An electromagnetic suction handling and stacking device based on vision and multi-sensing

A multi-sensing and electromagnetic chuck technology, which is applied in the directions of transportation and packaging, unstacking of objects, stacking of objects, etc., can solve the problems of high price, achieve low cost, ensure structural rigidity, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

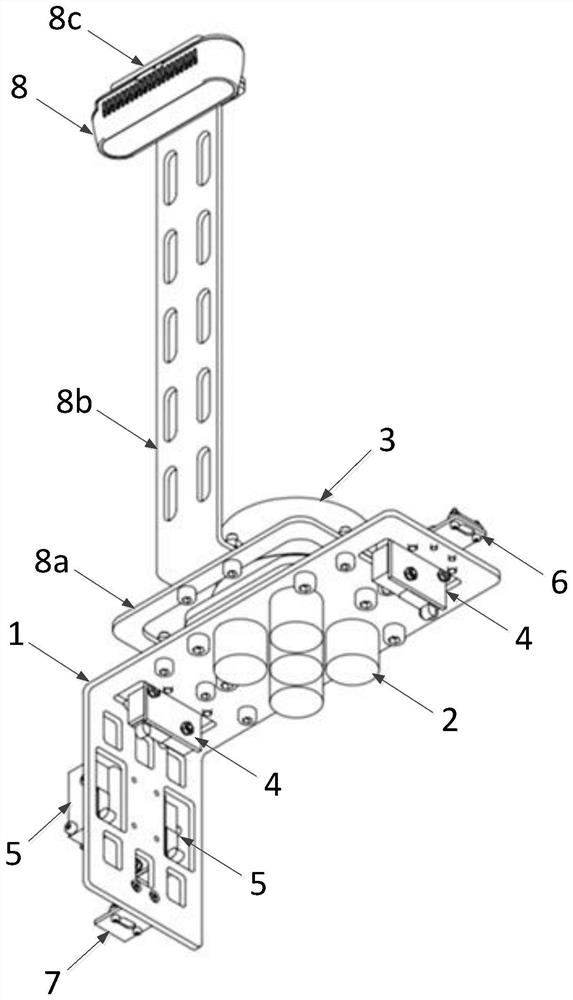

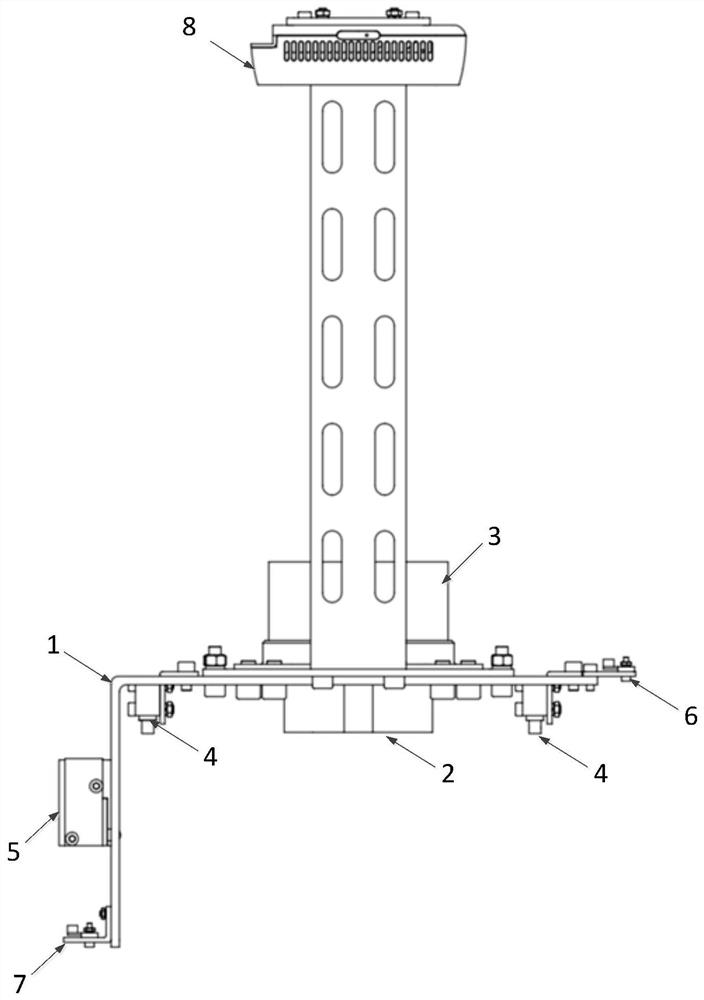

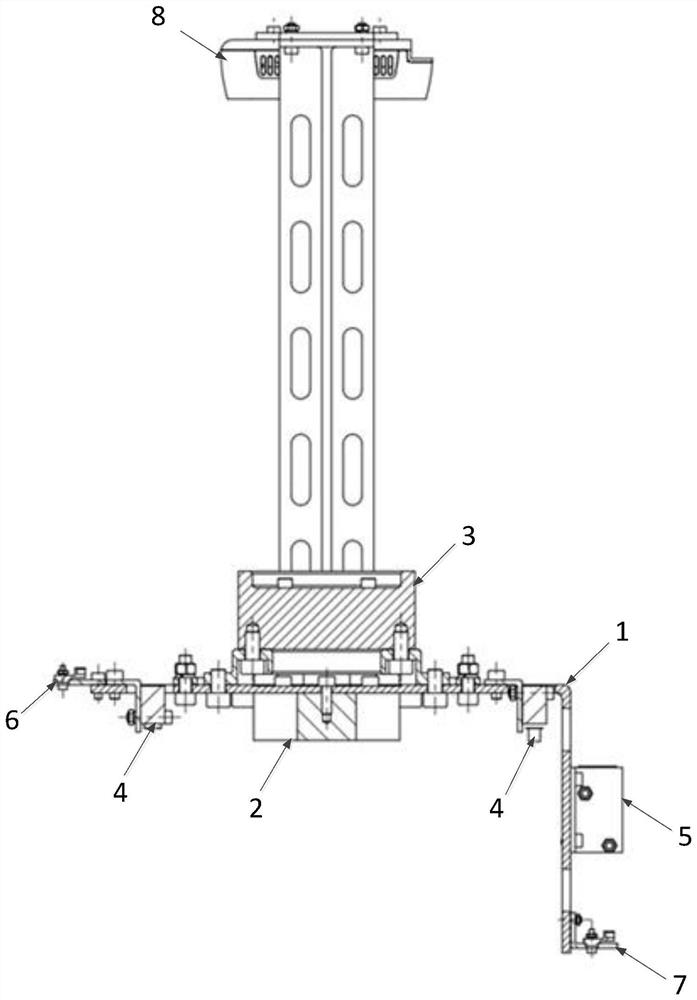

[0028] The present invention is based on the visual multi-sensing electromagnetic suction type handling and stacking device, including a limit mounting plate 1, an electromagnetic chuck 2, a force sensor 3 and a visual multi-sensing system, such as Figure 1~3 shown.

[0029] Wherein, the limit mounting plate 1 is used as the main body installation platform of the handling and stacking device of the present invention. In order to facilitate the handling and stacking operation tasks, it is designed as an L-shaped plate with a top surface and a rear side, and the middle part of the lower surface of the top surface is equipped with an electromagnetic sucker 2. The electromagnetic chuck 2 is used to suck the target article, and the electromagnetic chuck 2 is designed by the present invention to be composed of a plurality of electromagnets. In addition, the numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com