Ultrafast laser cleaning method and device for surface of aluminum alloy reflector

An ultra-fast laser and aluminum alloy technology, applied in cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of reducing surface reflectivity, reflectivity decline, surface quality deterioration, etc., to improve reflectivity and improve performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

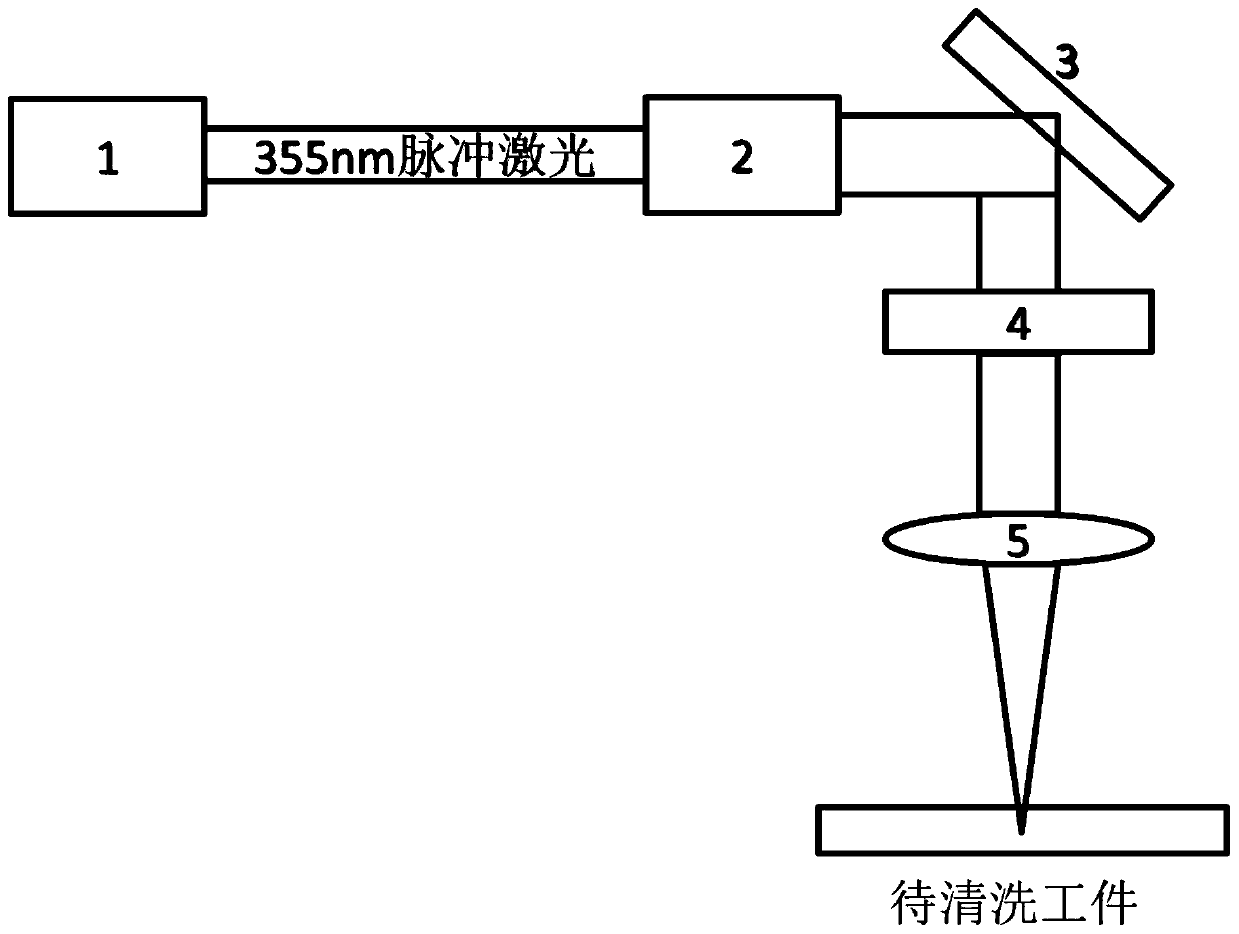

[0022] In order to solve the problem of black oxide layer formed on the surface after magnetorheology, resulting in deterioration of surface quality and serious decrease in reflectivity, the present invention proposes a method and device for ultrafast laser cleaning of the surface of metal materials using femtosecond laser, which will be described below Combined with examples, the method and device for ultrafast laser cleaning of the surface of the aluminum alloy reflector of the present invention will be further described in detail.

[0023] The implementation steps of the method for ultrafast laser cleaning the surface of the aluminum alloy mirror in this embodiment include:

[0024] 1) Conduct a photothermal absorption experiment on the aluminum alloy substrate and aluminum alloy oxide film corresponding to the workpiece to be cleaned, and record the wavelength range in which the photothermal absorptivity of the aluminum alloy oxide film is greater than the photothermal abso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap