A method for preparing thin films by transferring sublimable materials from bulk to substrate under non-vacuum conditions

A non-vacuum, bulk technology, used in sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, electrical components, etc. Difficulty and cost problems, achieve the effect of controllable film thickness and solve the difficulty of orthogonal solvent selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

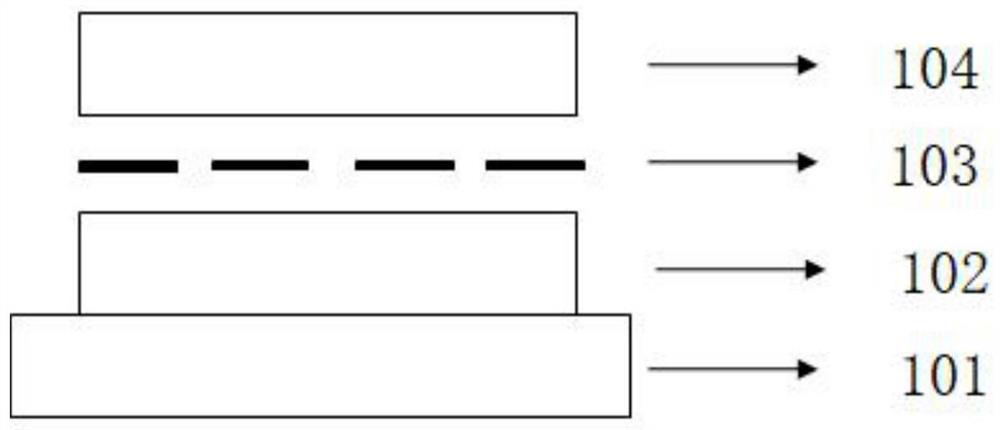

[0036] Fabrication of Upright Organic Electroluminescent Devices Containing Monolayer Transferred Light-Emitting Layers

[0037] Monolayer film transfer at atmospheric pressure

[0038] In this example, the organic thin film is prepared by the heating transfer method under normal pressure, and the schematic diagram of the technical process is as follows figure 1 As shown, in the specific method, the glass substrate (101) and the ITO glass (104) without a receiving medium are first subjected to ultraviolet ozone treatment for 20 minutes, and the specific process can refer to methods known in the art, such as references (J.Phys. Chem. Lett. 2018, 9, 1547-1553). First spin the conductive polymer-poly(3,4-ethylenedioxythiophene)-polystyrenesulfonic acid (PEDOT:PSS) on the ITO glass and bake it at 120°C for 10 minutes, then spin it with chlorobenzene solution Apply a layer of conductive polymer polyvinylcarbazole (PVK) and bake at 120°C for 10 minutes; then, drop 9,9-dimethyl-10-...

Embodiment 2

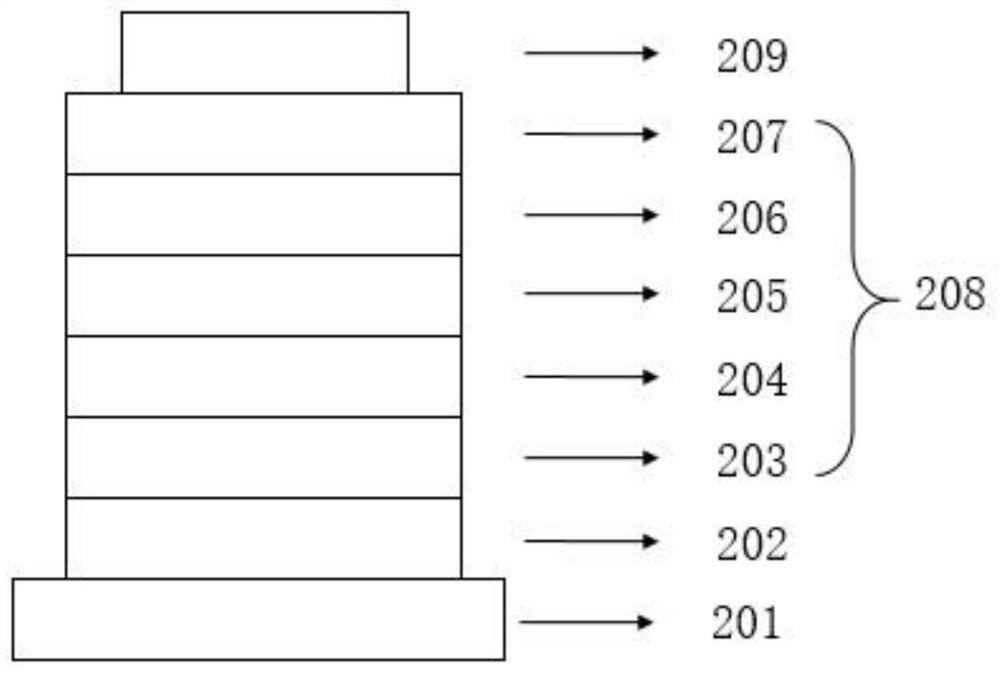

[0043] Light-emitting preparation of positive organic electroluminescent devices containing double-layer transfer materials;

