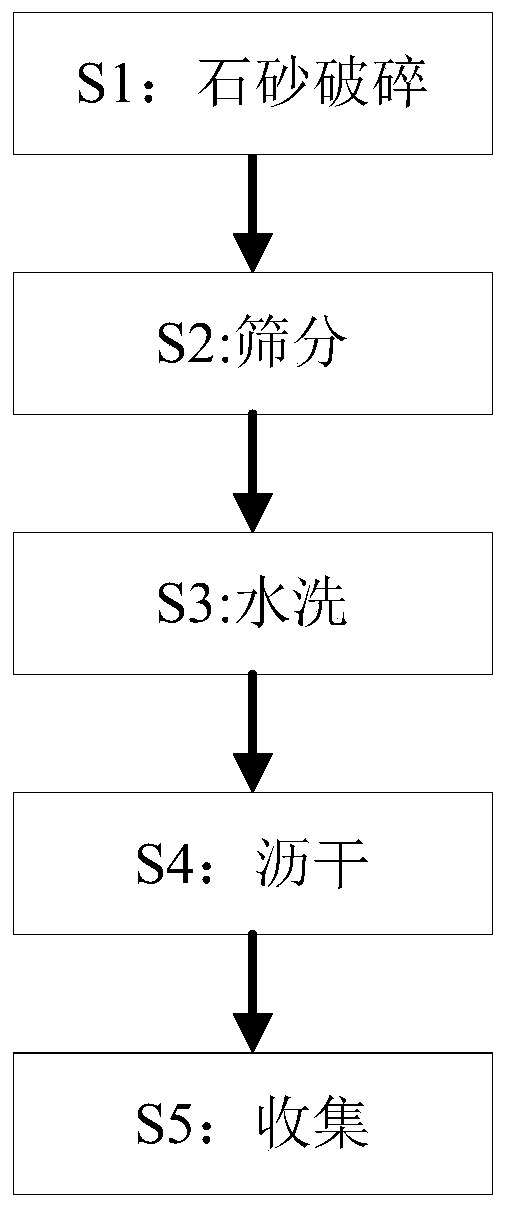

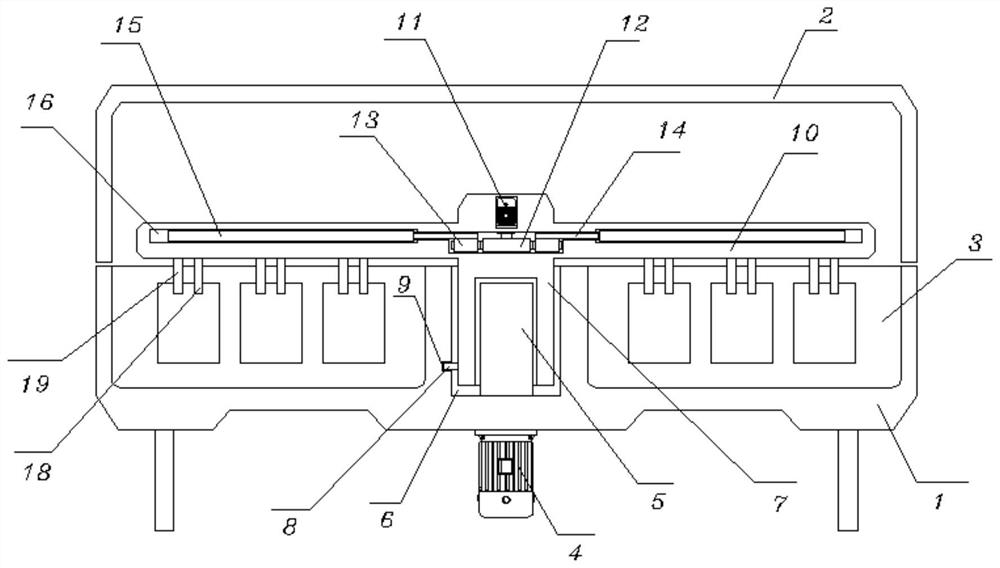

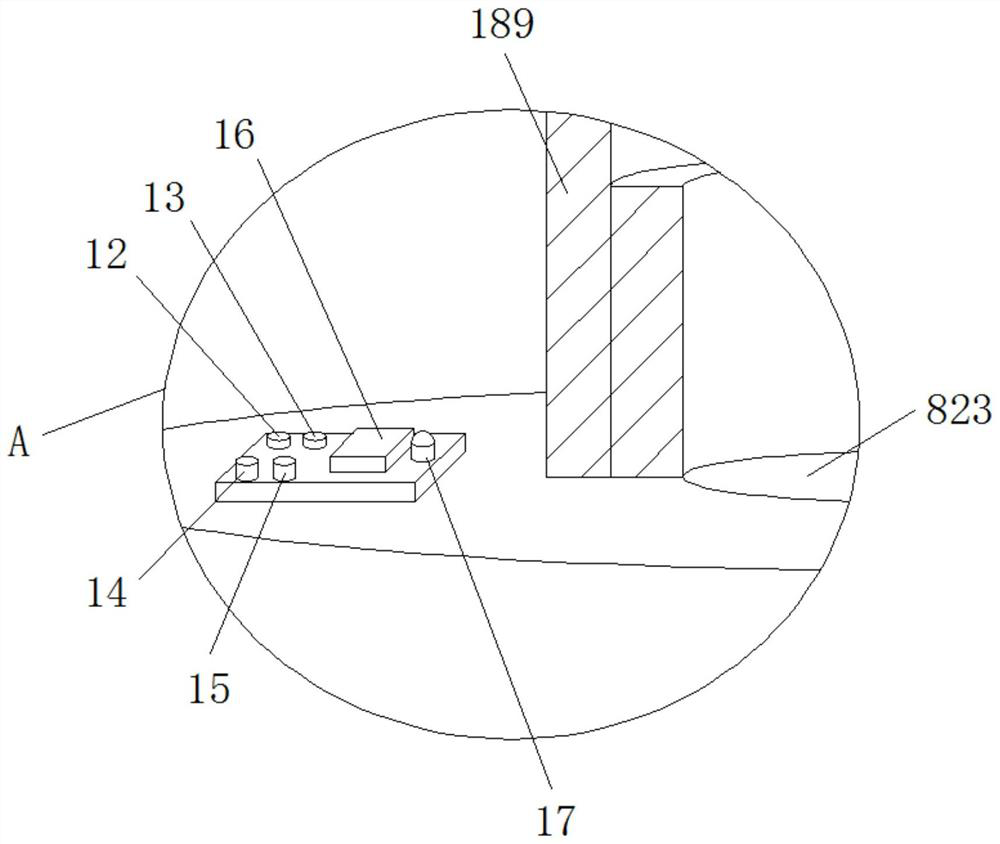

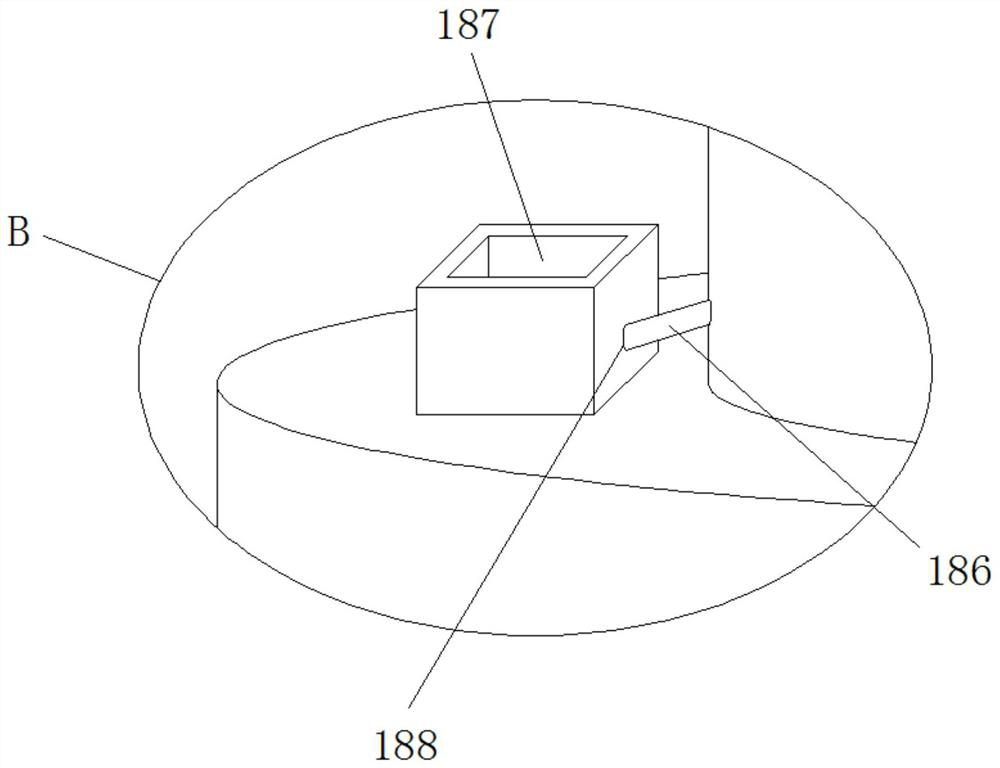

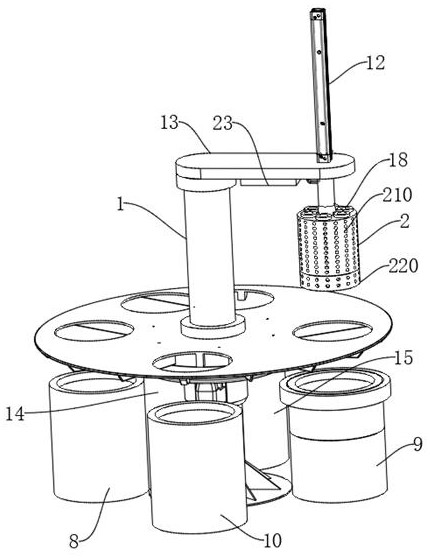

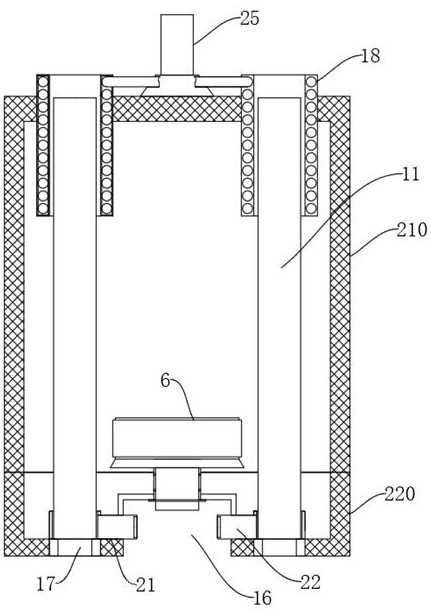

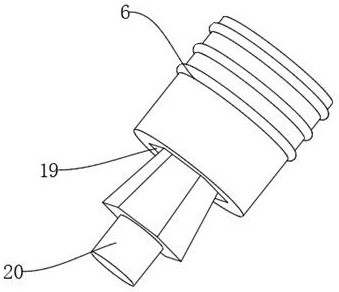

Impact component driven swing-type seed draining device

InactiveCN108552309AImprove draining efficiencyAvoid damageSeed preservation by dryingFood treatmentCentrifugationEngineering

The present invention discloses an impact component driven swing-type seed draining device. The impact component driven swing-type seed draining device comprises a device main body; the device main body is provided with a base; a draining chamber is arranged on the base; rotating shafts are arranged inside the draining chamber; draining placement grooves are arranged below the rotating shafts; thedevice main body is provided with power cabins; the inside of each power cabin is provided with a driving device; and each driving device mainly consists of a fixing plate, a rotating arm, a slidingframe, an impact rod, limit columns and rotating sleeves. The impact component driven swing-type seed draining device is simple in structure; a swing method is used to conduct centrifugation on seedsinside the draining placement grooves; the efficiency of the seed draining is improved; better effects are achieved by using the swing-type seed draining device than those of existing static draining;and the swing-type seed draining device prevents the seeds from being damaged compared with the method of rolling cylinder rotary draining, and is convenient to use and high in practicality.

Owner:黄锦山

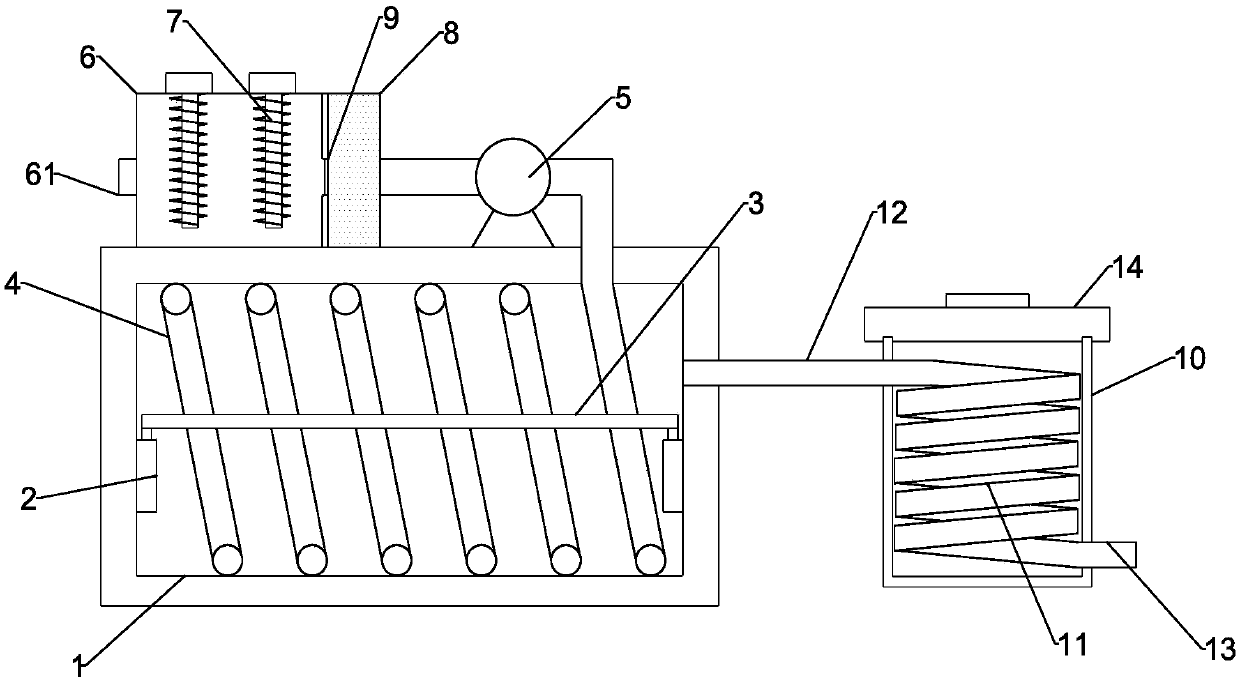

Energy-saving airflow drying box

InactiveCN108050827APromote shakingShake evenlyDrying gas arrangementsHeating arrangementEngineeringHot Temperature

The invention discloses an energy-saving airflow drying box, which comprises a box body, elastic supports, a placement screen plate, drying air pipes, an air pump, a heating box, a drying and cleaningbox, a water tank and a heat exchange pipe. The elastic supports are arranged on two sides in the box body; the placement screen plate is arranged on the elastic supports; the drying air pipes are arranged in the box body; the air pump, the heating box and the drying and cleaning box are arranged on the box body; an air inlet is formed in the left end of the heating box; heating rods are connected into the heating box; a vent hole is formed between the heating box and drying and cleaning box; the water tank is arranged on the right side of the box body; the heat exchange pipe is arranged in the water tank; an air inlet pipeline is connected between the upper end of the heat exchange pipe and a right wall of the box body; an air outlet pipeline is connected to the right side of the lower end of the heat exchange pipe; and an upper cover is connected to the upper end of the water tank. According to the energy-saving airflow drying box provided by the invention, a material can be uniformly dried through a clean air flow, and the efficiency is improved through telescopic shaking of the elastic supports; and the waste heat of a high-temperature tail gas is fully utilized by utilizing the heat exchange pipe, so that the energy-saving airflow drying box is energy-saving and environmentally-friendly on the basis of ensuring favorable drying.

