Preparation method of graphene modified hydrophobic activated carbon

A graphene modification, activated carbon technology, applied in separation methods, chemical instruments and methods, climate sustainability, etc., can solve problems such as reduced adsorption capacity, and achieve the effect of increasing hydrophobicity and ensuring regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

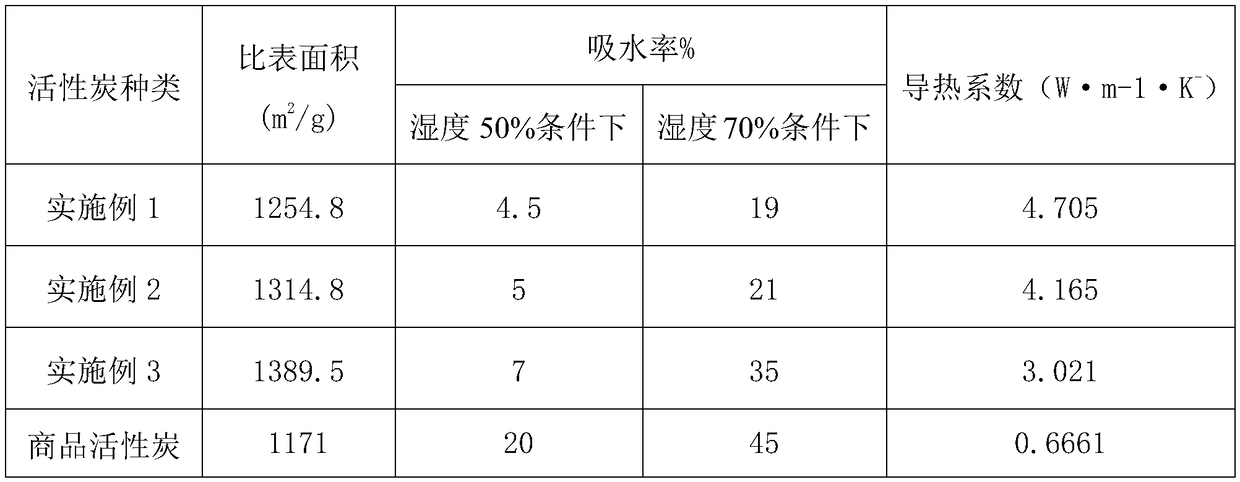

Examples

Embodiment 1

[0019] A preparation method of graphene-modified hydrophobic activated carbon, comprising the following steps:

[0020] S1. Clean the hard fruit shells, dry them, pulverize them with a pulverizer, and sieve them to obtain fruit shell powders with a mesh size below 200; the hard fruit shells include coconut shells, apricot core shells, walnut shells, and peach shells.

[0021] S2, take by weighing 100 grams of fruit shell powder and 350 mL of ZnCl with a concentration of 0.3 g / mL 2 -HCl solution is mixed evenly, add 30 grams of graphene, and add 20mL self-made dispersant simultaneously, described self-made dispersant is polyvinylpyrrolidone (PVP) and sodium lignosulfonate (SLS) mixed solution, and concentration is 5g / L, The mass ratio of polyvinylpyrrolidone and sodium lignin sulfonate in the mixed solution is 4:1; Ultrasound in an ultrasonic instrument for 30-60min, so that the graphene and the husk powder are evenly mixed and dispersed in the solution, and then mixed The sol...

Embodiment 2

[0025] A preparation method of graphene-modified hydrophobic activated carbon, comprising the following steps:

[0026] S1. Clean the hard fruit shells, dry them, pulverize them with a pulverizer, and sieve them to obtain fruit shell powders with a mesh size below 200; the hard fruit shells include coconut shells, apricot core shells, walnut shells, and peach shells.

[0027] S2, take by weighing 100 grams of fruit shell powder and 600 mL of ZnCl with a concentration of 0.5 g / mL 2 -HCl solution is mixed evenly, adds 20 grams of graphene, and adds 20mL self-made dispersant simultaneously, and described self-made dispersant is the mixed solution of PVP and sodium lignosulfonate (SLS), and concentration is 5g / L, and the polymer in the mixed solution The mass ratio of vinylpyrrolidone and sodium lignosulfonate is 4:3; Ultrasonic 30-60min in ultrasonic instrument, makes graphene and fruit shell powder mix evenly and evenly disperse in solution, then mix solution in 60-80 The react...

Embodiment 3

[0031] A preparation method of graphene-modified hydrophobic activated carbon, comprising the following steps:

[0032] S1. Clean the hard fruit shells, dry them, pulverize them with a pulverizer, and sieve them to obtain fruit shell powders with a mesh size below 200; the hard fruit shells include coconut shells, apricot core shells, walnut shells, and peach shells.

[0033] S2, take by weighing 100 grams of fruit shell powder and 1000 mL concentration of ZnCl of 0.2 g / mL 2 -HCl solution is mixed evenly, adds 10 grams of graphene, and adds 10mL self-made dispersant simultaneously, and described self-made dispersant is the mixed solution of PVP and sodium lignosulfonate (SLS), and concentration is 5g / L, and the polymer in the mixed solution The mass ratio of vinylpyrrolidone and sodium lignosulfonate is 4:2; Ultrasonic 30-60min in ultrasonic instrument, makes graphene and fruit shell powder mix evenly and evenly disperse in solution, then mix solution in 60-80 The reaction wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com