Three-dimensional movable precast concrete component production system

A prefabricated component and production system technology, which is applied in the direction of manufacturing tools, auxiliary molding equipment, ceramic molding machines, etc., can solve the problems of easy collision and damage of prefabricated components, large investment in transport vehicles, limited land area, etc., to achieve enhanced structural strength, Reverse shipping is time-consuming and labor-intensive, and the effect of occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

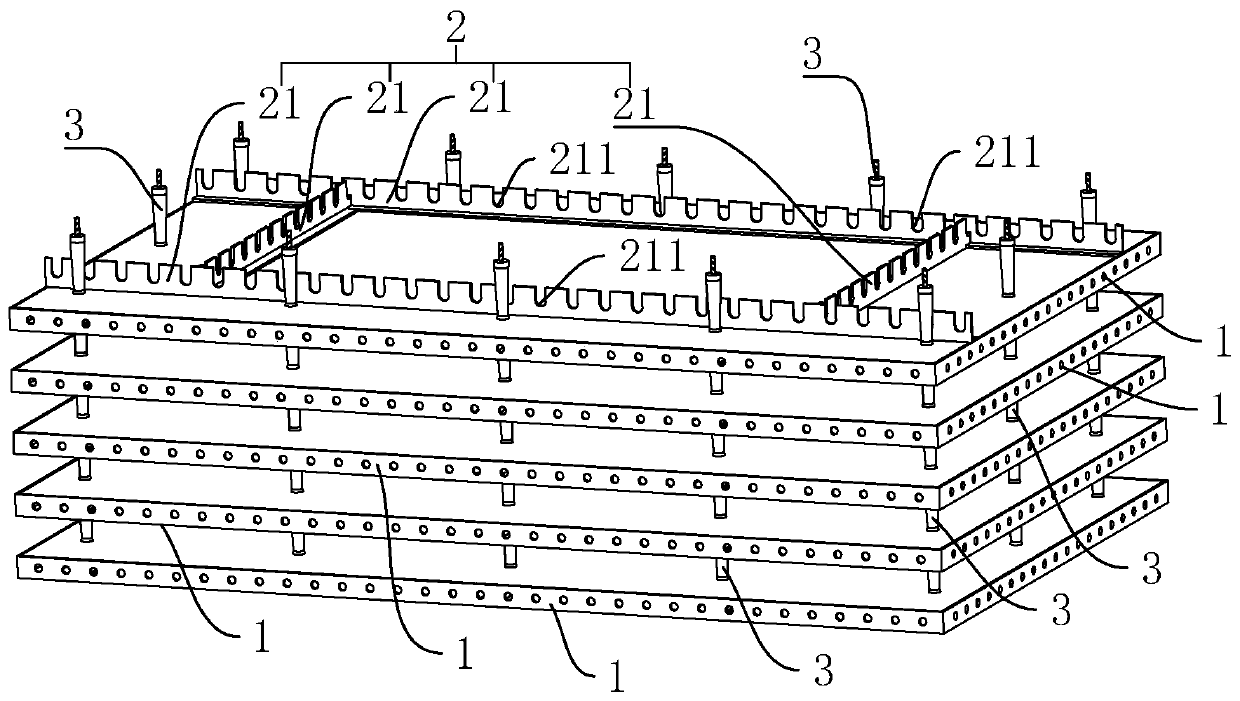

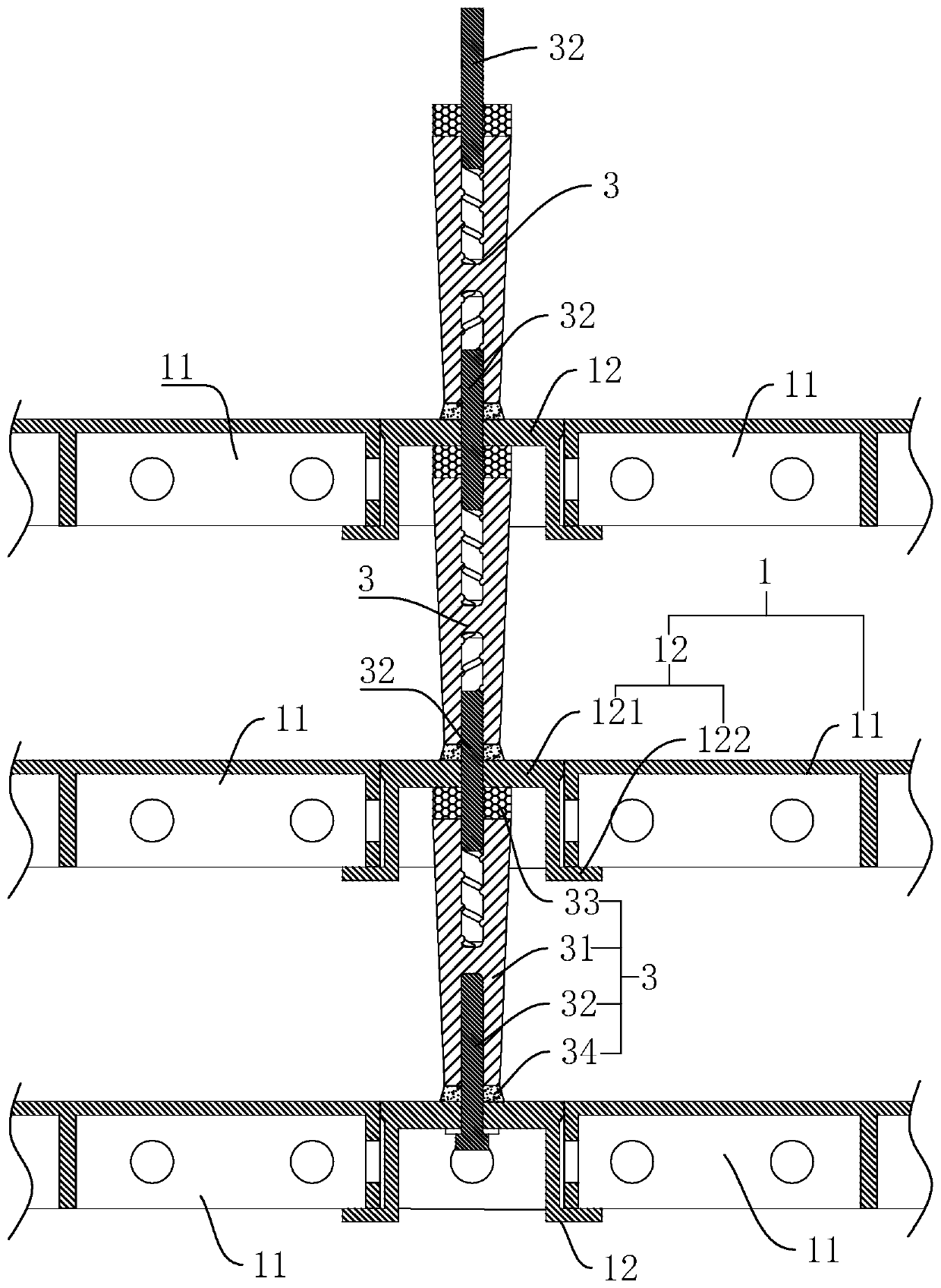

[0033] refer to figure 1 and figure 2 , is a three-dimensional movable concrete prefabricated component production system disclosed by the present invention, which is built on the construction site of a prefabricated building, including: a formwork plate 1, a pouring frame 2 and a support member 3. There are multiple formwork panels 1 and they are vertically spaced and stacked. Adjacent formwork panels 1 are supported by a plurality of supports 3, and the supports 3 and formwork panels 1 are detachably assembled. The upper surface of 1 is flat, and the pouring frame 2 is fixed on the upper surface of the formwork plate 1 to form the pouring cavity of the concrete prefabricated component.

[0034] The main body of the formwork plate 1 is spliced by a plurality of aluminum formworks 11, and the adjacent aluminum formworks 11 are fixedly connected by bolt g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com