[0044] Bilayer film transfer at atmospheric pressure

[0045] In this embodiment, the thin film is prepared by the normal pressure heating transfer method. The specific method is to first conduct the ultraviolet ozone treatment on the conductive glass (ITO) substrate and the ordinary glass substrate for 20 minutes. The specific process can refer to methods known in the art, such as references ( J. Phys. Chem. Lett. 2018, 9, 1547-1553). First spin PEDOT:PSS on the ITO glass and bake it at 120°C for 10 minutes, then spin-coat a layer of dendritic compound 10,10'-(sulfonyl(4,1-phenylene) with chlorobenzene solution )) bis(2,7-bis(3,6-di-tert-butyl-9H-carbazol-9-yl)-9,9-dimethyl-9,10-dihydroacridine (4CzDMAC- DPS); Then, drip the 1:1 mixed solution of chlorobenzene and chloroform of DPEPO on the glass sheet that ultraviolet ozone is processed, spin 30 se...

Embodiment 3

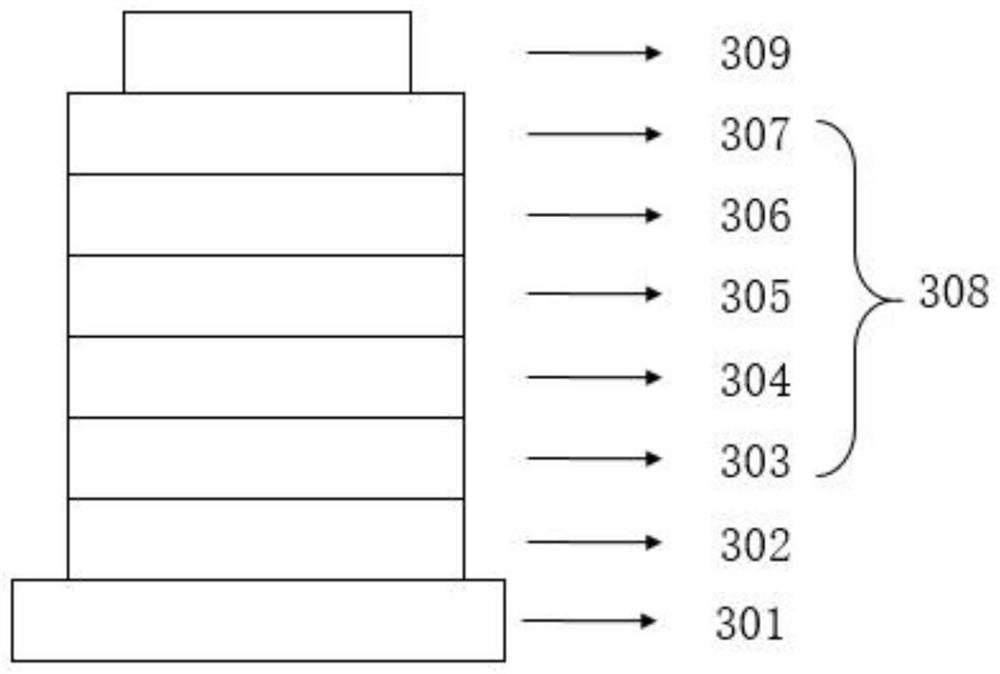

[0050] Fabrication of Perovskite Electroluminescent Devices Containing a Monolayer Transferred Electron Transport Layer

[0051] Monolayer film transfer at atmospheric pressure

[0052] In this embodiment, the thin film is prepared by the normal pressure heating transfer method. The specific method is to first conduct the ultraviolet ozone treatment on the conductive glass (ITO) substrate and the ordinary glass substrate for 20 minutes. The specific process can refer to methods known in the art, such as references ( J. Phys. Chem. Lett. 2018, 9, 1547-1553). First spin PEDOT:PSS on the ITO glass and bake it at 120°C for 10 minutes, then spin coat a layer of methylamine bromide with a mixed solution of dimethylsulfoxide (DMSO) and dimethylformamide (DMF) Lead (MAPbBr 3 ), the solution preparation process can refer to methods known in the art, such as references (ACS Nano, 2017, 11, 3311-3319); then, drop 4,7 on another glass substrate that has been cleaned and treated with ult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com