Owner:苏州艾捷尔斯生物科技有限公司

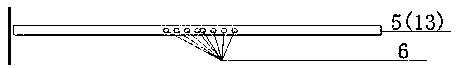

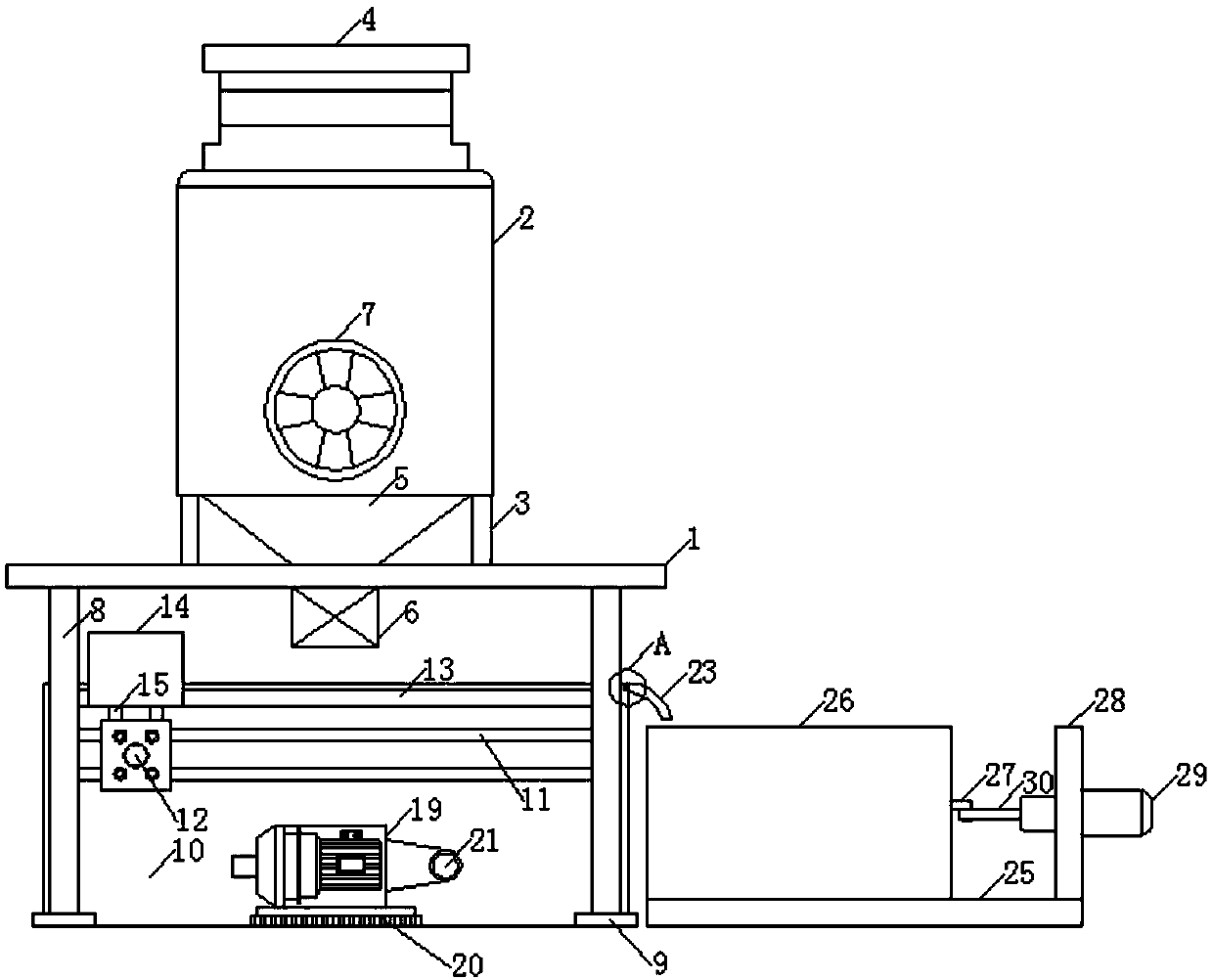

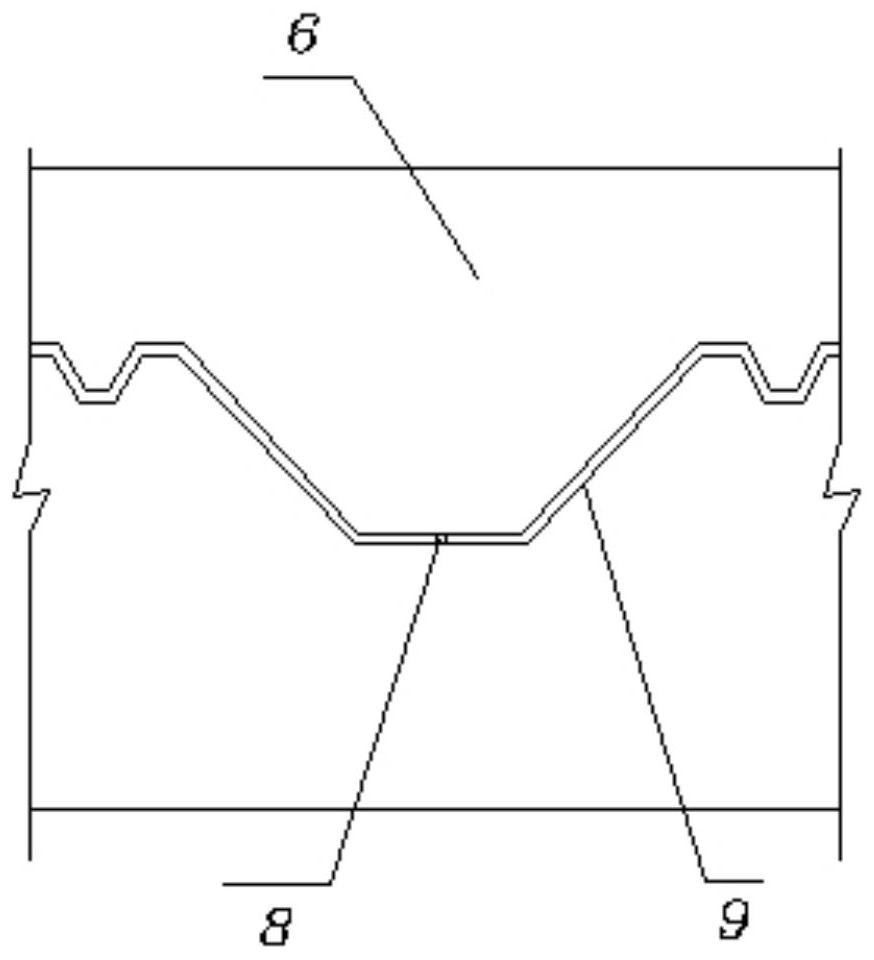

Draining device for processing of aquatic products

ActiveCN110953842AHigh speedImprove draining effectDrying solid materials without heatDrying chambers/containersReciprocating motionAquatic product

The invention discloses a draining device for processing of aquatic products. The draining device comprises a rack, an outer tank body, an inner tank body and a double-cam jacking mechanism, the outertank body is located above the rack and connected with the double-cam jacking mechanism, the double-cam jacking mechanism can drive the outer tank body to move in an up-down reciprocating mode, guiderods penetrating through the rack and being in sliding fit with the rack are arranged at the bottom of the outer tank body, and load-bearing compressed springs are arranged on the parts, between therack and the outer tank body, of the guide rods in a sleeving mode; and buffer springs are arranged at the tank bottom of the outer tank body, the inner tank body is located in the outer tank body andplaced on the buffer springs, a water collecting chamber is formed in a space between the inner tank body and the outer tank body, the bottom of the water collecting chamber is connected with a drainage tube, a plurality of draining long holes are formed in the tank bottom of the inner tank body at intervals, an overhead convex ridge is arranged at the positions, on the two sides of each draininglong hole, of the tank bottom of the inner tank body, and blocking rods fixed to the tank bottom of the outer tank body are arranged in the draining long holes and are in clearance fit with the draining holes. The draining device is novel in structure, convenient to use, stable in operation, good in draining effect and high in draining efficiency.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

