A high-temperature-resistant, high-pressure, self-adaptive special pipeline cleaning equipment and its cleaning method

A technology of pipeline cleaning and high temperature resistance, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve problems such as affecting transportation capacity, secondary pollution, pipeline blockage, etc. The scope of action, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

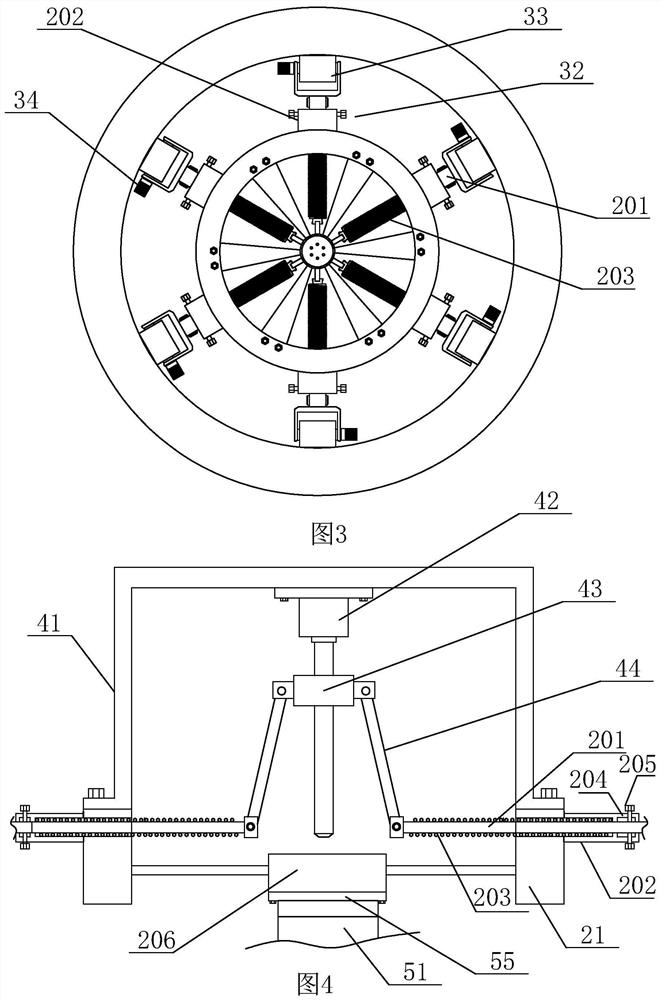

[0034] The present invention will be further preferably described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

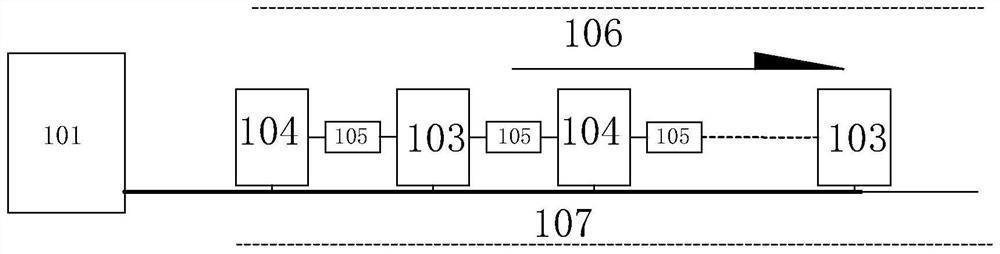

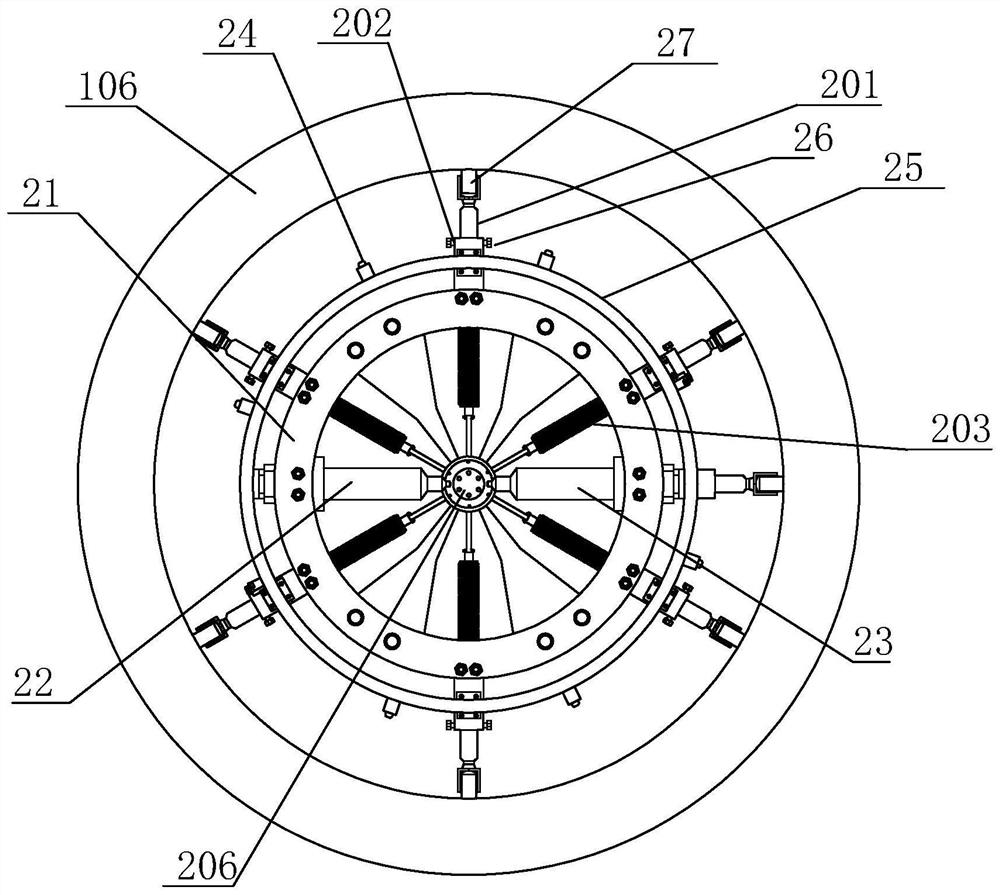

[0035] see Figure 1-Figure 6 , the present embodiment is a high-temperature-resistant, high-pressure, self-adaptive special pipeline 106 cleaning equipment, which is characterized in that: comprising

[0036] Pipeline cleaning device 104: used for cleaning special pipelines 106;

[0037] Traction device 103: used to walk in the special pipeline 106 and tow the pipeline cleaning device 104 to provide power;

[0038] Universal connector 105: used for connecting the traction device 103 and the pipeline cleaning device 104;

[0039] Centralized control management platform 101: used for the control and power supply of traction device 103 and universal connector 105;

[0040] The centralized control managem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com