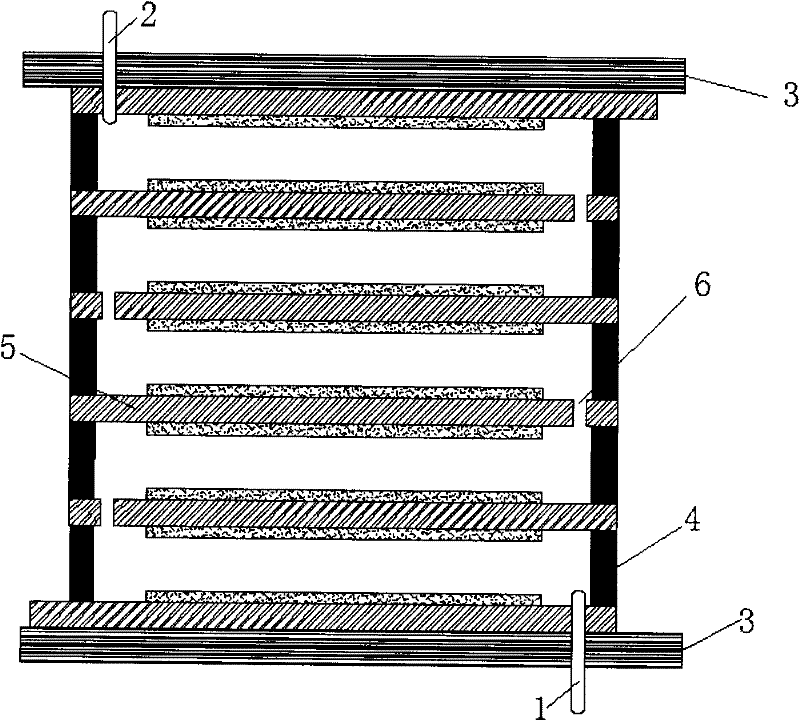

Electro adsorption water treatment module

A water treatment and electro-adsorption technology, applied in ion exchange column/bed method, separation method, dispersed particle separation, etc., can solve the problems of decreased electro-adsorption efficiency, inconsistent electrode plate spacing, limited stirring effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

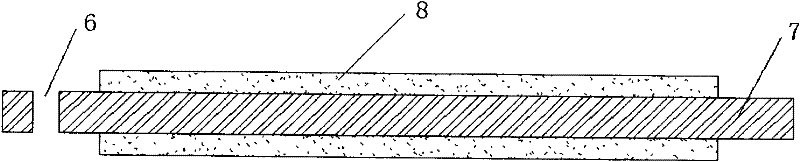

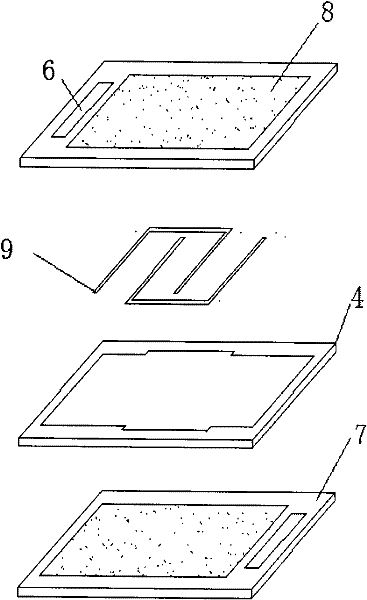

Method used

Image

Examples

Embodiment

[0026] Module 1, the electrode material is activated carbon, the thickness of the gasket is 2cm, the voltage is 1.2V, 10 electrode plates, there are baffles between the electrode plates, and only the uppermost and the lowermost two electrode plates are connected to the power supply. When the solution with a concentration of 2000μs / cm passes through the module at 0.6L / h, the effluent concentration is 861μs / cm.

[0027] Module 2, the electrode material is activated carbon, the thickness of the gasket is 2cm, the voltage is 1.2V, and 10 electrode plates are connected to the power supply. When the solution with a concentration of 2000μs / cm passes through the module at 0.6L / h, the effluent concentration is 1227μs / cm.

[0028]Module 1 is an electro-adsorption water treatment module made according to the present invention, and module 2 is a comparison module, and the comparison data are in Table 1.

[0029] Table 1

[0030] module

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com