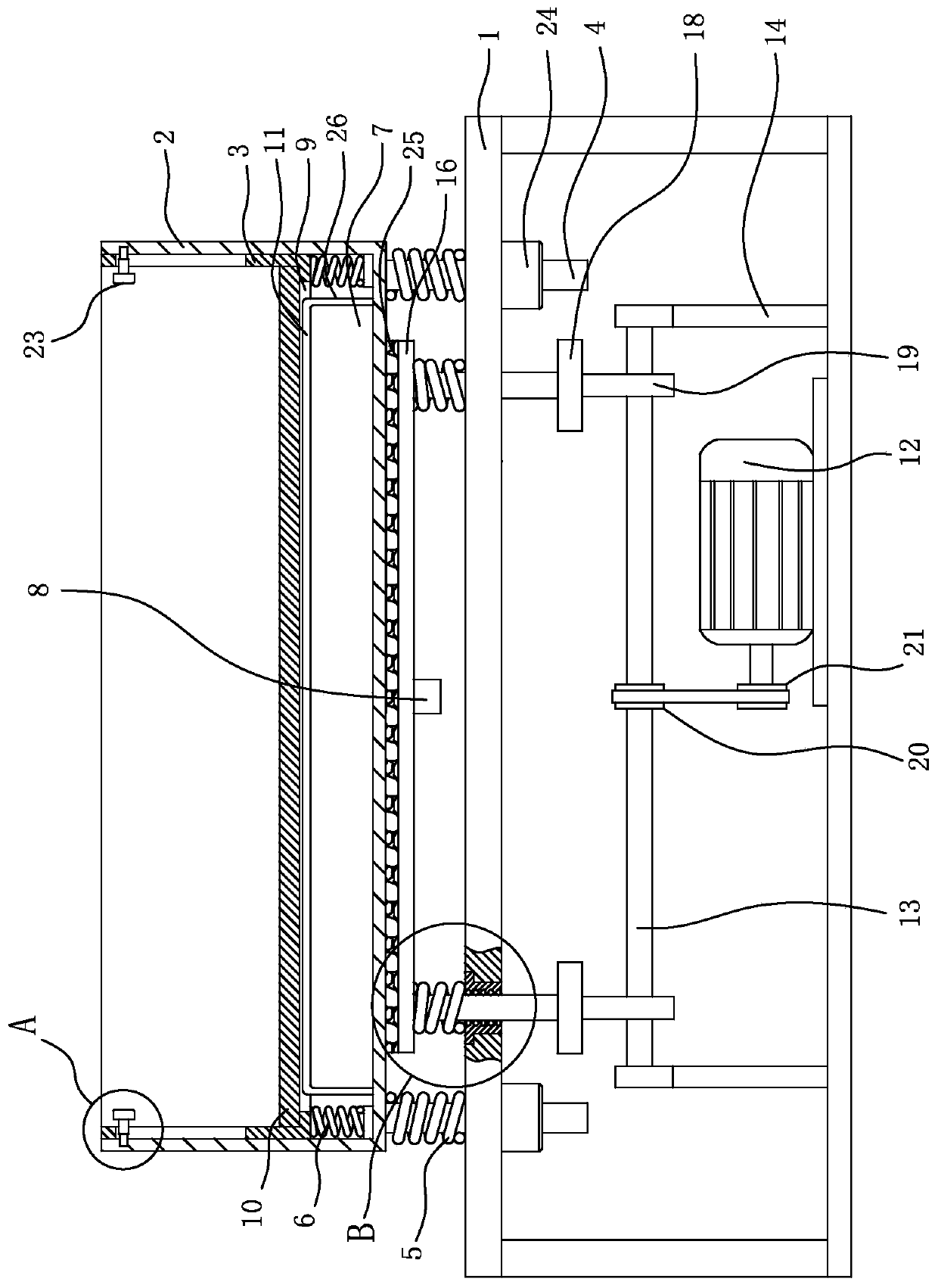

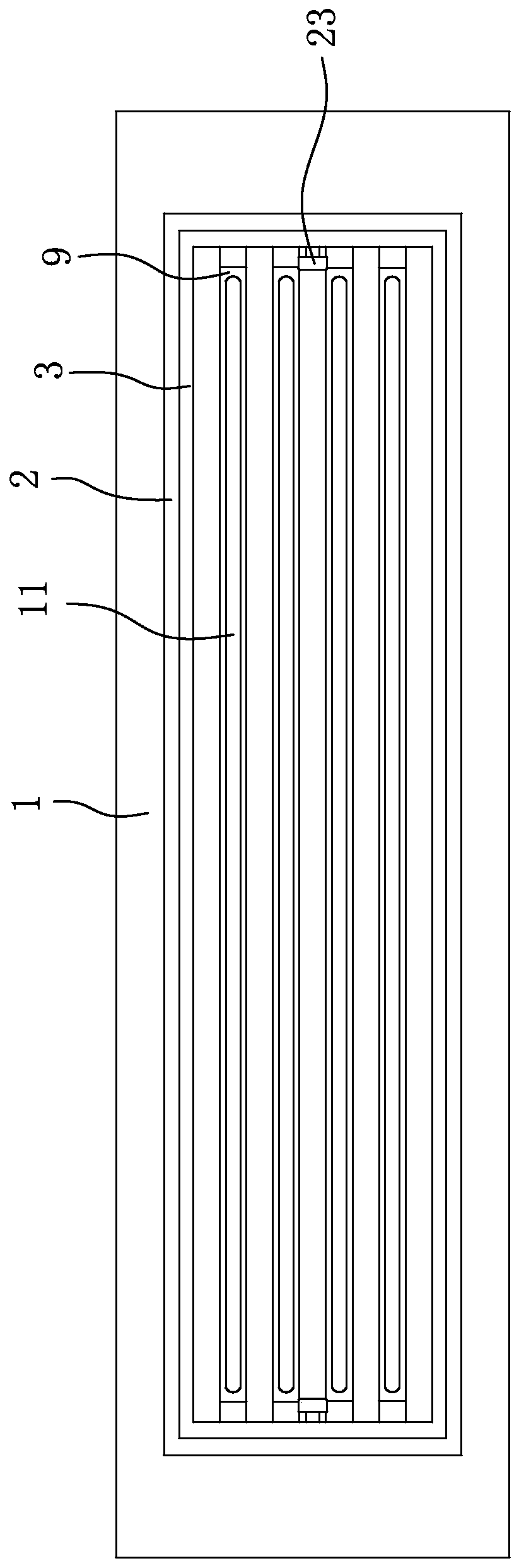

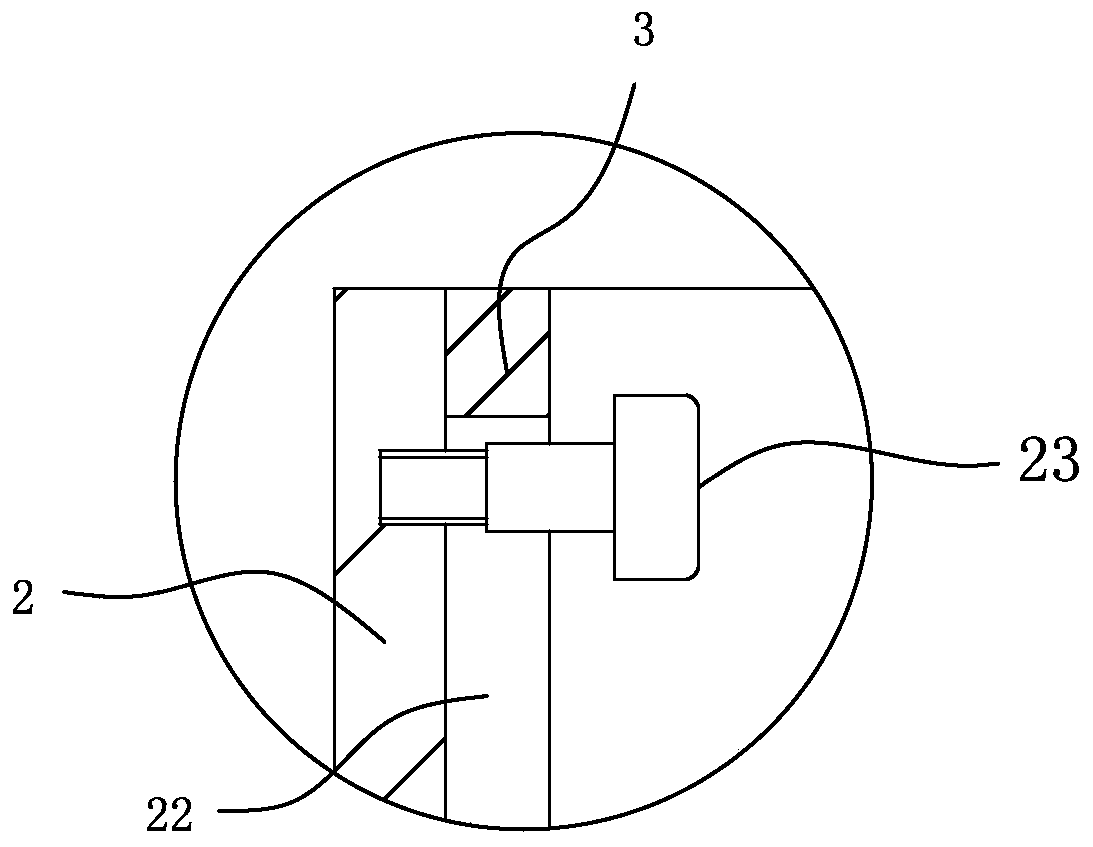

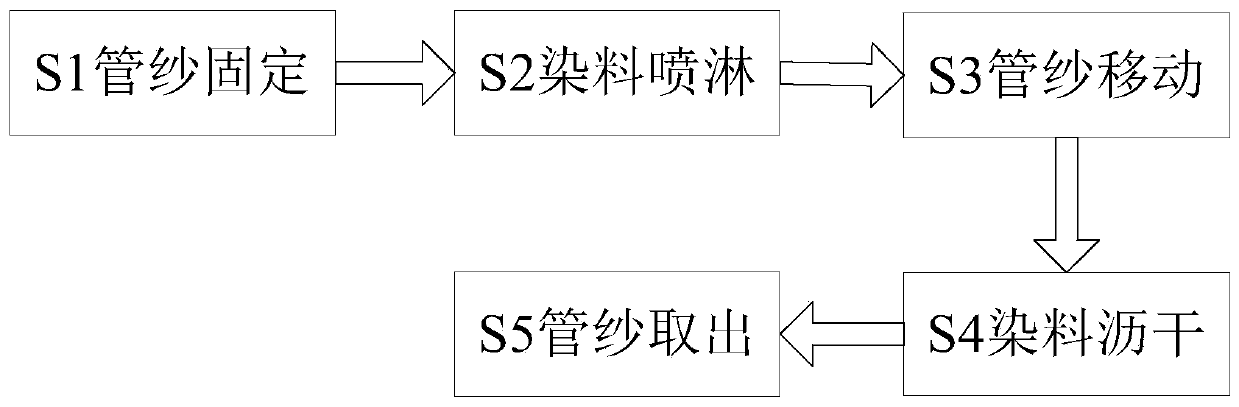

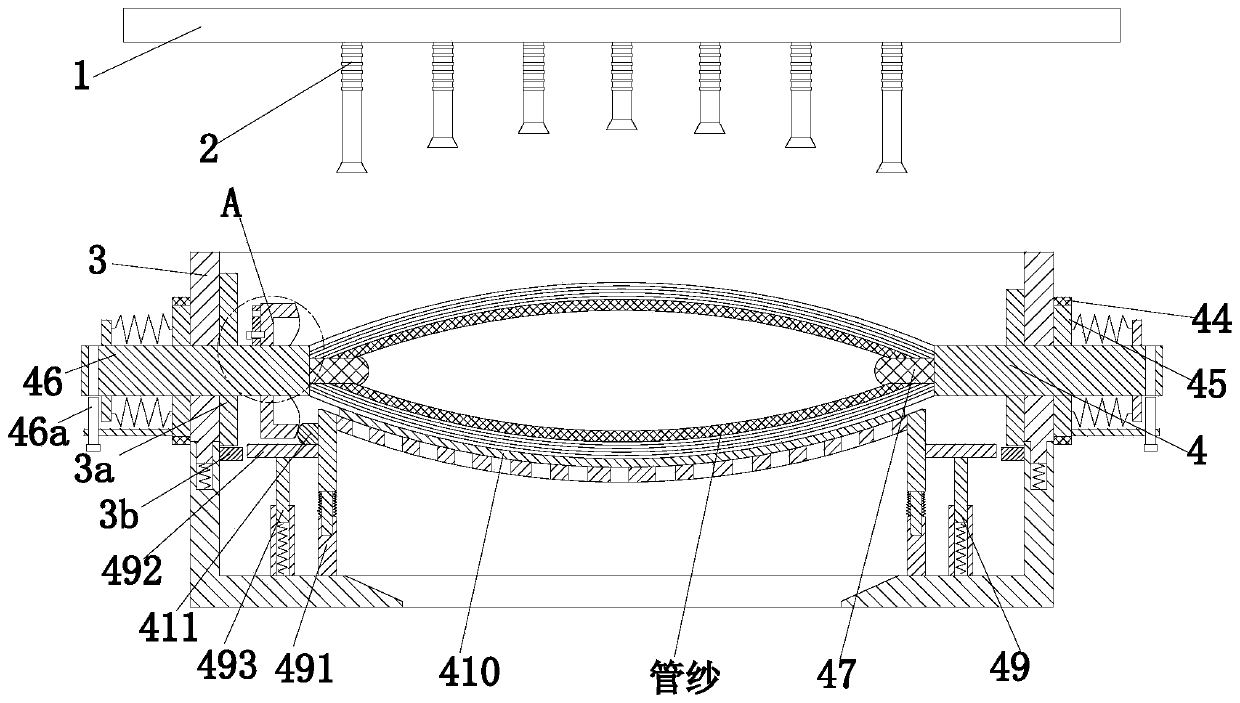

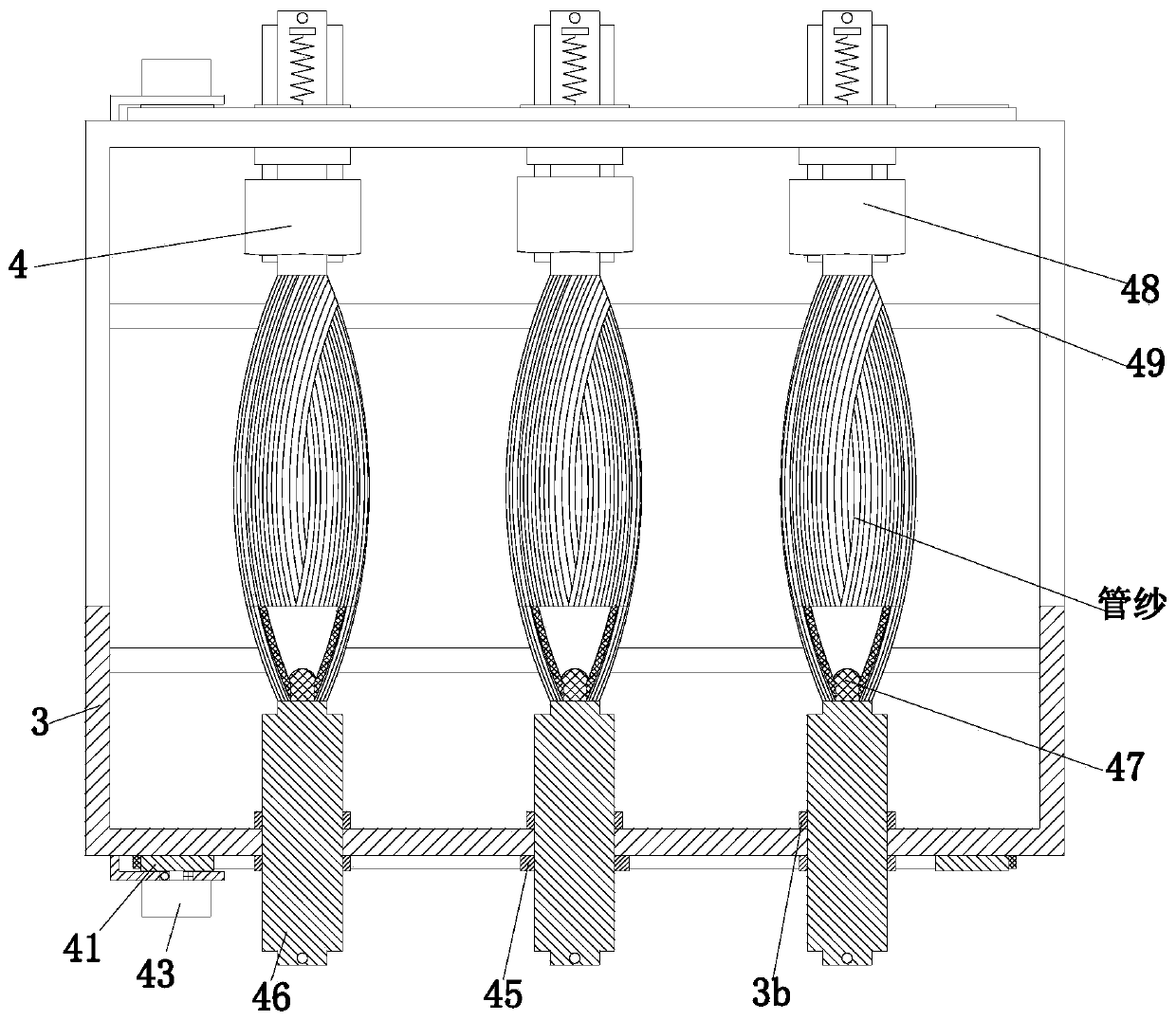

Textile bobbin yarn dyeing processing technology

InactiveCN111519369AEliminate DepthEliminate UniformityTextile treatment by spraying/projectingTextile treatment carriersYarnPolymer science

The invention relates to a textile bobbin yarn dyeing processing technology. Bobbin yarn dyeing processing equipment is used in the technology, and the bobbin yarn dyeing processing equipment comprises a top plate, a spraying pipe, a material containing box and a material containing mechanism. When the bobbin yarn dyeing processing equipment is adopted for dyeing bobbin yarn, the specific technological process comprises the steps of carrying out bobbin yarn fixing, dye spraying, bobbin yarn moving, dye draining and bobbin yarn taking out. The material containing mechanism comprises a driving roller, a driven roller, a driving motor, a conveying belt, a rotating ring, a clamping rod, a butt joint rod, a rotating piece, a supporting frame, an extrusion plate and a protruding block. Accordingto the textile bobbin yarn dyeing processing technology, multiple pieces of bobbin yarn can be dyed at the same time, during dyeing, the material containing mechanism can drive the bobbin yarn to rotate and meanwhile linearly move in the horizontal direction and the vertical direction relative to the spraying pipe, and therefore the purpose of expanding the spraying range of the spraying pipe isachieved; and after dyeing is completed, related components of the material containing mechanism are properly adjusted, the lower end of the bobbin yarn can be intermittently extruded, and therefore the purpose of extruding redundant dye liquor is achieved.

Owner:盛萍萍

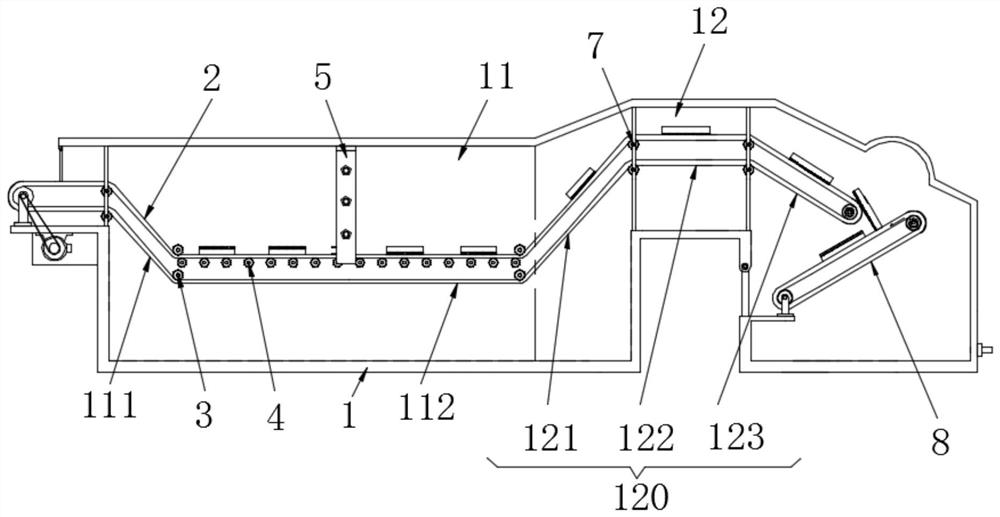

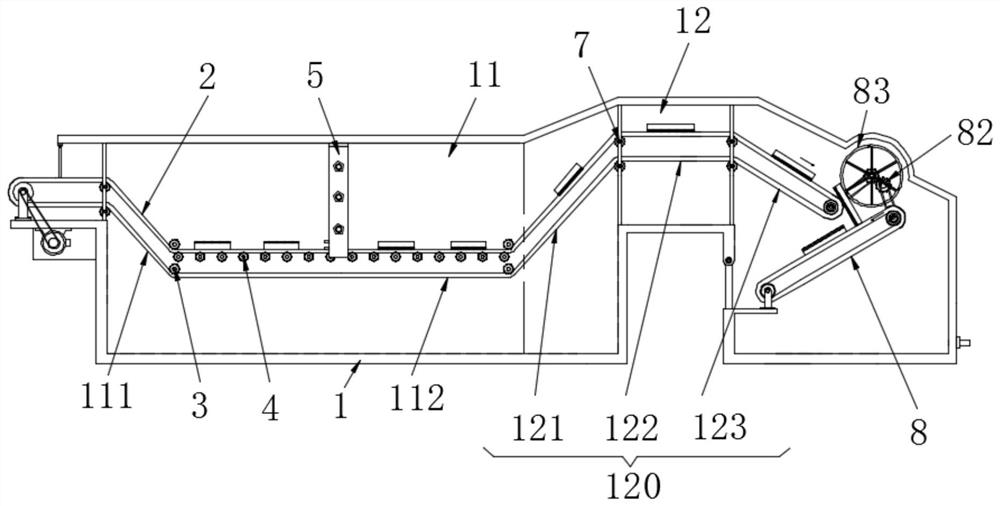

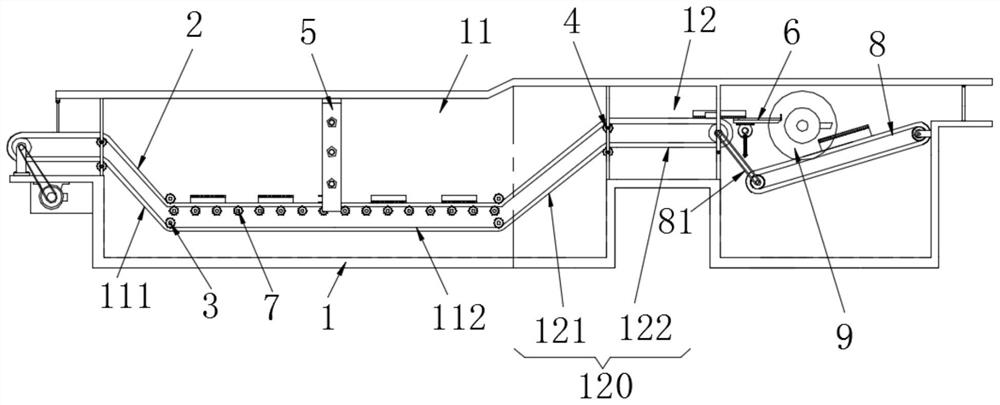

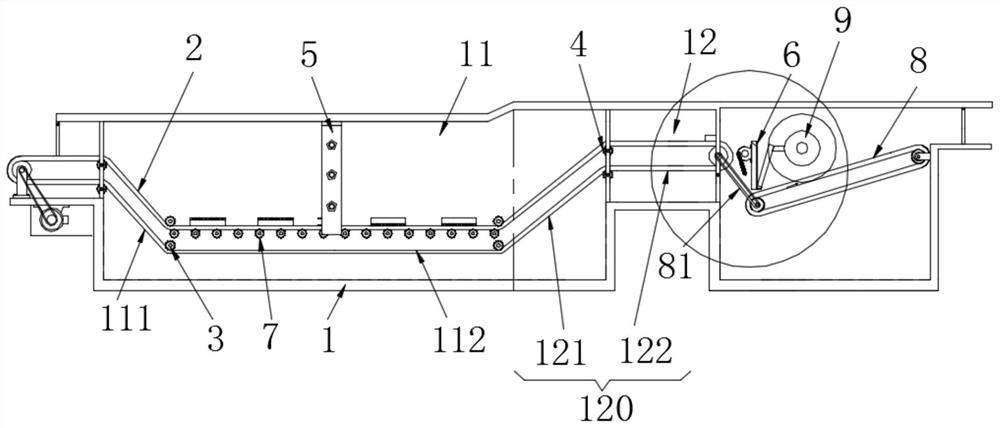

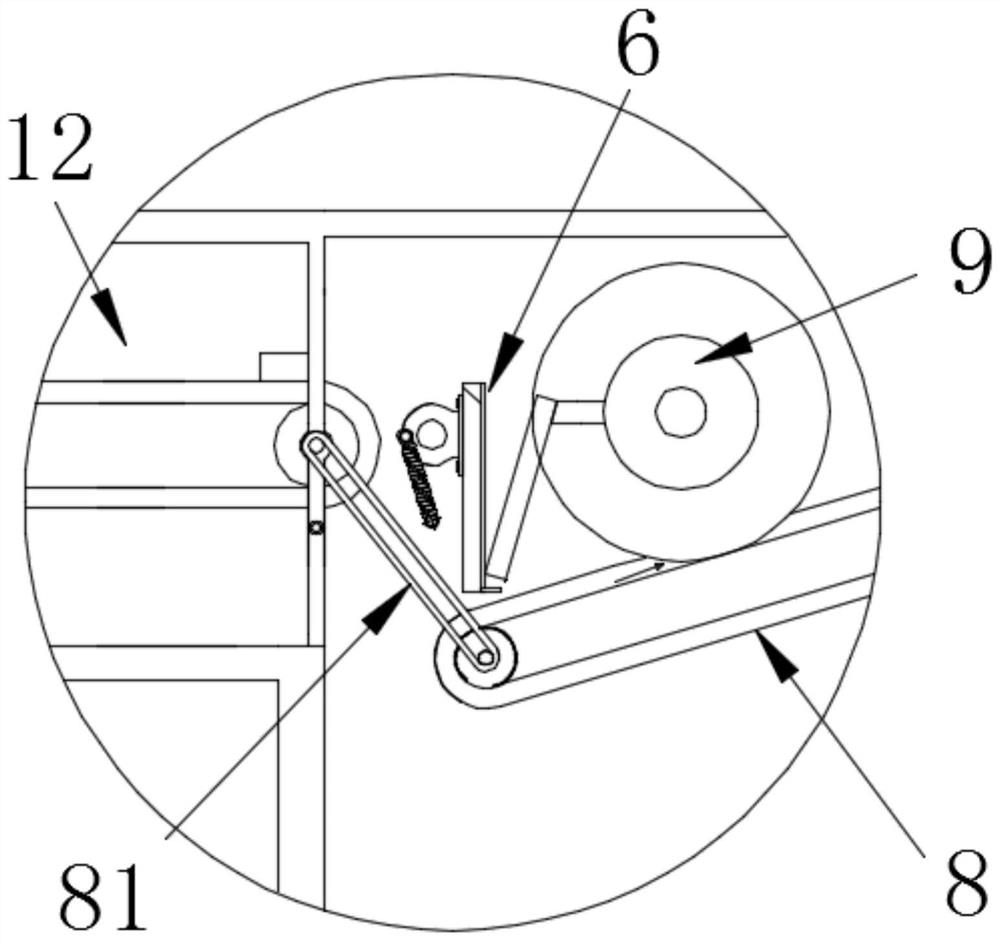

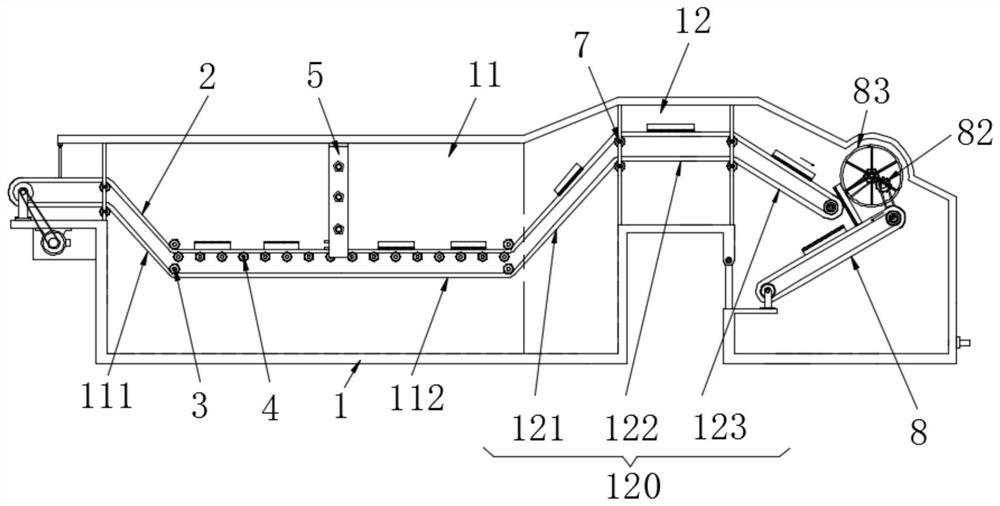

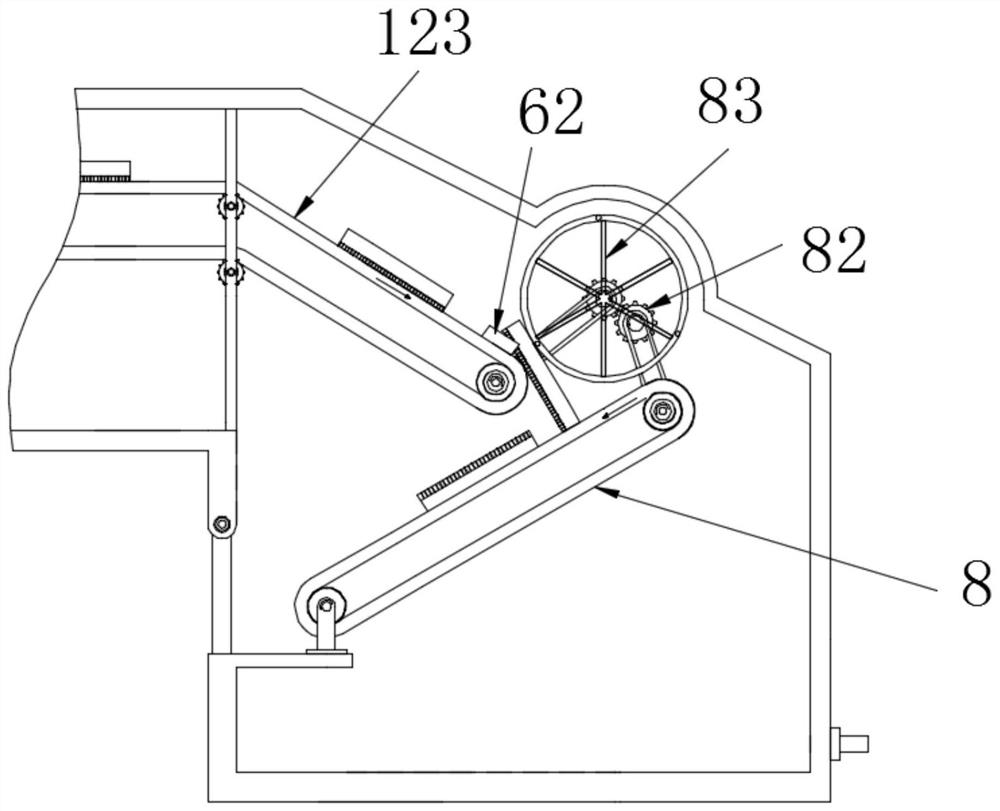

Turnover type draining device for pickling for radiator processing

ActiveCN112629227AAchieve two-way fast drainingImprove draining efficiencyConveyorsDrying chambers/containersEngineeringMechanical engineering

