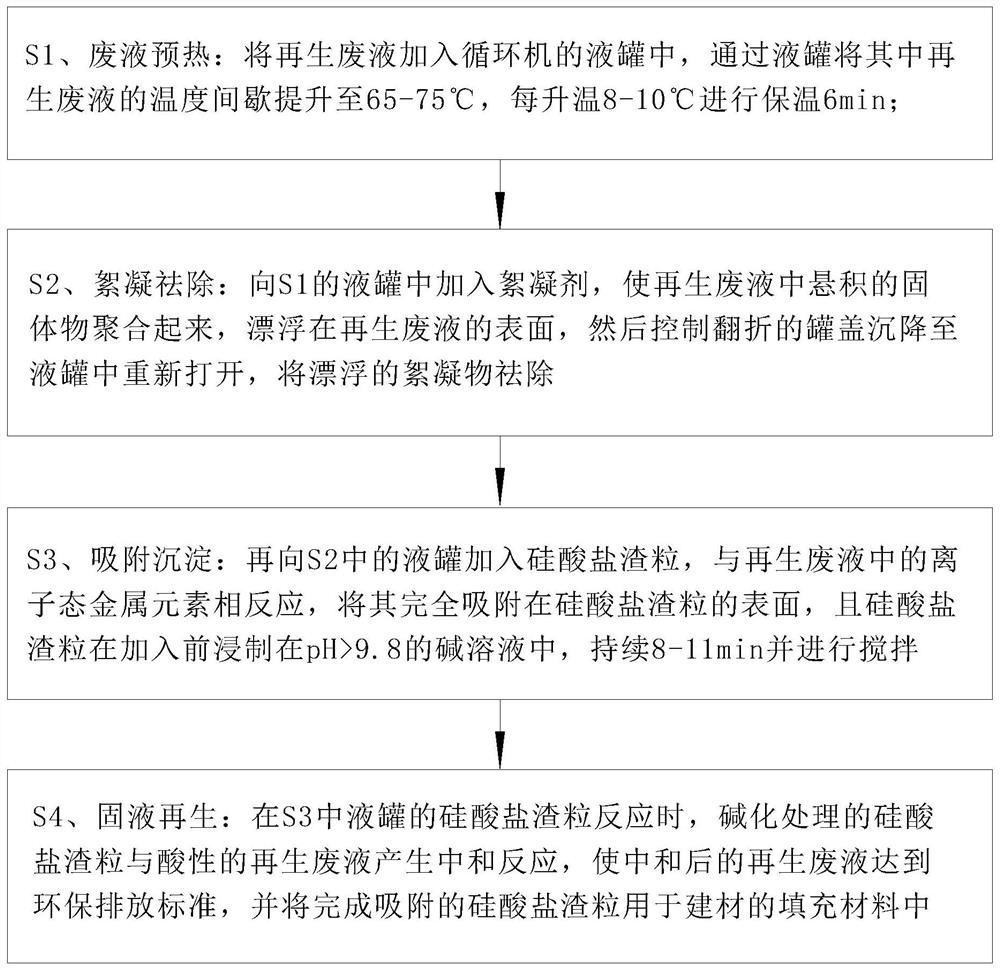

Denitration catalyst regeneration waste liquid recycling process

A denitration catalyst and technology for regenerating waste liquid, applied in chemical instruments and methods, special treatment targets, water/sludge/sewage treatment, etc. Secondary pollution and other problems, to achieve the effect of reducing erosion, avoiding secondary pollution and slowing fluid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

