Device for producing alkylated aromatic compounds

A technology for alkylating aromatic compounds, applied in the direction of hydrocarbons, hydrocarbons, carbon compound catalysts, etc., can solve the problems of limited capacity and low adsorption efficiency of adsorbents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

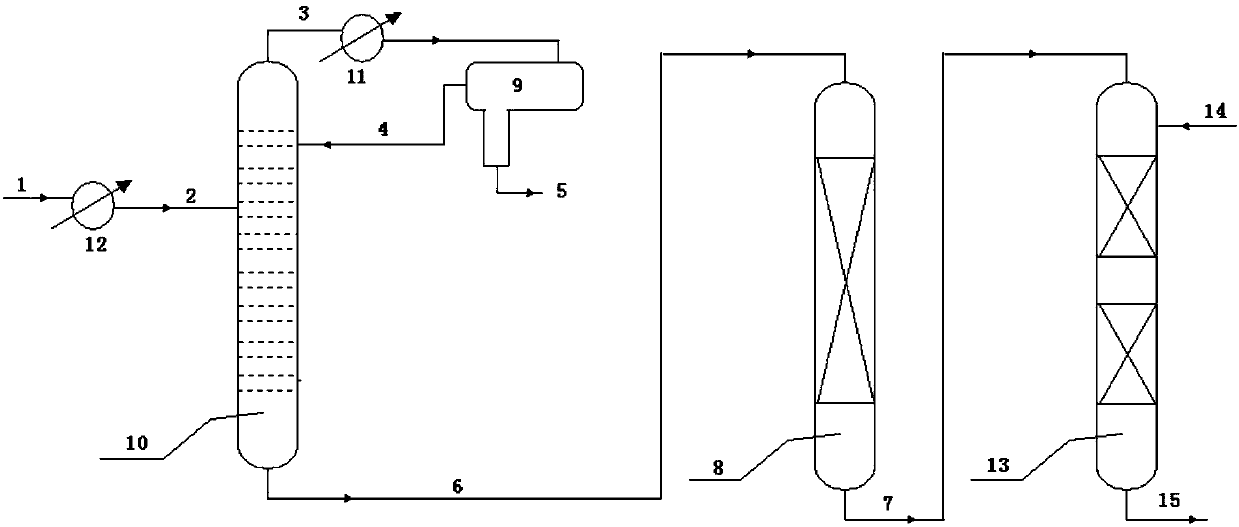

[0043] press figure 1 In the device, the raw material benzene has a water content of 200ppm, a total nitrogen content of 3ppm, a total sulfur content of 0.7ppm, a distillation tower operating pressure of 0.01Pa, a tower top temperature of 80°C, and a tower bottom temperature of 82°C. The adsorbent bed is filled with 100g acid clay, the adsorbent bed temperature is 82℃, the pressure is 0.5MPa, and the benzene weight space velocity is 5.0h -1 . After continuous operation for 100 hours, the total nitrogen content at the outlet of the adsorbent bed was analyzed by a sulfur and nitrogen analyzer to be 0.05 ppm, and the total sulfur content was 0.06 ppm. .

[0044] Using the purified benzene as the raw material, the alkylation of benzene and propylene is the target reaction. The reaction conditions are: fixed bed reactor, catalyst is acid Beta zeolite, reaction temperature 160℃, reaction pressure 3.0MPa, propylene weight space velocity 10.0h -1 , The molar ratio of benzene to propyle...

Embodiment 2

[0046] [Example 1] Purified benzene is used as the raw material, and the alkylation of benzene and ethylene is the target reaction. The reaction conditions are: fixed bed reactor, the catalyst is acid Beta zeolite, the reaction temperature is 205°C, and the reaction pressure is 4.5MPa. Ethylene weight space velocity 3.0h -1 , The molar ratio of benzene to ethylene is 4.0, the continuous reaction is 200 hours, and the ethylene conversion rate reaches 99%.

Embodiment 3

[0048] press figure 1 In the device, the raw material benzene has a water content of 500ppm, a total nitrogen content of 3ppm, a total sulfur content of 1.6ppm, a distillation tower operating pressure of 0.6MPa, a tower top temperature of about 140°C, and a tower bottom temperature of 160°C. The adsorbent bed is filled with 100g acid Beta zeolite, the adsorbent bed temperature is 160℃, the pressure is 2.0MPa, and the benzene weight space velocity is 3.0h -1 . After continuous operation for 100 hours, the total nitrogen content at the outlet of the adsorbent bed was analyzed by a sulfur-nitrogen analyzer to be 0.05 ppm, and the total sulfur content was 0.07 ppm.

[0049] Using the purified benzene as the raw material, the alkylation of benzene and propylene is the target reaction. The reaction conditions are: fixed bed reactor, catalyst is acid Beta zeolite, reaction temperature 160℃, reaction pressure 3.0MPa, propylene weight space velocity 10.0h -1 , The molar ratio of benzene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com