The invention discloses a turnover type draining device for pickling for radiator processing, and relates to the technical field of radiator processing. The turnover type draining device comprises a tank body and a secondary conveying belt; a conveying belt is arranged in the tank body, a pickling bin and a pickling solution draining bin are arranged in the tank body in the conveying direction, and the conveying belt is provided with a draining treatment section in the pickling solution draining bin; and the secondary conveying belt is arranged in the pickling solution draining bin and corresponds to the tail end of the draining treatment section in an overlapped manner in the vertical direction, and the conveying direction of the secondary conveying belt is opposite to the conveying direction of the conveying belt. According to the turnover type draining device, the pickling solution draining bin in the tank body is internally provided with the secondary conveying belt which corresponds to the conveying belt in the overlapped manner in the vertical direction for reverse conveying, so that a radiator is automatically overturned and then conveyed when being conveyed and moved to the secondary conveying belt from the conveying belt, two-way rapid draining of pickling solutions at the two sides of the radiator and in a pipeline is achieved, the draining efficiency is remarkably improved, and the draining conveying stroke is shortened.

Owner:QUANJIAO SAIDELI MACHINERY

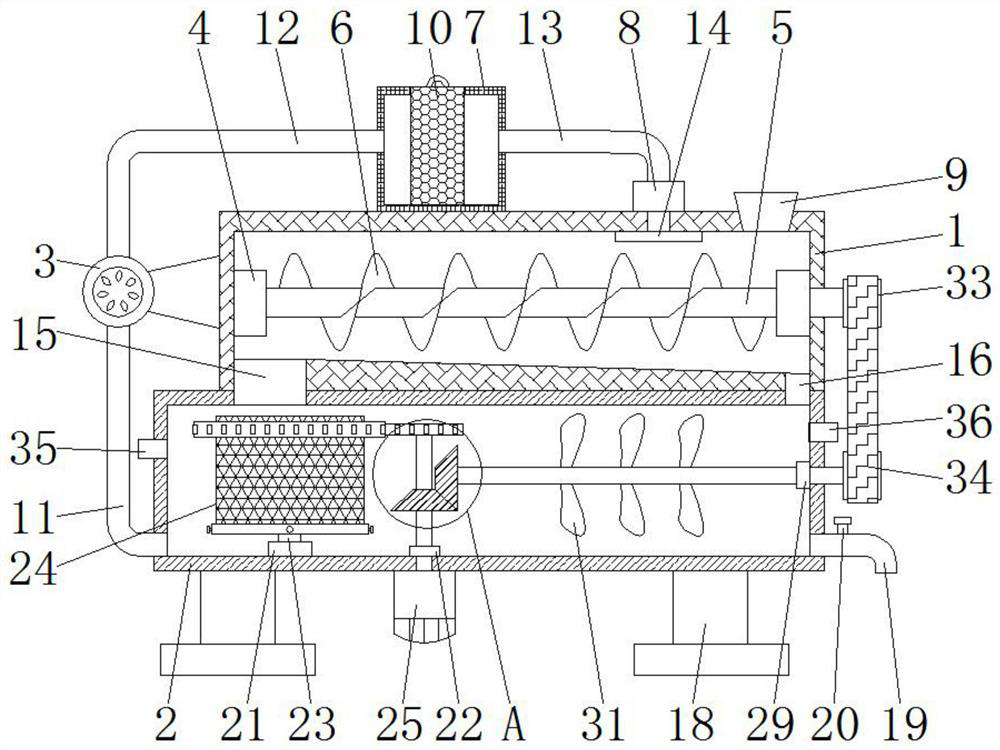

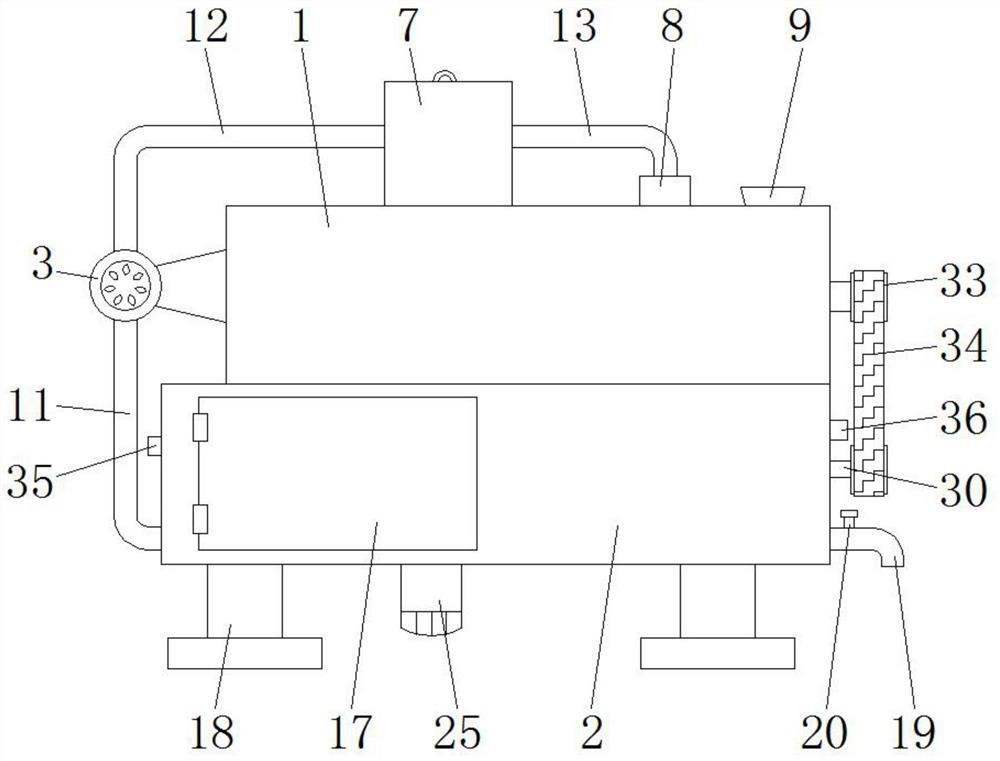

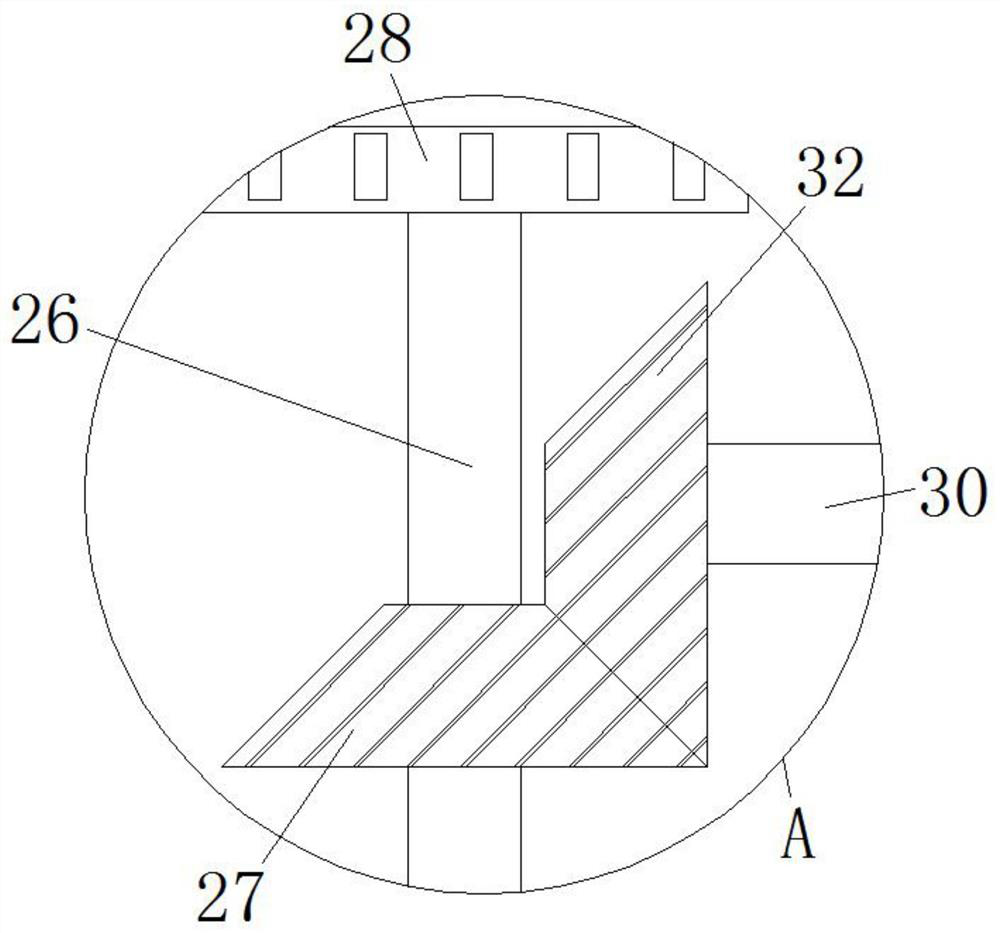

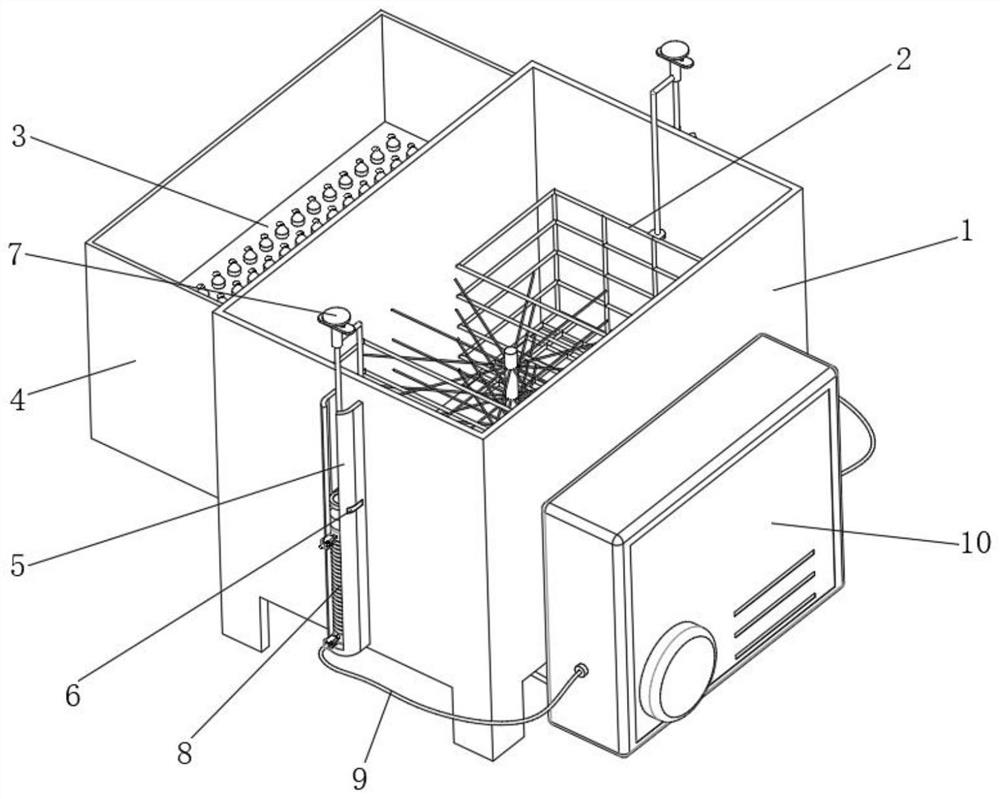

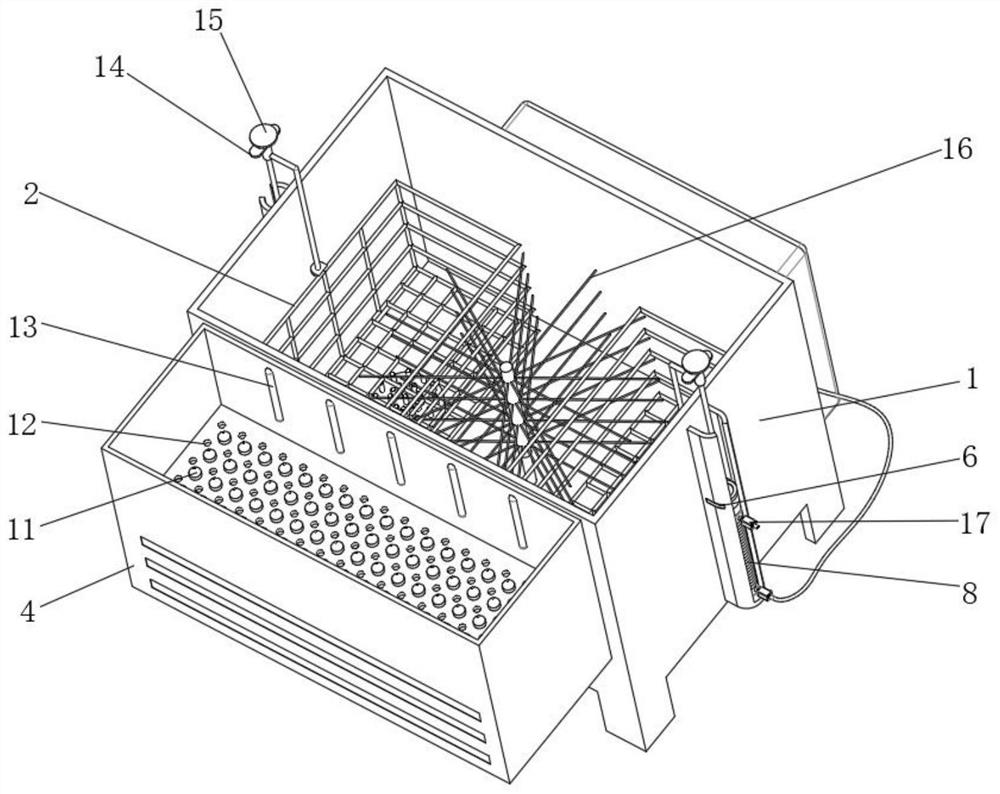

Integrated equipment for dendrobium cleaning and draining

PendingCN113319043AEasy to cleanCompact structureDrying solid materials without heatDrying gas arrangementsEnvironmental engineeringMechanical engineering

The invention discloses integrated equipment for dendrobium cleaning and draining. The integrated equipment for dendrobium cleaning and draining comprises a cleaning box and a draining box located at the bottom of the cleaning box, wherein the left side of the cleaning box is connected with a water pump through a rack, first bearing seats are fixedly installed on the inner walls of the left side and the right side of the cleaning box, and a first rotating rod is rotationally connected between the two first bearing seats; a spiral conveying blade is arranged on the outer surface of the first rotating rod, a filtering box, a pressure pump and a charging hopper are sequentially arranged at the top of the cleaning box from left to right, a filtering block is arranged in the filtering box, the bottom and the top of a water pump communicate with a water inlet pipe and a water outlet pipe separately, and the end, away from the water pump, of the water inlet pipe communicates with the bottom of the left side of the draining box; and the end, away from the water pump, of the water outlet pipe communicates with the left side of the filtering box, the right end of the filtering box communicates with a water guide pipe, and the end, away from the filtering box, of the water guide pipe communicates with the pressure pump, then extends into the right side of the cleaning box and communicates with a spray head. The integrated equipment for dendrobium cleaning and draining is compact in mechanism, capable of carrying out cleaning and draining treatment on dendrobium at the same time, and good in energy-saving effect.