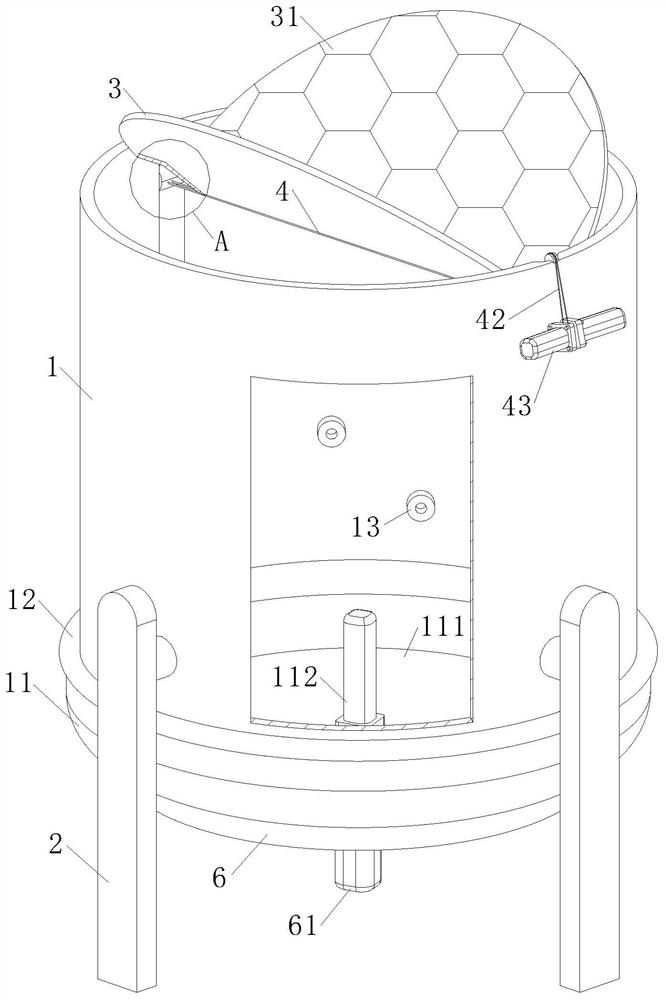

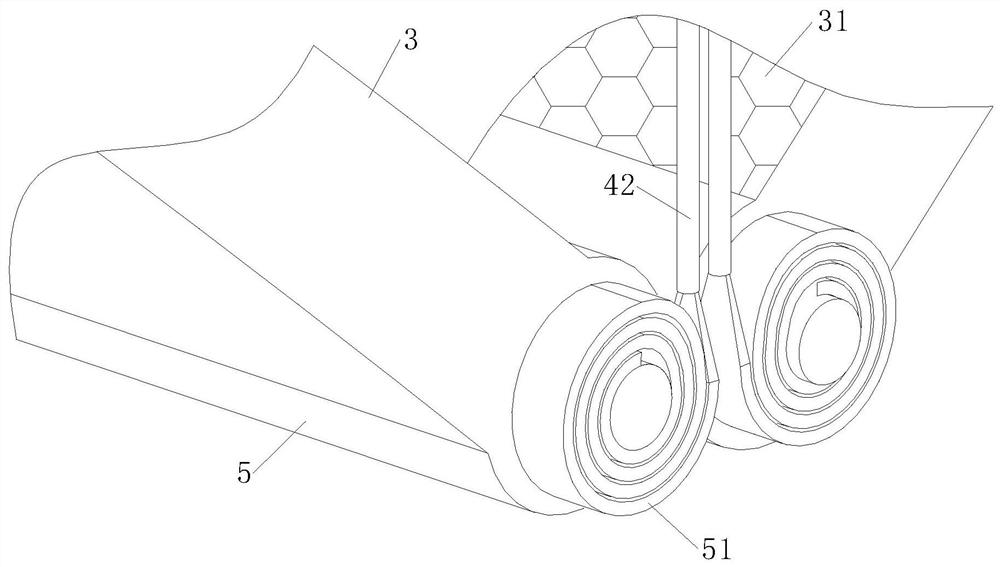

[0036] As an embodiment of the present invention, the rotating shaft 4 includes a pair of engaged shaft rods 5, the shaft rods 5 maintain a symmetrical posture between the can lids 3, and the ends of the shaft rods 5 are rotatably installed in the limit block 41; During the lifting process of the liquid tank 1, the tank cover 3 collects the suspended flocs on its surface and maintains them on the top of the liquid tank 1, and drains the regeneration waste liquid mixed in the flocs into the liquid tank 1, which requires a tank The cover 3 unfolds from a folded state to a flat state after being immersed in the regeneration waste liquid; through a pair of engaged shaft rods 5 arranged in the rotating shaft 4, the tank covers 3 are in a symmetrical opening and closing state, and the tank cover 3 is initially at a sharp point. In the open state of the part facing downwards, the adjustment line 42 only controls the lifting process of the tank cover 3 through the limit block 41. After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com