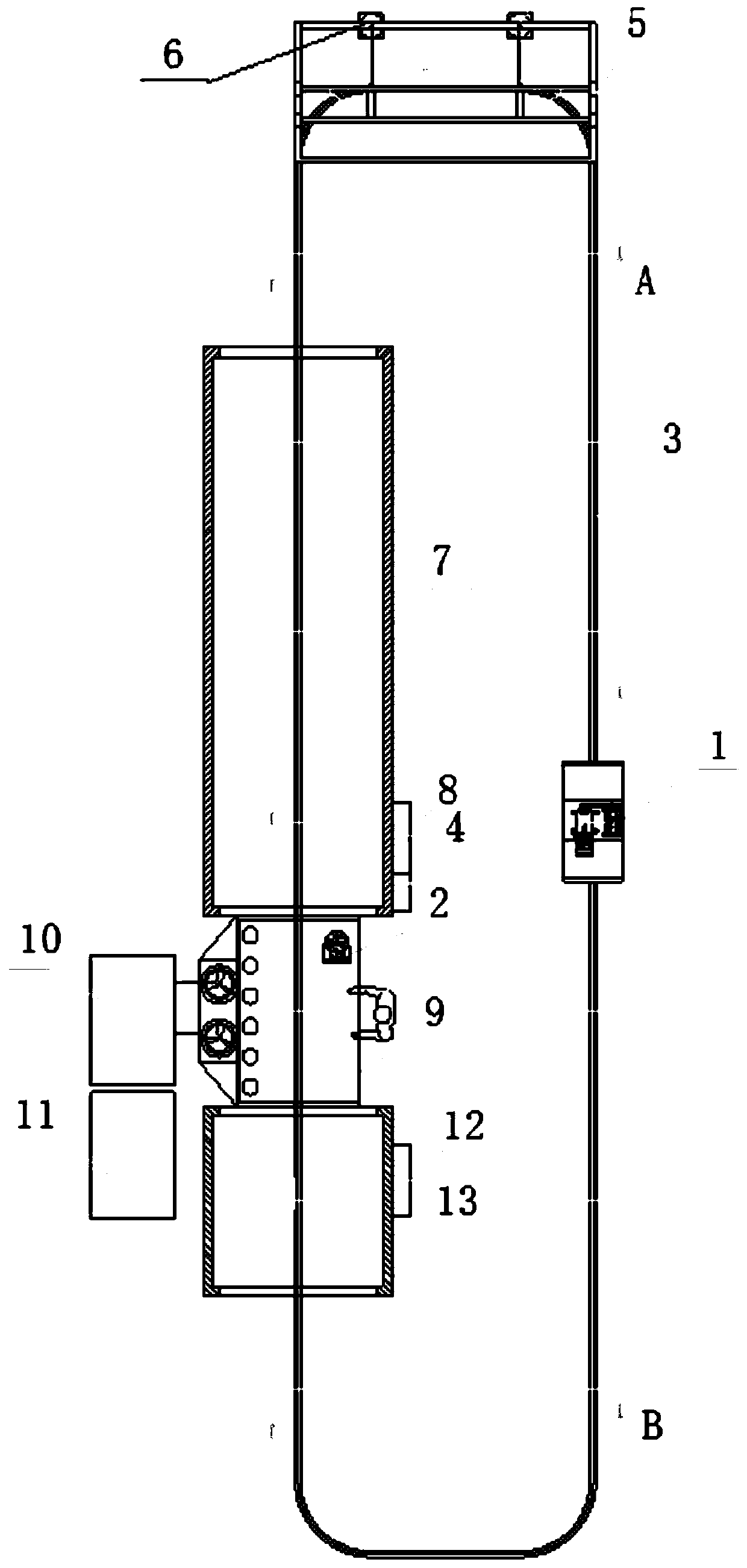

Stepping type epoxy powder electrostatic spraying production line for nodular cast iron pipes

An electrostatic spraying, ductile iron technology, applied in electrostatic spraying devices, liquid spraying equipment, coatings, etc., can solve the problems of unstable quality, uncontinuous production, low efficiency, etc., to improve safety factor and service life, improve pipe fittings Productivity, the effect of reducing safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The process of spraying DN800, 1-meter-long double-disk flange pipes with a spraying line, and spraying Aksu-blue epoxy powder is as follows:

[0054] (1) Ready to spray

[0055] A. The DN800, 1-meter-long double-disk flange pipe is sandblasted in advance, and some parts need to be repaired;