Owner:安徽逸品山庄现代农业发展有限公司

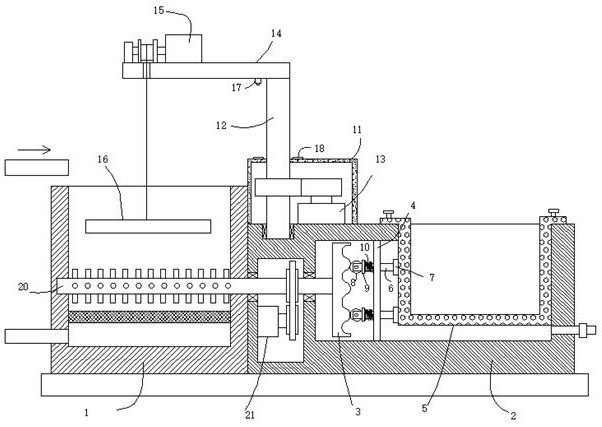

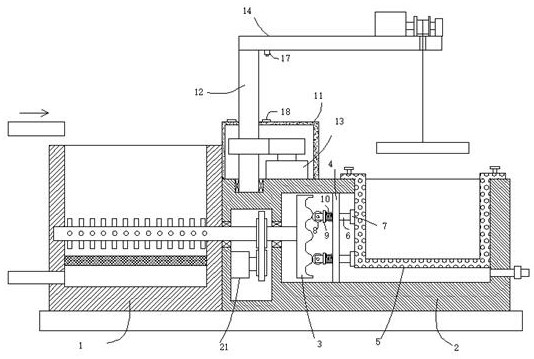

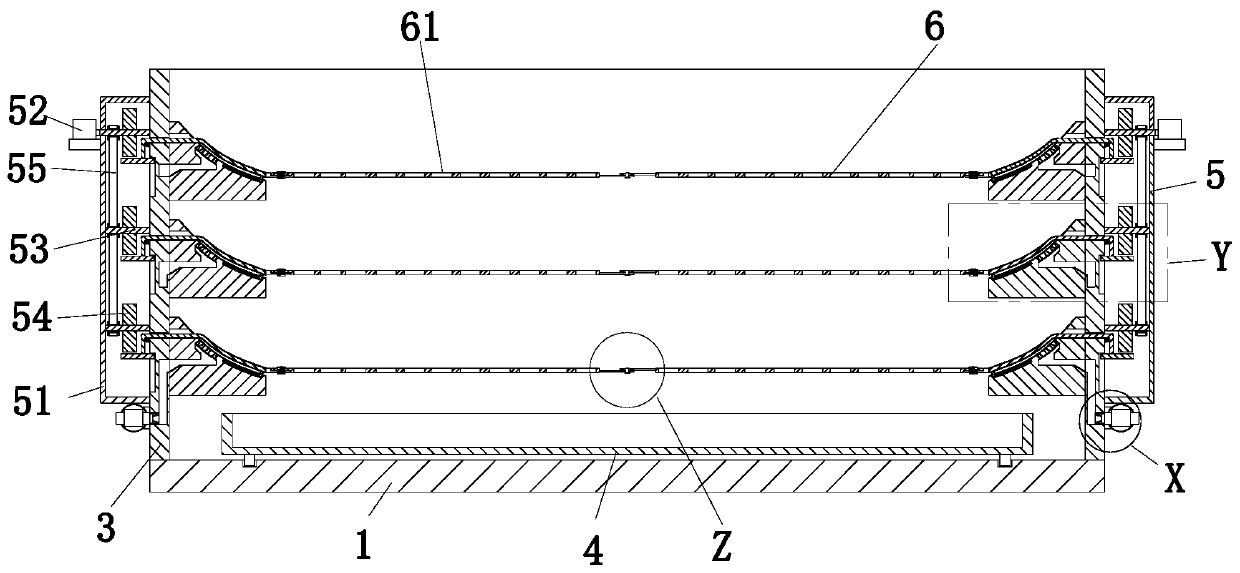

Wet chemical treatment equipment for printed circuit board

ActiveCN114222433ASmall footprintReduce labor costsPrinted circuit liquid treatmentFinal product manufactureChemical treatmentElectric machinery

The invention discloses wet chemical treatment equipment for a printed circuit board. The wet chemical treatment equipment comprises a rack, and a top cover is mounted at the top of the rack; the device further comprises a first motor, the first motor is fixed to the bottom of the rack, a guide column is sleeved with a movable column, the top of the movable column is located above the rack, a second motor is installed in the top of the movable column in an embedded mode, the protruding position of the top of a gear is sleeved with a push strip, and an adjusting plate is located in an adjusting groove. The replacement groove is formed in the bottom of the mounting plate, one end of the first clamping plate and one end of the second clamping plate are located below the mounting plate, an inner groove is formed in the edge of the bottom of the mounting plate, a movable ejector rod is connected to one side of a transverse plate through a rotating shaft, and a spoiler is connected to a cavity in the bottom of a mounting strip through a reset spring. According to the wet chemical treatment equipment for the printed circuit board, continuous operation can be carried out, occupied space is reduced, and meanwhile uniformity and efficiency are improved during deposition.

Owner:东莞塘厦裕华电路板有限公司

Agricultural product sorting and boxing device

InactiveCN109515885APerfect sorting functionImprove packaging efficiencyPackagingHydraulic cylinderReciprocating motion

The invention discloses an agricultural product sorting and boxing device. A carrying plate is included, and the upper end of the carrying plate is provided with a material barrel; the material barreland the carrying plate are fixedly connected through a supporting rod; a cover plate is in threaded connection with the upper end of the material barrel; a discharging bin is fixedly installed at thelower end of the material barrel, and is designed into a round platform type; the lower end of the discharging bin is provided with a discharging port; a hand wheel is installed at the lower end of one side of the material barrel; and a butterfly valve is installed in the discharging port, and the input end of the butterfly valve is connected with the output end of the hand wheel. According to the agricultural product sorting and boxing device, according to the characteristic of peanuts, the peanuts are placed in a water channel through a water soaking method, and the peanuts which are poor in quality and small in mass are poked to the bottom of the water channel while the peanuts are turned over through a stirring paddle; then a poking plate is driven by a guide rail cylinder to convey upper layer peanuts into a boxing mechanism; and due to linear reciprocating driving of a plug plunger hydraulic cylinder, a material receiving box is driven to move in a reciprocating manner on a slide rail, the leaching efficiency of the peanuts in the material receiving box is improved, and then the boxing efficiency is improved.

Owner:曾郁绮

Glass edge grinding machine

ActiveCN113275974AConvenient for edgingPrevent slidingEdge grinding machinesGrinding work supportsWater filterWater spray

The invention discloses a glass edge grinding machine, and belongs to the technical field of glass edge grinding. The glass edge grinding machine comprises a workbench, a water tank and a water spraying pipe, and further comprises a grinding device, a water filtering device, a fixing device, a moving device, an auxiliary device and a draining device, wherein the water tank is installed on the side wall of the workbench, and the grinding device is installed on the workbench; and one end of the water spraying pipe communicates with the water tank, the other end of the water spraying pipe extends to the grinding device, a water passing opening is formed in the top of the workbench, the water filtering device is mounted in the workbench and located below the water passing opening, the water filtering device communicates with the water tank, the moving device is mounted on the workbench, and the fixing device is slidably mounted on the moving device. The workbench is also provided with an auxiliary port, the auxiliary device is mounted on the workbench, and the draining device is mounted at the top of the workbench. According to the glass edge grinding machine, a glass plate with a sunken included angle is fixed and clamped, then the angle of a grinding point is changed according to the size of the included angle, and edge grinding is performed more closely.

