A kind of method for selectively recovering copper from chloride mixed solution

A technology of chloride and copper chloride, which is applied in the field of hydrometallurgy and circular economy, can solve the problems of difficult recycling of copper, and achieve the effect of saving costs and solving difficult selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

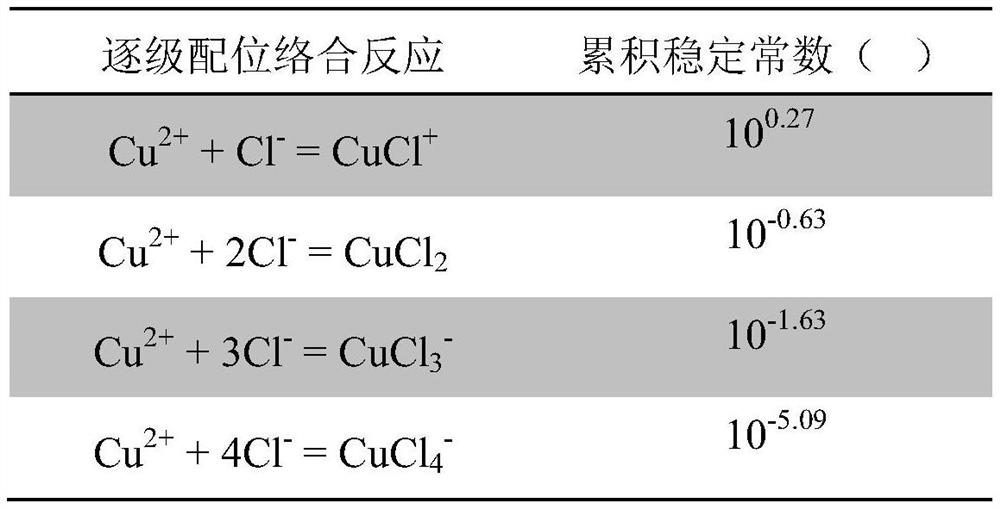

Method used

Image

Examples

Embodiment 1

[0027]Using the copper chloride mixed solution produced by a certain enterprise in the production process of germanium as raw material, the content of copper in the raw material solution reaches 12.8g / L, and the content of germanium is 1.2g / L, and is recovered from the mixed solution of chloride through the following steps copper:

[0028] Add manganese chloride to the chloride mixture so that the concentration of chloride ions in the entire system rises to 7mol / L, then control the temperature at 25°C and shake for 0.5h, keep the temperature of the entire system at 25°C after the complexation is complete, use The peristaltic pump controls the injection rate to be 1BV / h (meaning that the volume of the solution passing through the ion exchange column per hour is 1 times the volume of the loaded resin bed) and passes through the loaded D201 anion exchange resin bed in the way of "top in and bottom out". layer. Then, the residual adsorption liquid was diluted by corresponding tim...

Embodiment 2

[0030] Using the copper chloride mixed solution produced by a certain enterprise in the production process of germanium as raw material, the content of copper in the raw material solution reaches 12.8g / L, and the content of germanium is 1.2g / L, and is recovered from the mixed solution of chloride through the following steps copper:

[0031] Add calcium chloride to the chloride mixture to increase the concentration of chloride ions to 9mol / L, then control the temperature at 15°C and shake for 1.5h, keep the temperature of the entire system at 15°C after the complexation is complete, and use a peristaltic pump to control The injection rate is 1BV / h, and the 201×4 anion exchange resin bed is loaded in the way of “top in and bottom out”. Then the adsorption residual liquid was diluted by corresponding times and then sent to ICP for analysis. Finally, the separation and recovery rate of copper was 90.57%, and the adsorption rate of germanium was 0.19%. For the saturated resin bed,...

Embodiment 3

[0033] Using the copper chloride mixed solution produced by a certain enterprise in the production process of germanium as raw material, the content of copper in the raw material solution reaches 19.2g / L, and the content of germanium is 0.8g / L, and is recovered from the mixed solution of chloride through the following steps copper:

[0034] Add calcium chloride to the chloride mixture to increase the concentration of chloride ions to 7mol / L, then control the temperature at 25°C and shake for 1 hour, keep the temperature of the entire system at 25°C after the complexation is complete, and use a peristaltic pump to control the The sample rate is 2BV / h, and the D201 anion exchange resin bed is loaded in the way of "top in and bottom out". Then the adsorption residual liquid was diluted by a corresponding multiple and then sent to ICP for analysis. Finally, the separation and recovery rate of copper was 89.10%, and the adsorption rate of germanium was 0.23%. For the saturated res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com