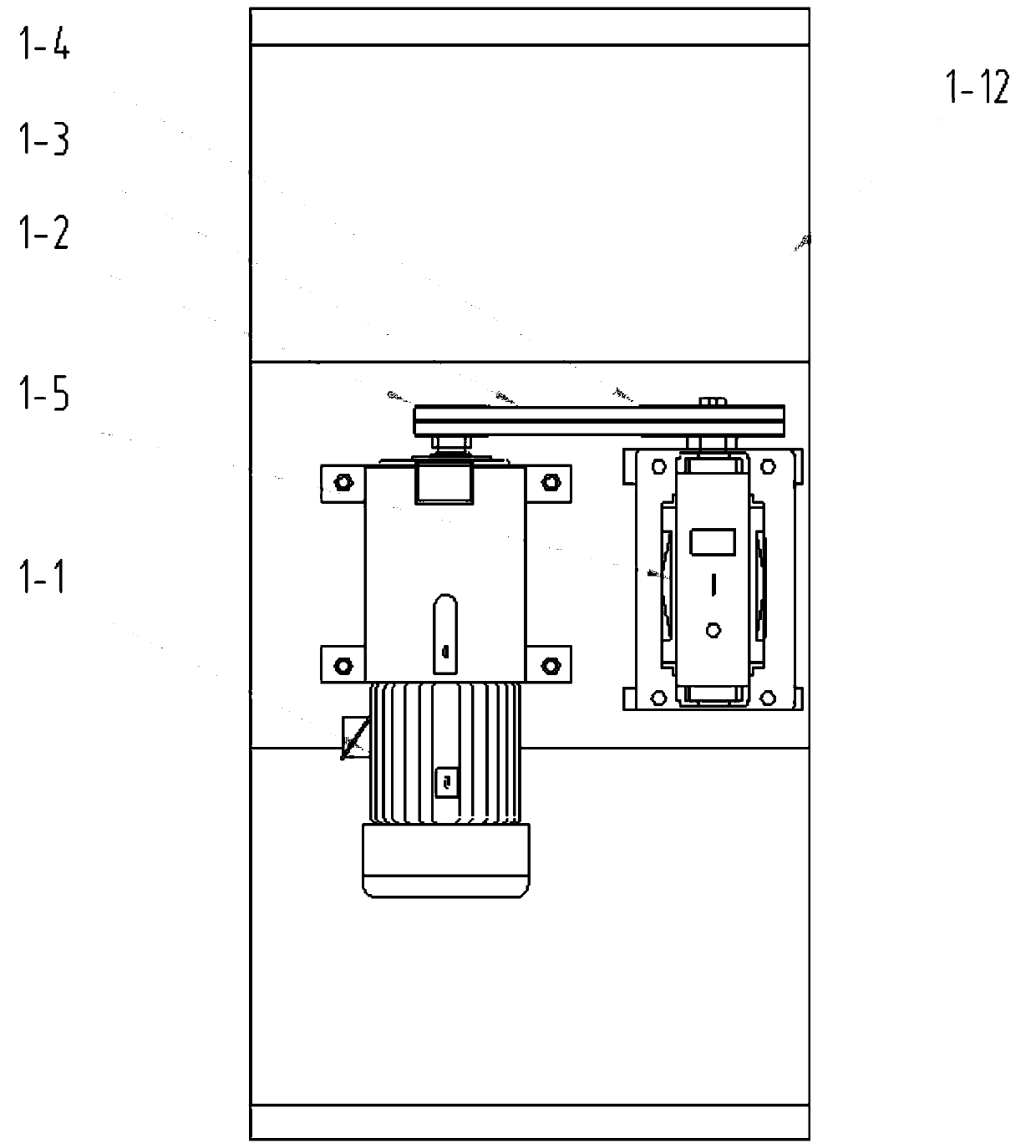

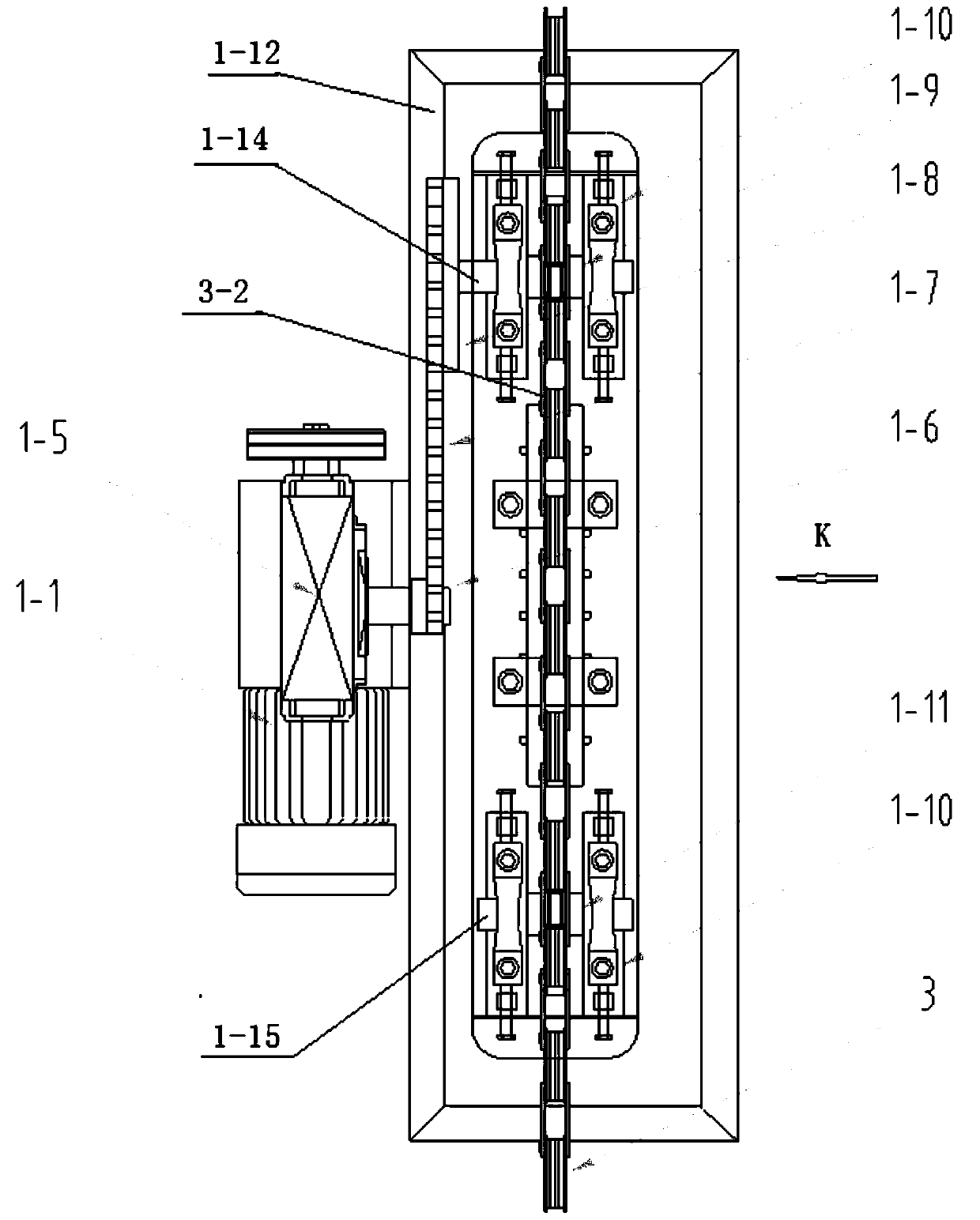

[0056] B. Select the color and brand of solid-solution-free powder required by the customer, and add it to the electrostatic spraying equipment 2 to prepare for spraying;

[0057] C. Set the temperature of the pre-baking oven 7 and the powder curing oven 13, and set the parameters of the electrostatic spraying equipment;

[0058] D. Do a good job of covering and protecting relevant parts according to the requirements of the workpiece;

[0059] E. Classify according to the specifications of the sprayed pipe fittings and the color of the sprayed powder, and then stack them in the loading area for epoxy spraying;

[0060] (2) Epoxy spraying

[0061] Hang the pipe fittings to be s...

Embodiment 2

[0069] Use the spraying line to spray the full-scale tee fittings of DN700×DN400, and the process of spraying Jiaming-black epoxy powder is as follows:

[0070] (1) Ready to spray

[0071] A. Pre-sandblast all DN700×DN400 tee fittings, and partially repair them;

[0072] B. Select the color and brand of solid-solution-free powder required by the customer, and add it to the electrostatic spraying equipment 2 to prepare for spraying;

[0073] C. Set the temperature of the pre-baking oven 7 and the powder curing oven 13, and set the parameters of the electrostatic spraying equipment;

[0074] D. Do a good job of covering and protecting relevant parts according to the requirements of the workpiece;

[0075] E. Classify according to the specifications of the sprayed pipe fittings and the color of the sprayed powder, and then stack them in the loading area for epoxy spraying;

[0076] (2) Epoxy spraying

[0077] Hang the pipe fittings to be sprayed in the loading area on the hangi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com