Owner:LONGKOU KENUOER GLASS TECH CO LTD

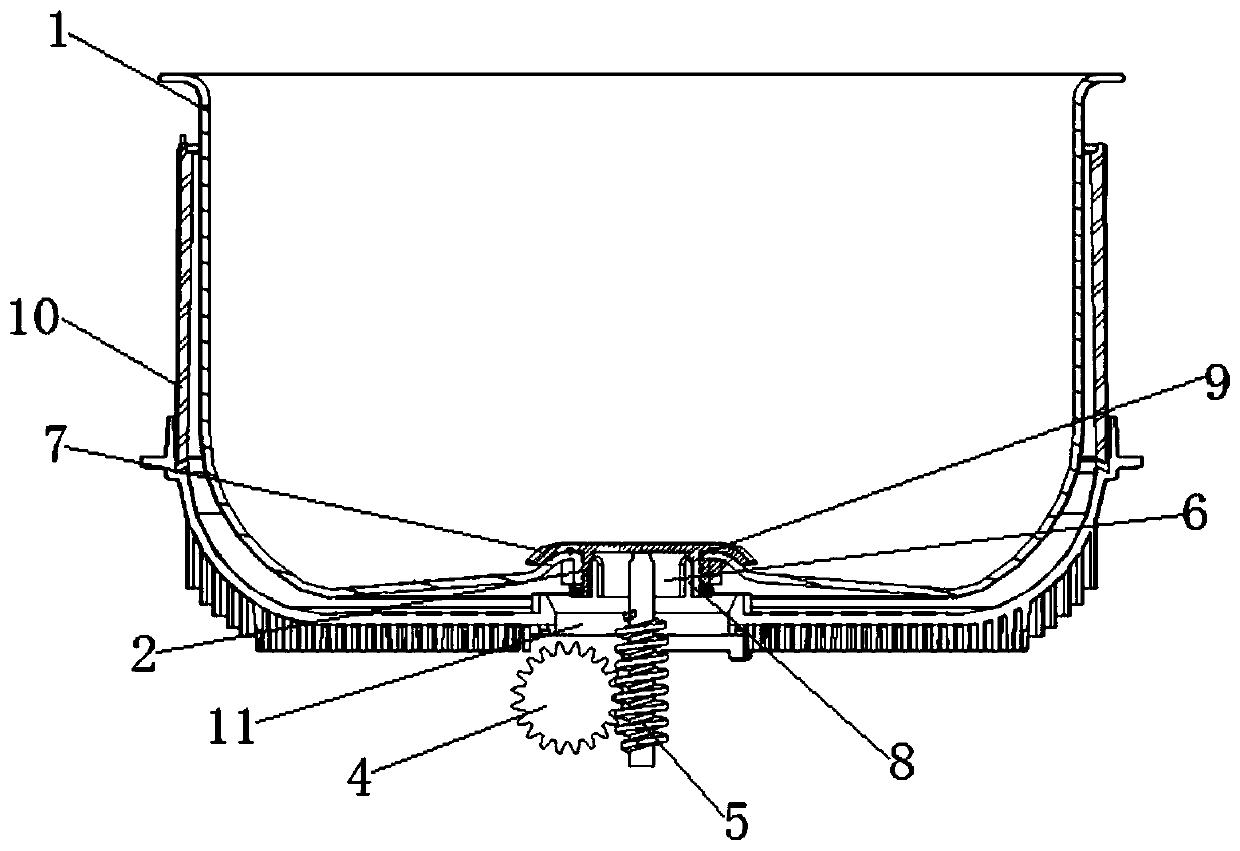

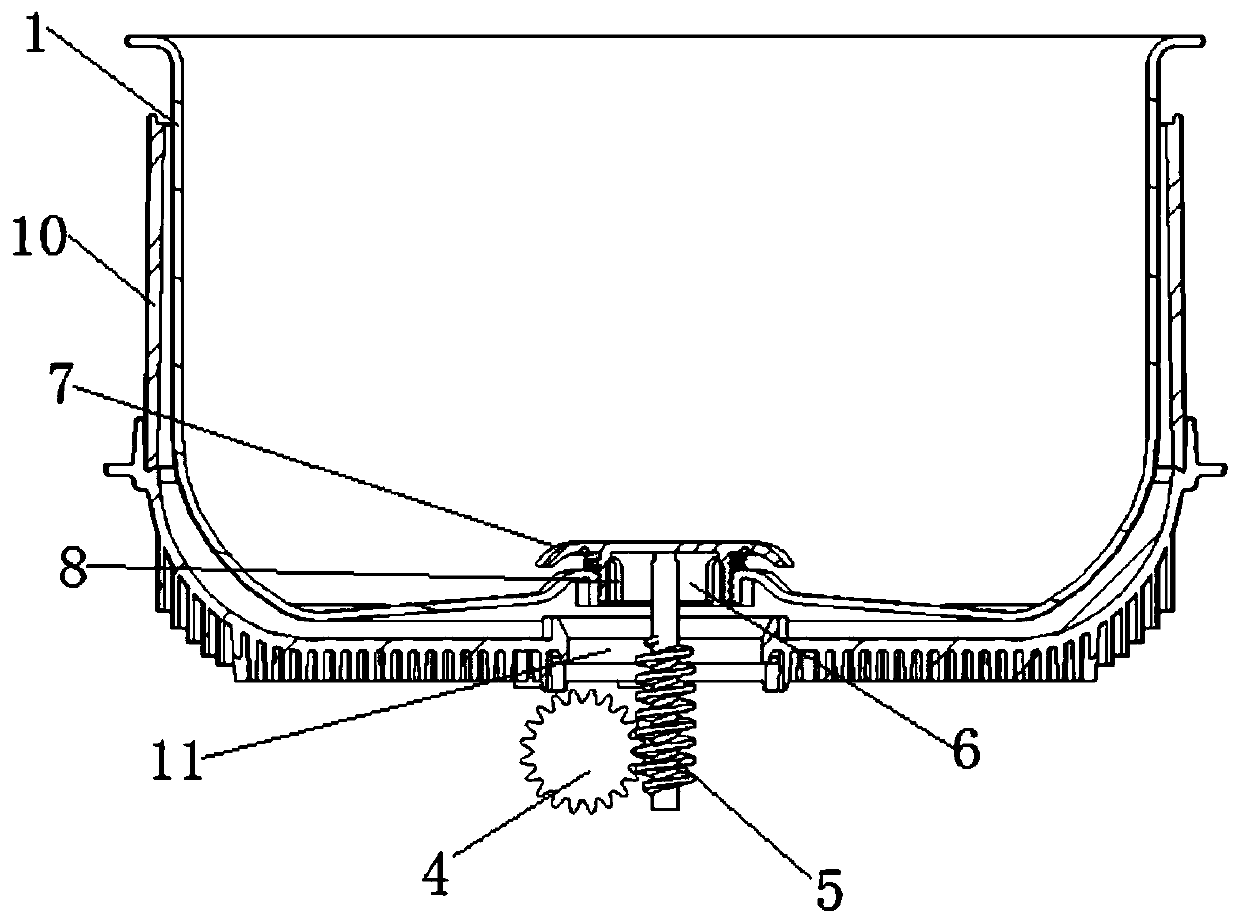

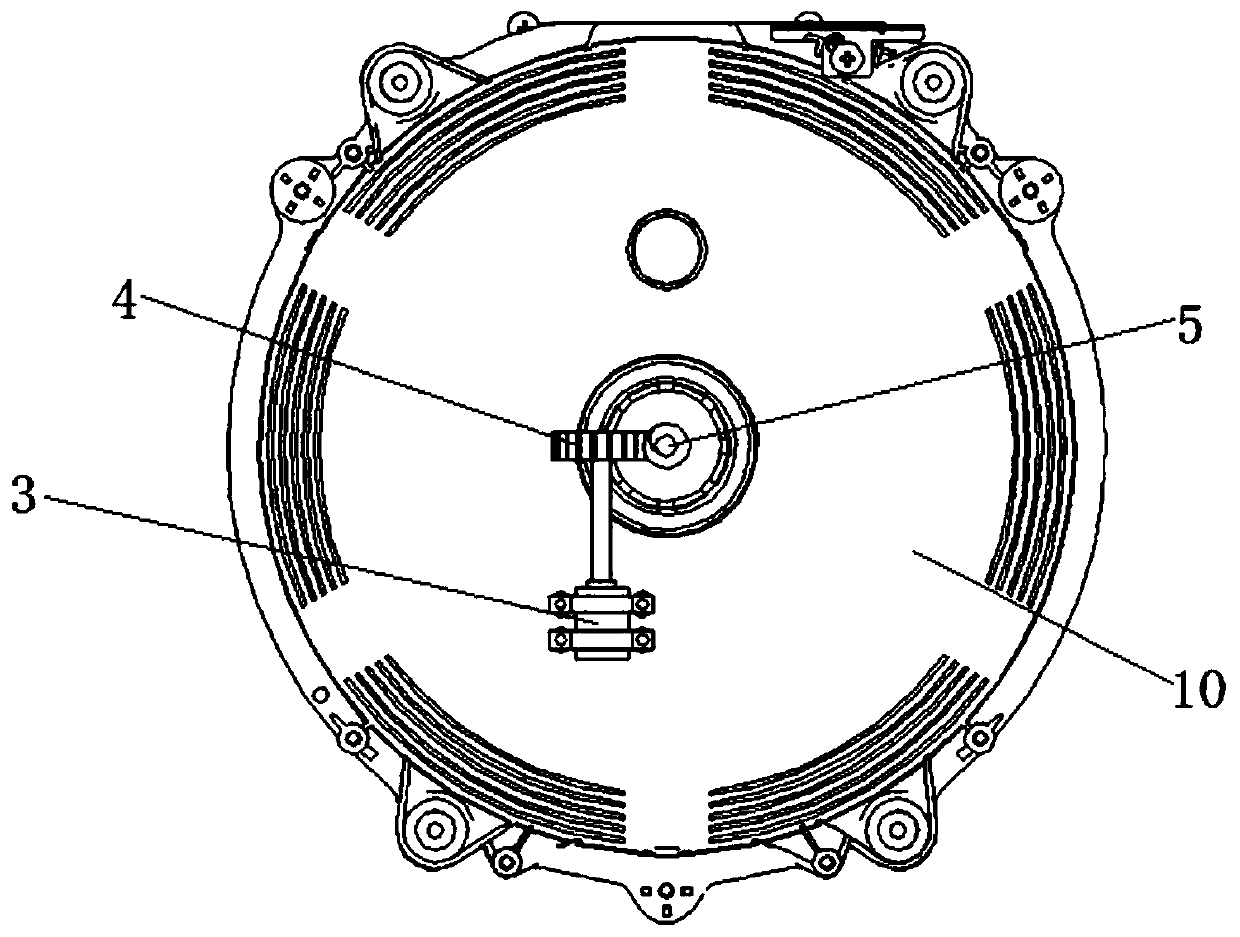

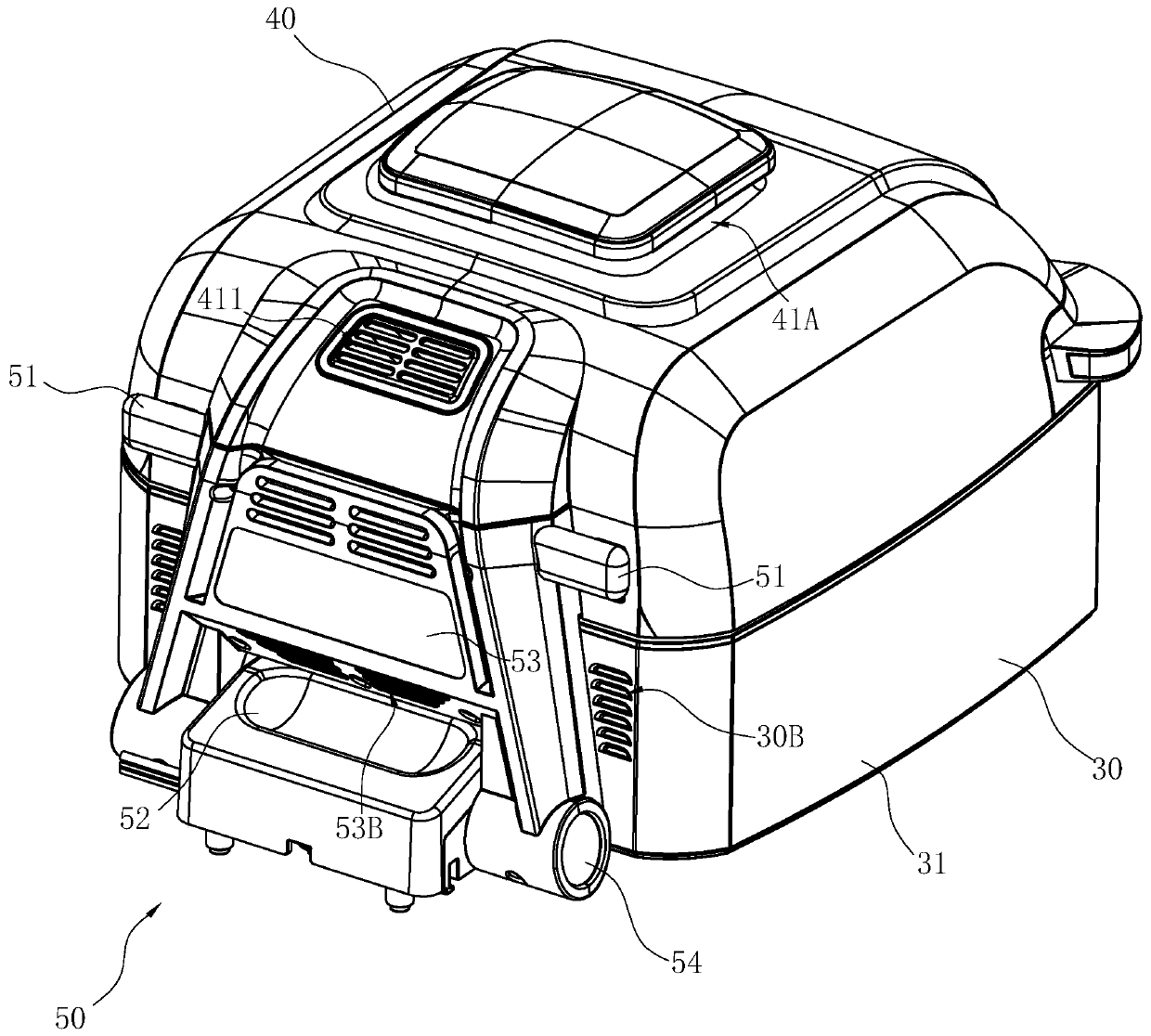

Pot body structure of cooking utensil and cooking utensil

PendingCN110840236AReduce electrical safety hazardsReduce security risksSteam cooking vesselsCooking insertsProcess engineeringEngineering

Owner:GREE ELECTRIC APPLIANCES INC

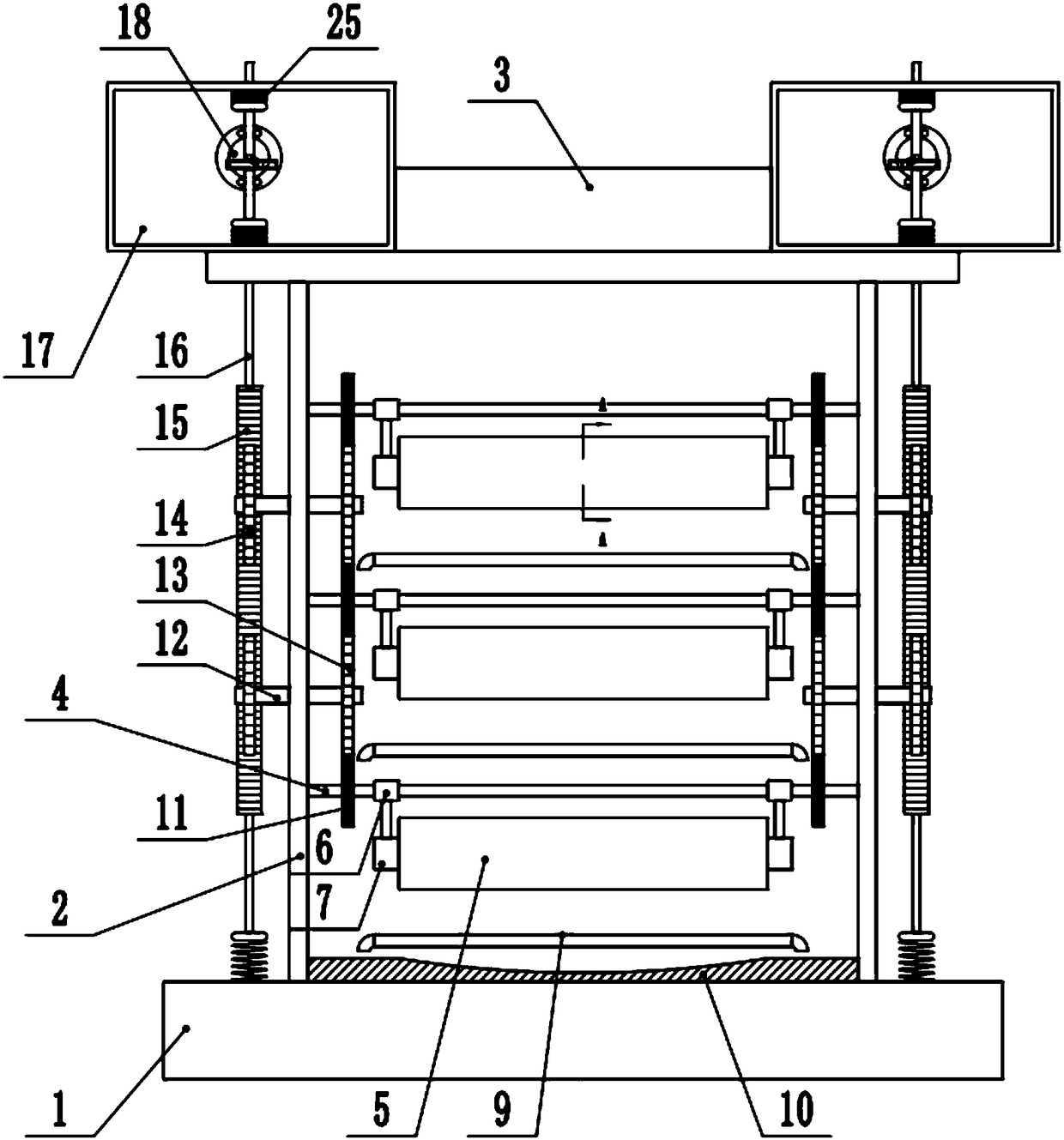

Draining machine used for salted products

The invention relates to a draining machine used for salted products. The draining machine used for salted products comprises a machine frame, and a filter plate; the filter plate is arranged on the machine frame; a water collecting drum is arranged on the machine frame; a draining drum is connected with the interior of the water collecting drum in sliding connection; the filter plate is connectedto a bottom of the draining drum in sliding connection; a press plate is connected to a top of the draining drum in sliding connection; a first magnet is fixed at a top of the press plate; a second magnet in suction with the first magnet is connected with the machine frame at a positioned above the first magnet in sliding connection; a first wedge rod is fixedly connected with a bottom of the filter plate, and counters against a second wedge rod; the second wedge rod counters against a third wedge rod at one end far away from the first wedge rod; gear teeth are fixed on the third wedge rod, and a gear is rotationally connected with the machine frame so that the third wedge rod meshes with the gear via the gear teeth; the gear further meshes with a rack, and the rack is fixedly connected with the second magnet; and a driving mechanism is fixed on the machine frame so as to drive the draining drum to slide to and fro. Compared with the prior art, draining efficiency of the draining machine used for salted products is improved for green vegetables in the draining drum are spin-dried according to the technical scheme.

Owner:重庆好弟兄食品有限公司

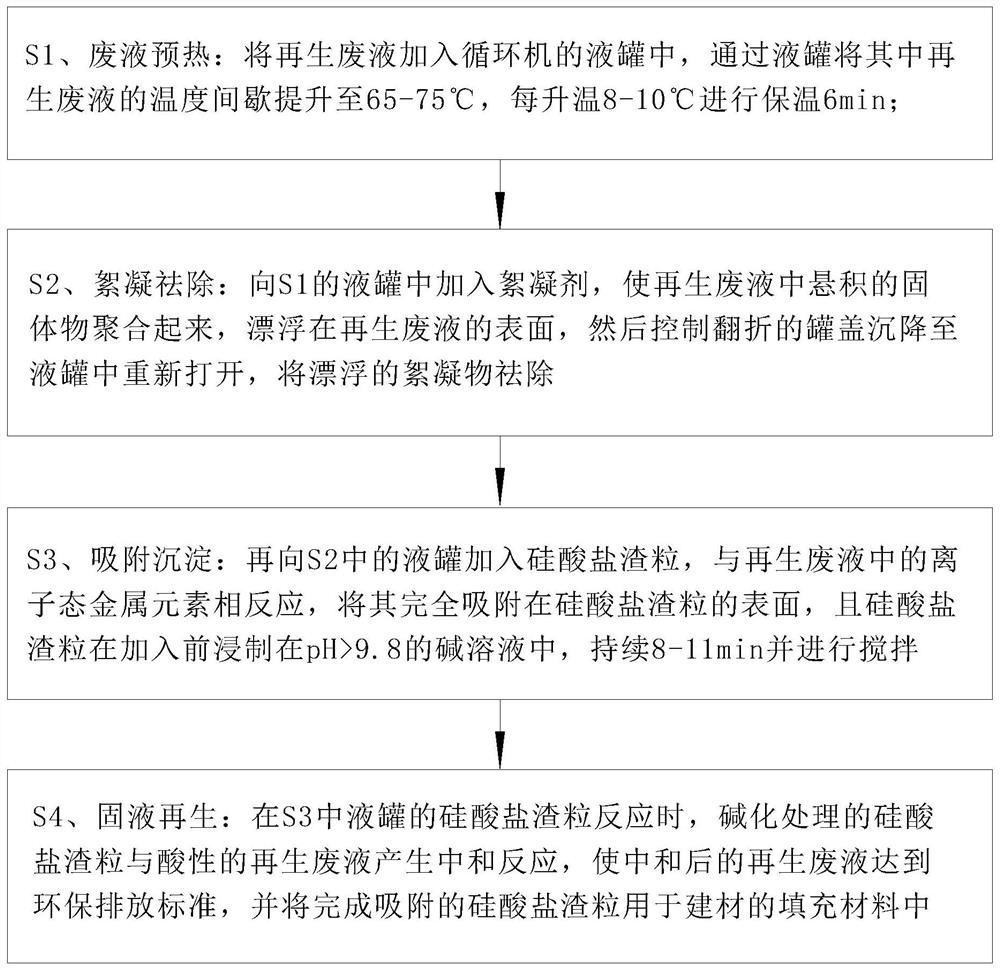

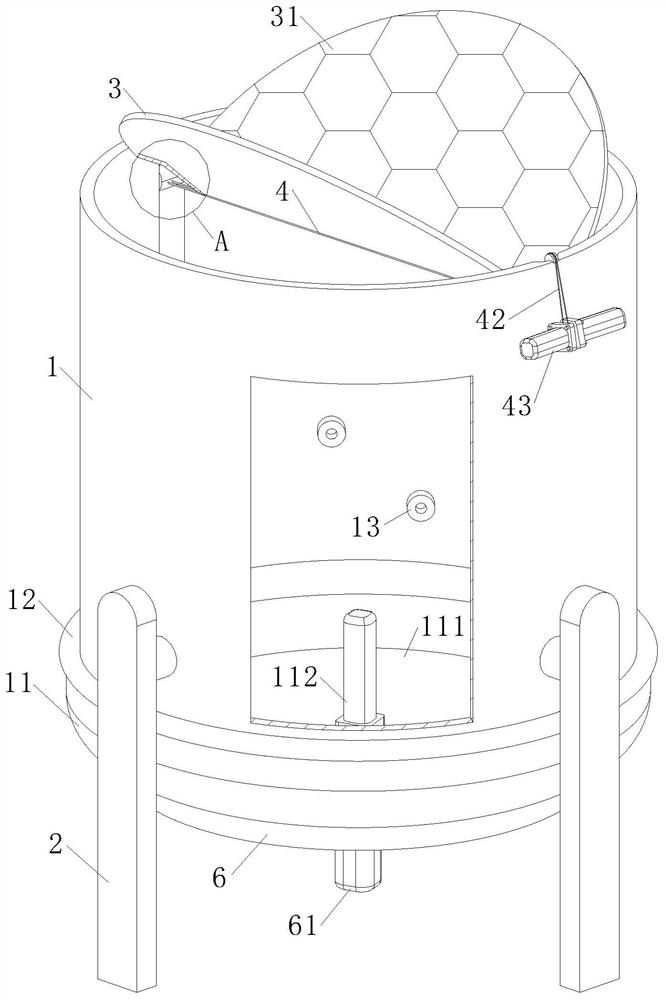

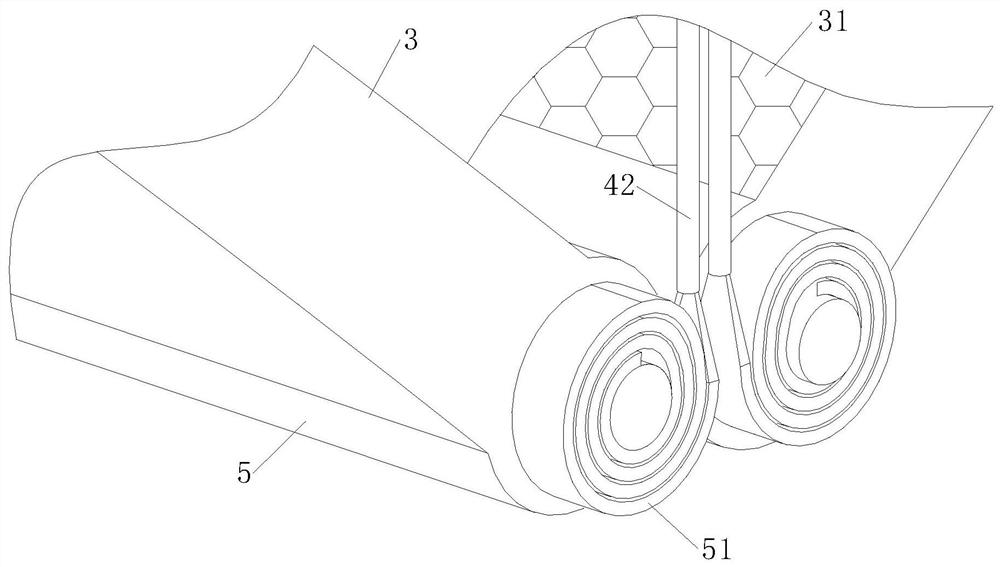

Denitration catalyst regeneration waste liquid recycling process

InactiveCN111892199AReduce erosionAvoid blind spotsSpecific water treatment objectivesTreatment involving filtrationPtru catalystEnvironmental engineering

The invention relates to the technical field of waste liquid treatment, in particular to a denitration catalyst regeneration waste liquid recycling process which comprises the steps of waste liquid preheating, flocculation removal, adsorption precipitation and solid-liquid regeneration. The circulator comprises a liquid tank, a tank rack and a controller; a pair of semicircular tank covers is arranged at the top end of the liquid tank, and a filter screen is arranged in each tank cover; when the solid suspended matters in the regenerated waste liquid are removed, the regenerated waste liquid is doped in the solid suspended matters so that the removed solid suspended matters become pollution sources, and the cyclic utilization effect of the regenerated waste liquid is reduced; therefore, the tank cover is arranged in the liquid tank, regenerated waste liquid mixed with flocculate is drained through the filter screen on the tank cover, secondary pollution caused by regenerated waste liquid in the liquid tank is avoided, the state of the regenerated waste liquid in the liquid tank is fed back through the monitor, and mixing of silicate slag particles and the regenerated waste liquid in the liquid tank is ensured in cooperation with the adjusting effect of the controller so that the application effect of the regenerated waste liquid recycling process of the denitration catalyst isimproved.

Owner:安徽远达催化剂有限公司

A draining device and method for meat processing

ActiveCN111780503BImprove draining efficiencyEasy to fixDrying solid materials without heatDrying gas arrangementsElectric machineTransmission belt

The invention discloses a draining device and a method thereof for processing meat products, comprising a bottom plate, an electric heating plate is fixedly connected to the center of the top of the bottom plate, a water collection tank is placed on the top of the electric heating plate, and the bottom plate The four corners on the left side of the top and the front and rear sides of the sump are fixedly connected with the first vertical plate, and the opposite sides of the first vertical plate are movably connected with transmission rollers, and the surfaces of the transmission rollers are connected with transmission belts . The present invention uses the first electric telescopic rod, the ultraviolet lamp tube, the second electric telescopic rod, the fan, the telescopic hose, the horizontal pipe, the air outlet pipe, the vibrating screen, the vibrating motor, the water collection tank, the buffer spring, the first motor, the rotating rod , belt pulley, squeeze roller, belt and the second motor solve the problem that the existing draining device has low draining efficiency, and it takes a long time to remove the moisture on the surface during the working process, which is very troublesome, and The problem of not being able to collect moisture.

Owner:浙江知丰食品有限公司

Draining device for aquatic product processing

ActiveCN110953842BFast inflowHigh speedDrying solid materials without heatDrying chambers/containersReciprocating motionAquatic product

The invention discloses a draining device for processing of aquatic products. The draining device comprises a rack, an outer tank body, an inner tank body and a double-cam jacking mechanism, the outertank body is located above the rack and connected with the double-cam jacking mechanism, the double-cam jacking mechanism can drive the outer tank body to move in an up-down reciprocating mode, guiderods penetrating through the rack and being in sliding fit with the rack are arranged at the bottom of the outer tank body, and load-bearing compressed springs are arranged on the parts, between therack and the outer tank body, of the guide rods in a sleeving mode; and buffer springs are arranged at the tank bottom of the outer tank body, the inner tank body is located in the outer tank body andplaced on the buffer springs, a water collecting chamber is formed in a space between the inner tank body and the outer tank body, the bottom of the water collecting chamber is connected with a drainage tube, a plurality of draining long holes are formed in the tank bottom of the inner tank body at intervals, an overhead convex ridge is arranged at the positions, on the two sides of each draininglong hole, of the tank bottom of the inner tank body, and blocking rods fixed to the tank bottom of the outer tank body are arranged in the draining long holes and are in clearance fit with the draining holes. The draining device is novel in structure, convenient to use, stable in operation, good in draining effect and high in draining efficiency.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

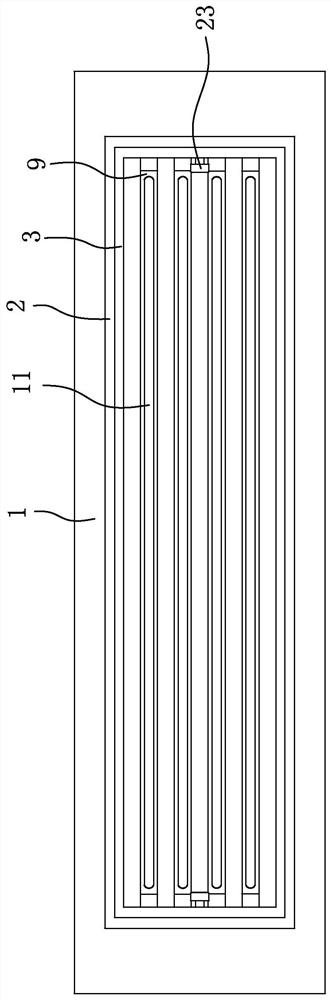

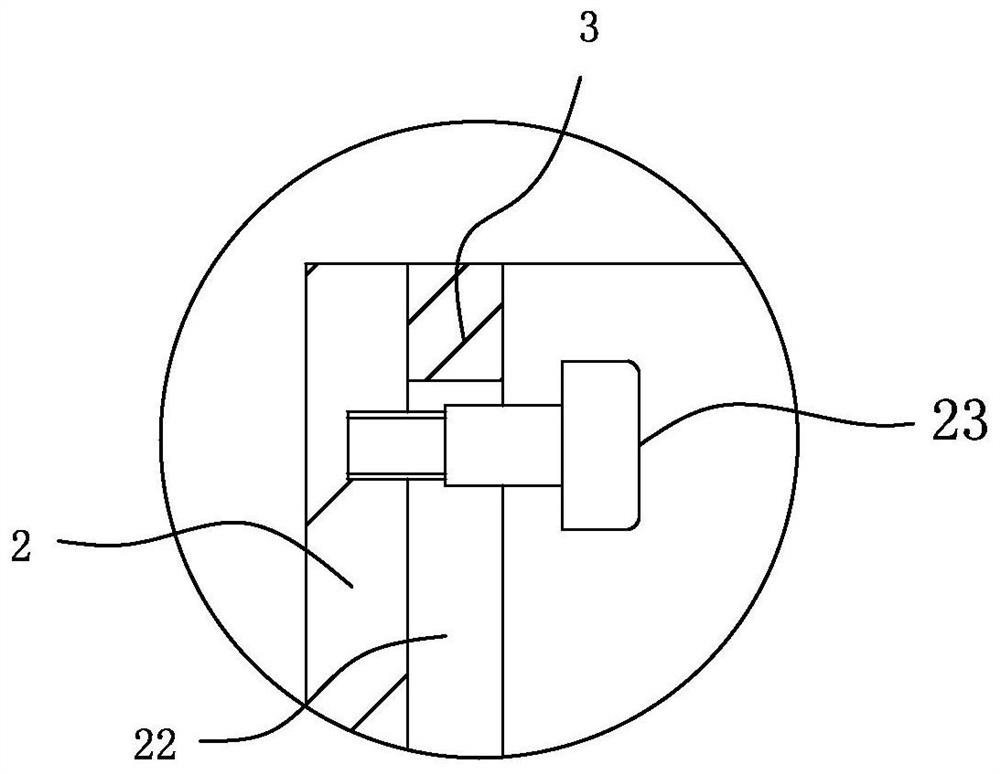

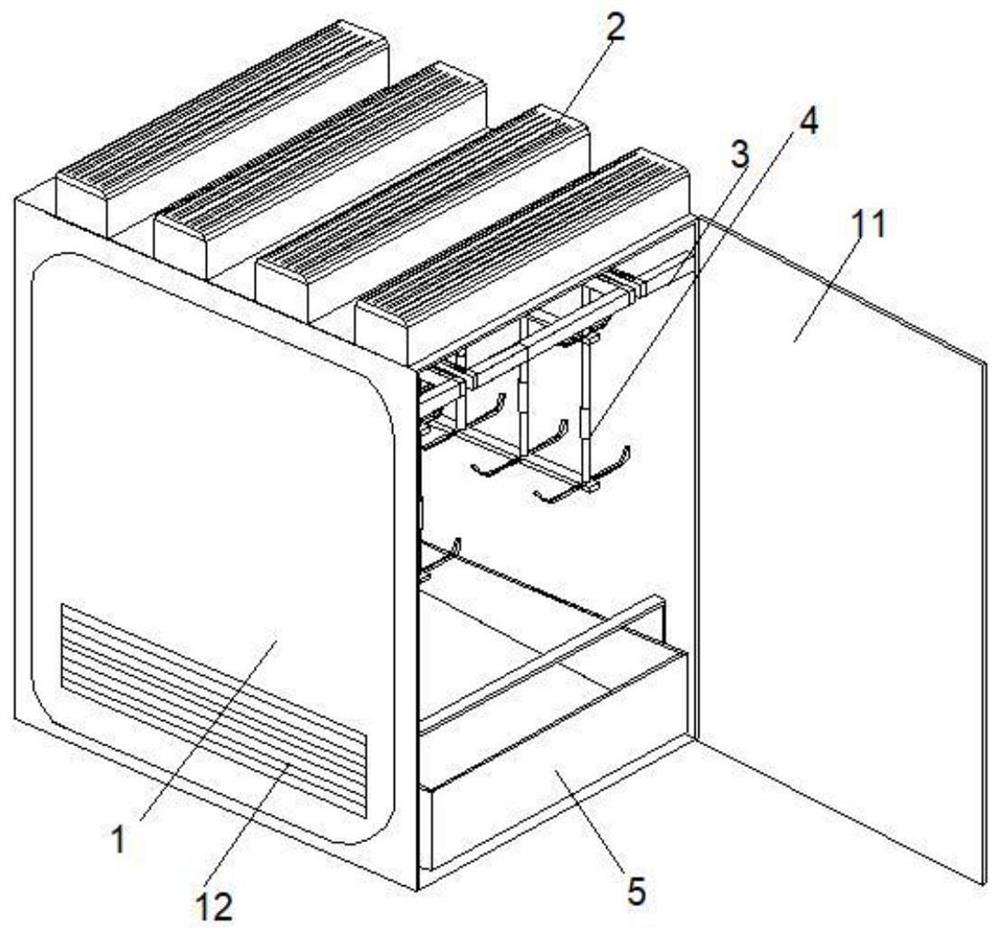

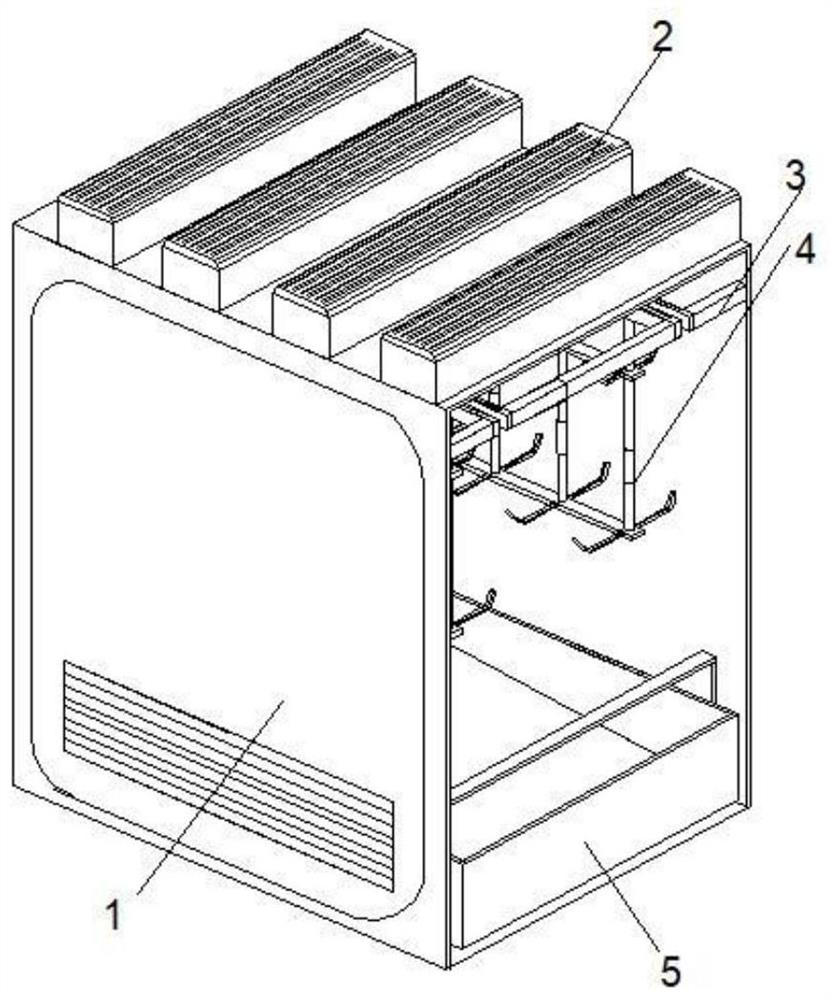

Recyclable draining device

InactiveCN113532066AEasy to recycleAvoid wastingDrying gas arrangementsDrying chambers/containersEnvironmental engineeringMechanical engineering

The invention discloses a recyclable draining device. The recyclable draining device comprises a box body of a cubic structure, a box door arranged on the front wall of the box body and a hanging frame arranged in an inner cavity of the box body, the hanging frame is arranged close to the top of the inner cavity of the box body, a draining frame is connected to the lower portion of the hanging frame, and a recycling box body is arranged below the draining frame. When the device is used, the box door is opened, the draining frame is pulled out, at the moment, a sliding plate extends outwards in the length direction of a guide rod, a goose body needing to be drained is placed on the draining frame, in the draining process, goose oil drips downwards into the recycling box body below the draining frame, and when the goose oil is collected to a certain liquid level, the recycling box body is pulled to take out the goose oil, so that the goose oil is convenient to recycle, and waste of raw materials in the draining process is avoided.

Owner:安徽清丽食品有限公司

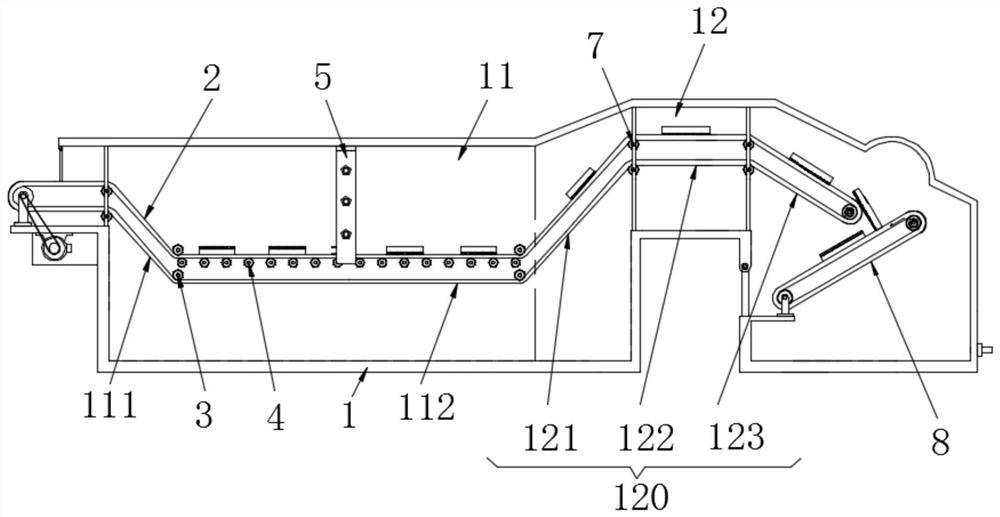

High-efficiency pickling and draining tank for radiator processing

ActiveCN112665361BShorten the conveying strokeImprove draining efficiencyDrying solid materials without heatDrying machines with progressive movementsMining engineeringConveyor belt

The invention discloses a high-efficiency pickling and draining tank for radiator processing, which relates to the technical field of radiator processing and includes a tank body and a separation and turning mechanism; a conveyor belt is arranged in the tank body, and the tank body is arranged along the conveying direction There is a pickling bin and a pickling liquid draining bin, the conveyor belt is located inside the pickling liquid draining bin and is equipped with a draining treatment section, and the inside of the pickling liquid draining bin is also provided with a secondary conveying belt, and the head end of the secondary conveyor belt corresponds up and down to the tail end of the conveyor belt. The invention realizes that the draining treatment section in the conveyor belt drives the radiator to be tilted and lifted to separate from the pickling solution and drain the pickling solution, and then the radiator is flipped and adjusted by the separation and turning mechanism and sent to the secondary conveyor belt. Drain the pickling liquid from the overturned radiator through the secondary conveyor belt, realize bidirectional fast draining of the pickling liquid on both sides of the radiator and in the pipeline, significantly improve the draining efficiency, and shorten the draining transportation journey.

Owner:QUANJIAO SAIDELI MACHINERY

An intelligent collection device for scrap metal in sewage

ActiveCN110302900BEasy to absorbEasy to drainMagnetic separationStationary filtering element filtersWater filterSewage

The invention discloses an intelligent collecting device for waste metal in sewage, and relates to the field of collecting devices. The intelligent collecting device comprises a filtering box and a water filtering box. The inner chamber of the water filtering box is divided into a water filtering chamber and a mounting chamber. A mounting cover is arranged at the top of the water filtering box. Anopening communicated with the water filtering chamber is arranged at the top of the water filtering box, and a collecting box is arranged in the opening. Water leakage holes are uniformly distributedin the outer side of the collecting box. A horizontal rotating crossbar is rotatably arranged in the filtering box. A loose stock column is fixed along the length of the rotating crossbar. A filter net fixed in the filtering box is arranged below the loose stock column. The right end of the crossbar passes through the mounting chamber and extends into the water filtering chamber. According to theinvention, metal in sewage can be collected, and collected metal can be drained; materials accumulated on the filter net can be flipped to facilitate the absorption of an electromagnet; and metal inthe collecting box is periodically vibrated for easy draining.

Owner:盐城市远大环保设备有限公司

Pickling flip-type draining device for radiator processing

ActiveCN112629227BAchieve two-way fast drainingImprove draining efficiencyConveyorsDrying chambers/containersEngineeringConveyor belt

The invention discloses a pickling flip-type draining device for radiator processing, relates to the technical field of radiator processing, and comprises a tank body and a secondary conveyor belt; a conveyor belt is arranged in the tank body, and a conveyor belt is arranged in the tank body along the conveying direction. A pickling bin and a pickling liquid draining bin, the conveyor belt is located inside the pickling liquid draining bin and is equipped with a draining treatment section; the secondary conveyor belt is set inside the pickling liquid draining bin and is connected with the draining processing section. The tail ends of the sections overlap in the vertical direction, and the conveying direction of the secondary conveyor belt is opposite to that of the conveyor belt. In the present invention, a secondary conveyor belt corresponding to the vertical overlap of the conveyor belt is arranged in the pickling liquid draining bin inside the tank to cooperate with the transmission, so that the radiator is transported from the conveyor belt to the secondary conveyor belt Automatically turn over and then transport, realize two-way fast draining of the pickling liquid on both sides of the radiator and in the pipeline, significantly improve the draining efficiency, and shorten the draining and conveying journey.

Owner:QUANJIAO SAIDELI MACHINERY

Neurosurgical instrument cleaning equipment and use method thereof

InactiveCN114101183AEasy to take outScrub fullyCleaning using toolsCleaning using liquidsSurgical instrumentationExhaust valve

The invention discloses neurosurgical instrument cleaning equipment and a use method thereof, and relates to the technical field of neurosurgical instrument cleaning equipment. The use convenience is improved; the device specifically comprises a cleaning box, a placement basket is in lap joint in the cleaning box, a first connecting rod is arranged on the side wall of the top of the placement basket, and an operation part is arranged at one end of the first connecting rod; a brushing mechanism is arranged in the cleaning box; the placing baskets are symmetrically arranged relative to the brushing mechanism; a second connecting rod is fixed at the bottom of the operating part; the method comprises the following steps that a user puts a to-be-cleaned medical instrument into a placing basket; when the pressing handle is pressed, a circuit between the two second conducting strips is conducted, and the exhaust valve is opened. According to the medical instrument cleaning device, by arranging the placement basket, the brushing mechanism and other structures, to-be-cleaned medical instruments can be placed in the placement basket, the placement basket is placed in the cleaning box, cleaning liquid is injected into the cleaning box, and the brushing mechanism is controlled to brush the instruments in the placement basket.

Owner:夏涛

Energy-saving domestic wastewater treatment device capable of preventing pipeline blockage

The invention discloses an energy-saving domestic wastewater treatment device capable of preventing pipeline blockage. The device includes a working chamber, a launching mechanism arranged at that topof the working chamber, a drain pipe arranged at the bottom of the working chamber and a crushing mechanism horizontally arranged on the inner wall of the working chamber. The inner wall of the working chamber is also symmetrically provided with a first casing and a second casing, the second casing moving horizontally in a reciprocating manner with respect to the first casing, and the first casing and the second casing surrounding the crushing mechanism and forming the crushing chamber when the second casing approaches the first casing until the openings of the first casing and the second casing contact each other. The invention can effectively prevent blockage of pipes, pools or sinks, meanwhile realizing waste water reuse, energy saving and environmental protection.

Owner:HEFEI HUIZHI NEW MACHINERY TECH CO LTD

Draining device for preparing pickled Chinese cabbages

PendingCN110522053AImprove draining efficiencyFast dryingFood treatmentDrain efficiencyMechanical engineering

The invention discloses a draining device for preparing pickled Chinese cabbages. The device comprises a drying mechanism, a workbench and a controller, a vibration mechanism is arranged above the workbench, a material overturning mechanism is arranged above the vibration mechanism, and the material overturning mechanism comprises a support, a sliding rail and a sliding table. The sliding rail isinstalled on the inner side of the support, the sliding table is arranged on the sliding rail, the rotation wheels are installed in the sliding table, a motor is installed on the front portion of thesliding table, an electric telescopic column is installed below the sliding table, a material overturning frame is installed below the electric telescopic column, and the motor and the electric telescopic column are electrically connected with the controller. The draining device is simple in structure, convenient to operate and low in production cost, the material draining efficiency is greatly improved, and meanwhile the material drying speed is increased.

Owner:HEZHOU UNIV

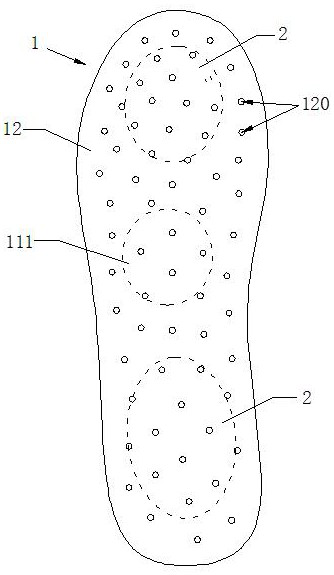

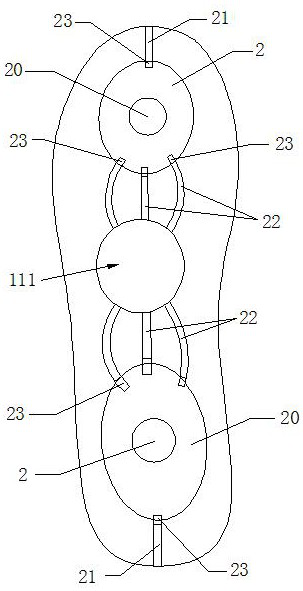

Blowing dehumidification breathable sole

The invention relates to an air-blowing dehumidification breathable sole which comprises a sole base and a sole plate stacked on the sole base, a groove is formed in the middle of the upper end of the sole base, a plurality of drainage grooves are distributed around the groove, the drainage grooves obliquely extend downwards from the shoe edge to be communicated with the groove, and a plurality of draining holes are formed in the bottom of the groove. Containing cavities are formed in the foot sole portion and the heel portion of the shoe sole base, air bags are installed in the containing cavities, and each air bag is provided with an air inlet pipe communicated with the outside and a plurality of exhaust pipes communicated with the grooves. According to the breathable shoe, the groove is formed in the middle of the upper end of the sole base, the drainage grooves are distributed around the groove, the air bags are arranged in the foot sole part and the heel part of the sole base, the air bags of the foot sole part and the air bags of the heel part blow air to the groove alternately, and blown air flow is aligned to the sole plate along the drainage grooves for dehumidification; the double air bags blow air alternately, so that air in the shoe sole flows fast, the draining efficiency is high, and the blowing dehumidification effect is good.

Owner:晋江市火乐果体育用品有限公司

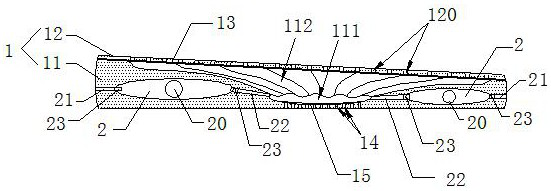

Method for treating natural stone sand as stone-like paint preparation raw material

The invention provides a method for treating natural stone sand as a stone-like paint preparation raw material. Operation is completed through cooperation of a bottom plate, two connecting plates, twohanging plate groups, a collection frame, two driving devices and a draining net group. By adopting the method, the problems that in a conventional draining mode, generally stone sand which is washedwith water is put into a container with a screening net and is subjected to natural drip-dry, however, in the drip-dry process, contact surfaces of adjacent stone sand cannot be dried within a shorttime, water droplets dropped from stone sand above a stone sand layer can pass a stone sand surface below, then stone sand on the lower side of the stone sand layer can be in long-term contact with water droplets and thus partial corrosion can be caused, in addition, in the conventional draining mode, the upper part of the stone sand layer is firstly drip-dried and the lower part is dried later, and the like, can be solved.

Owner:JIANGXI LONGZHENG SCI & TECH DEV

A printed circuit board wet chemical processing equipment

ActiveCN114222433BSmall footprintReduce labor costsPrinted circuit liquid treatmentFinal product manufactureElectric machineryStructural engineering

Owner:东莞塘厦裕华电路板有限公司

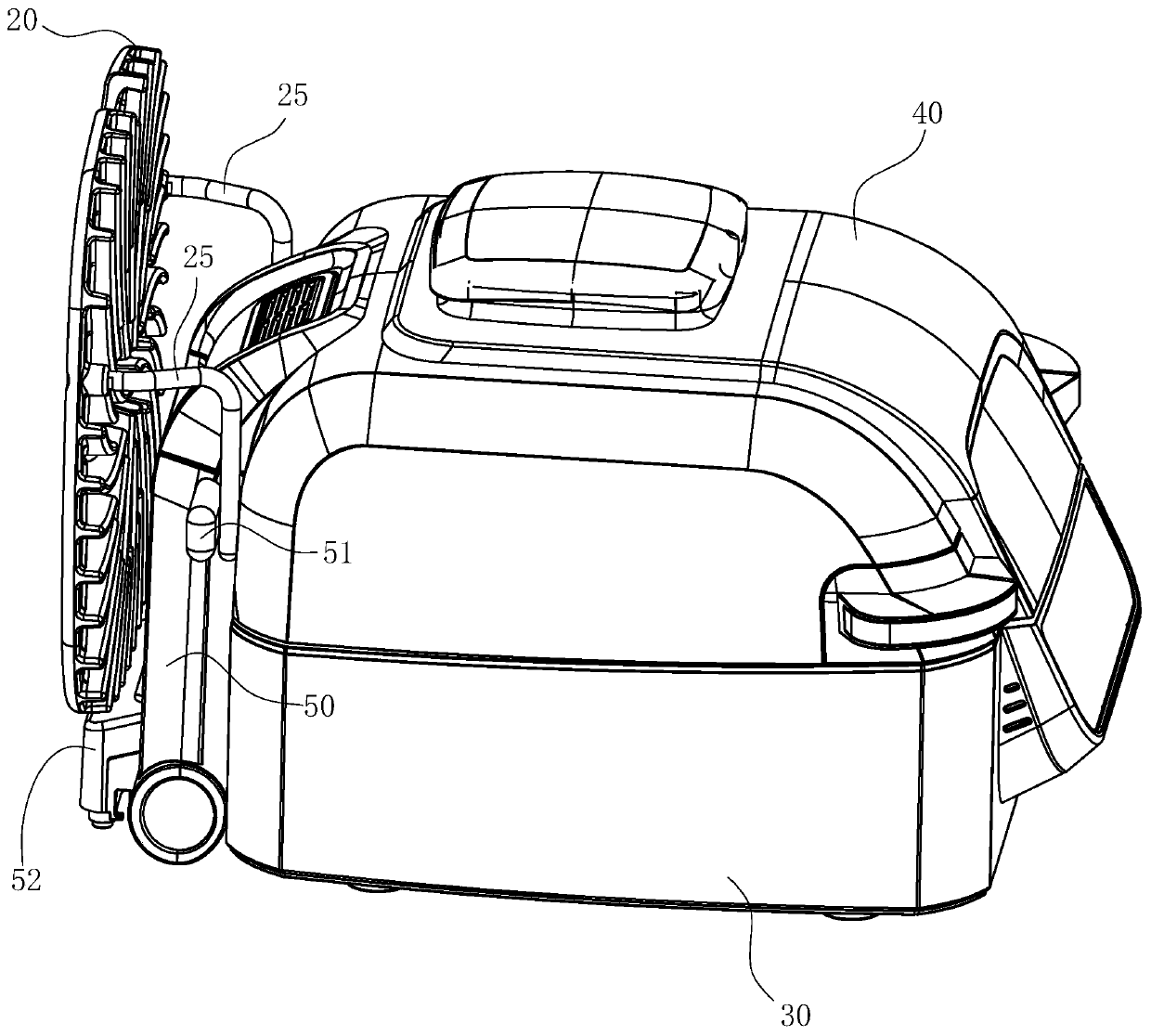

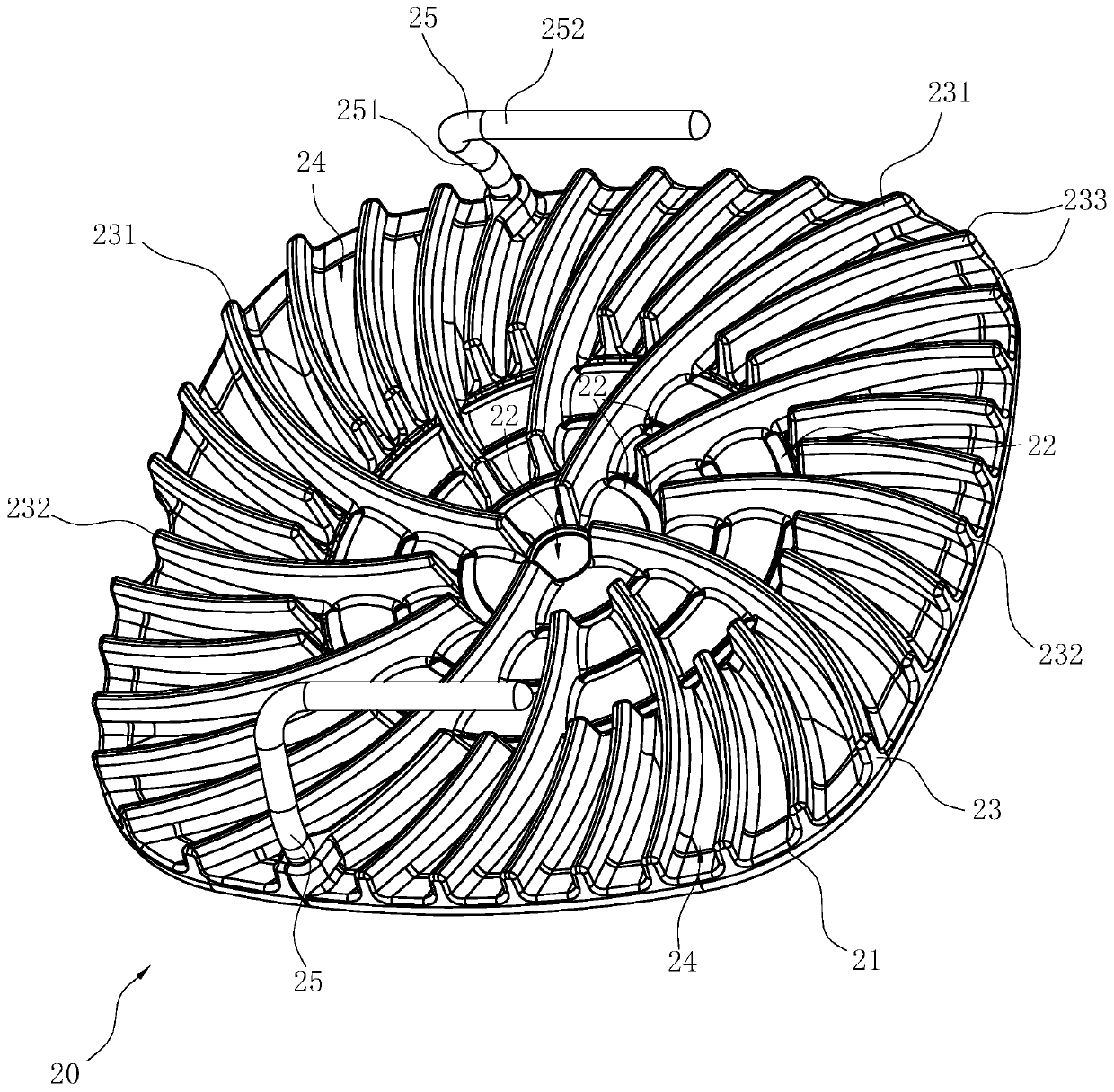

Air fryer

PendingCN110123158ARealize storageImprove hygieneBaking vesselsRoasters/grillsMechanical engineeringSanitation

The invention relates to an air fryer which comprises a base, a fryer body (10) arranged in the base, a hot air device arranged in the base and used for generating hot air, a baking tray (20) arrangedin the fryer body (10). The air fryer is characterized in that a lifting handle (25) is arranged on the baking tray (20), and a support (51) capable of supporting the lifting handle (25) to enable the baking tray (20) to stand vertically is arranged at the upper portion of the base. Compared with the prior art, the air fryer can support the baking tray after cooking, so that oil draining of the baking tray is achieved, and use sanitation is improved.

Owner:YUEDA ELECTRONICS TECH

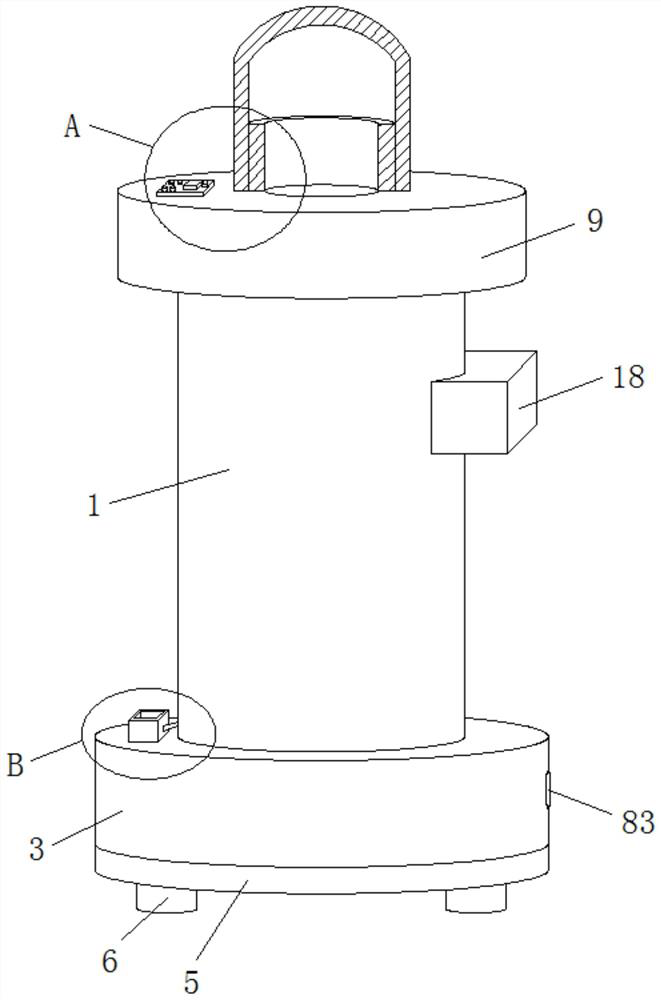

One-button intelligent automatic drying equipment and operation method for umbrellas

ActiveCN111879090BReduce labor intensityImprove experienceDrying solid materials without heatDrying chambers/containersControl engineeringStructural engineering

The invention belongs to the technical field of smart home furnishing, in particular to a one-button intelligent automatic drying equipment for umbrellas and an operation method, including a housing, a self-cleaning layer is fixedly bonded inside the housing, and a fixed block is fixedly connected to the lower surface of the housing , the lower surface of the fixed block is fixed with a counterweight, the lower surface of the counterweight and the lower surface of the fixed block are on the same level, the lower surface of the fixed block is fixedly connected with a rubber shock pad, and the lower surface of the fixed block is fixed Symmetrically distributed support legs are connected, and the lower surfaces of the two support legs penetrate and extend to the lower surface of the rubber shock absorbing pad. The umbrella one-button intelligent automatic drying equipment and operation method achieve the centrifugal force generated by the rotation of the umbrella placement frame through the mechanism to perform uniform centrifugal drying on the multiple umbrella surfaces of the umbrella in the plurality of placement holes of the umbrella placement frame, which is more efficient than the existing The draining method has high draining efficiency and short draining time, which has the effect of reducing the labor intensity of the user and improving the user experience.

Owner:广东众科智能科技股份有限公司

A kind of bridge accessories processing equipment

ActiveCN114192488BIncrease the form of exerciseQuality improvementPretreated surfacesScrew-threads articlesStructural engineeringMechanical engineering

The invention relates to the technical field of bridge fittings processing, and discloses a bridge fittings processing equipment, which includes a rotating frame and a centralized processing cage. The centralized processing cage is composed of a shield and a base that is clamped and fixed at the lower end of the shield. The shield and the base The surface of the socket is provided with a number of holes; the middle part of the base is provided with a circular recess, and a plurality of workpiece positions are arranged around the recess ring on the base. The screw parts to be processed; each opening is provided with a coil assembly, and the screw parts to be processed are inserted into the inner side of the coil assembly; the bottoms of the degreasing soaking tank, the coating liquid soaking tank and the draining tank are all provided with a reciprocating drive mechanism; the equipment, Integrate and optimize multiple processing equipment for anti-corrosion processing of screw parts, the equipment is more integrated, the volume is small, and the processing efficiency and effect are improved.

Owner:江苏月生达机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com