Glass fiber reinforced plastic winding forming and pultrusion process

A technology of winding molding and pultrusion technology, which is applied in the field of FRP winding molding and pultrusion technology, which can solve the problems of low pultrusion processing efficiency, single winding pultrusion, and single temperature change of FRP, etc., to improve the efficiency of winding molding , improve efficiency, and the effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

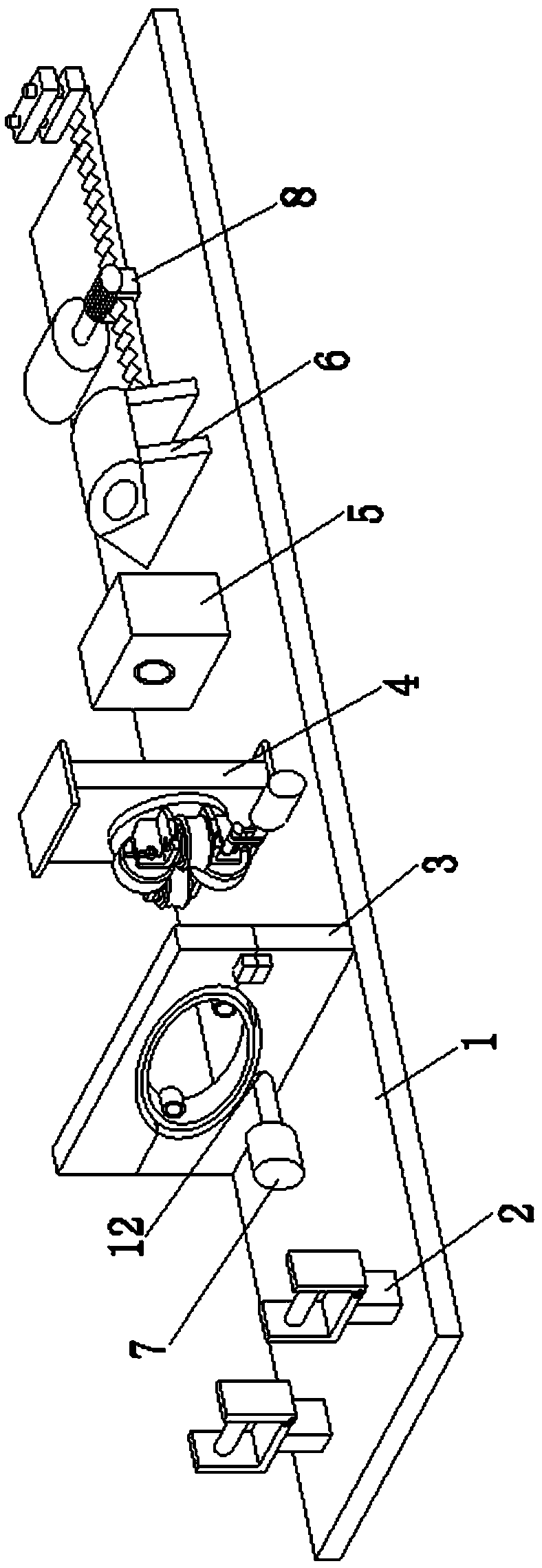

[0037] Such as Figure 1-9 As shown, a glass fiber reinforced plastic winding forming and pultrusion process includes steps 1) glass fiber reinforced plastic winding; step 2) preforming; step 3) primary heating pultrusion setting; step 4) secondary heating pultrusion setting.

[0038] Specific steps are as follows:

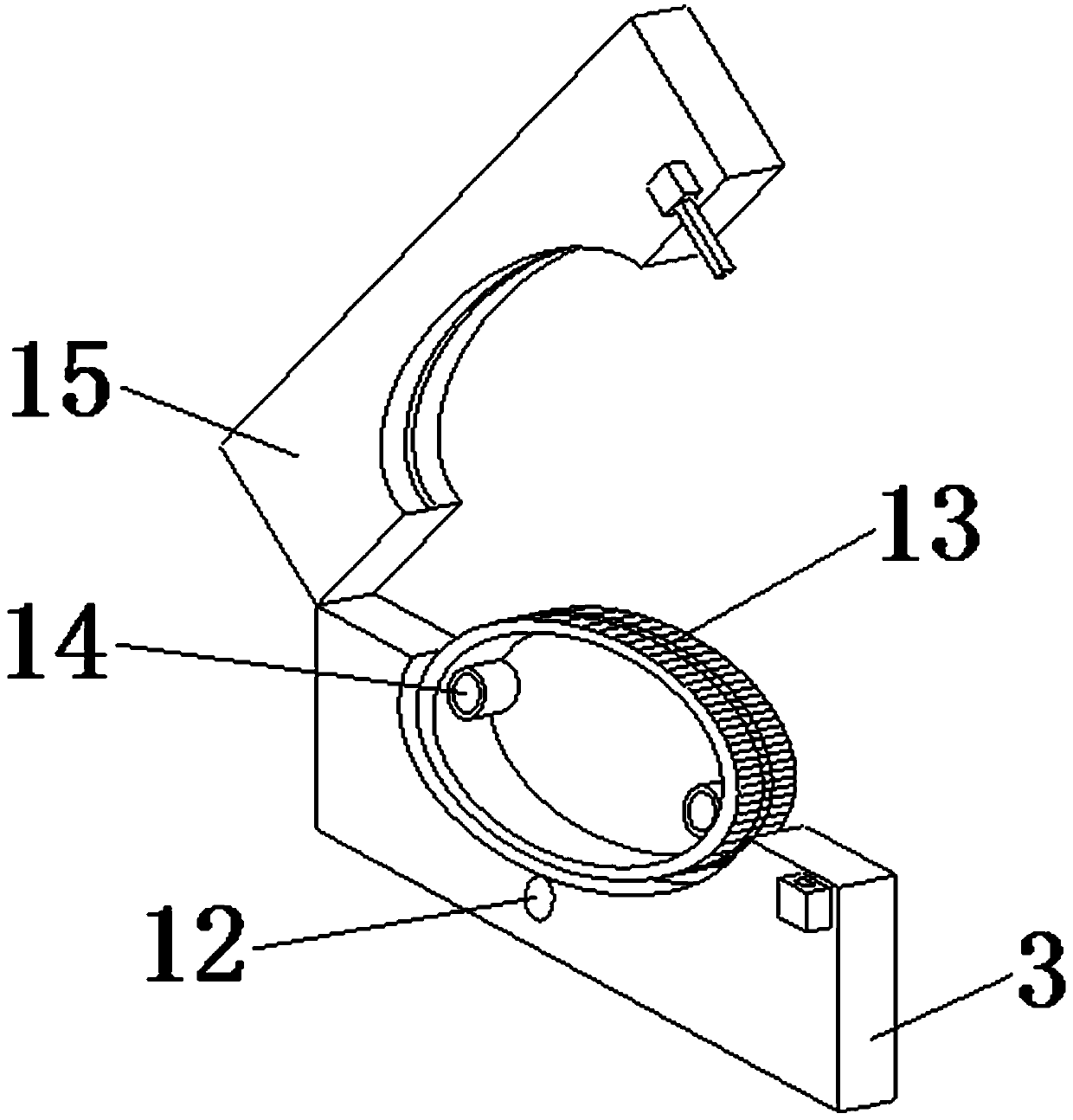

[0039] Step 1) FRP winding: Install the glass steel wire to be processed on the two sets of shafts (10), clamp one end of the glass steel wire inside the fastening ring (14) with a clamp, and control the control panel to make the No. 1 motor (7) ) Work, the No. 1 motor (7) rotates so that the No. 1 gear (12) drives the hollow gear (13) to rotate. The glass steel wires inside the two sets of fastening rings (14) are wound together to form. After winding for a certain period of time, the two sets of The glass steel wire at the shaft (10) end is cut off;

[0040] Step 2) Pre-forming: Put one end of the glass steel wire cut in step 1) into the silo (28), control the contro...

Embodiment 2

[0047] Such as figure 1 As shown, a glass fiber reinforced plastic winding forming and pultrusion device includes a workbench 1, and the upper end of the workbench 1 is sequentially installed with a feeding device, a winding device, a preforming device, a primary heating device, a secondary heating device, and The pultrusion device, through which the winding of two groups of glass steel wires and the pre-forming of the glass steel wires after winding can be realized in sequence.

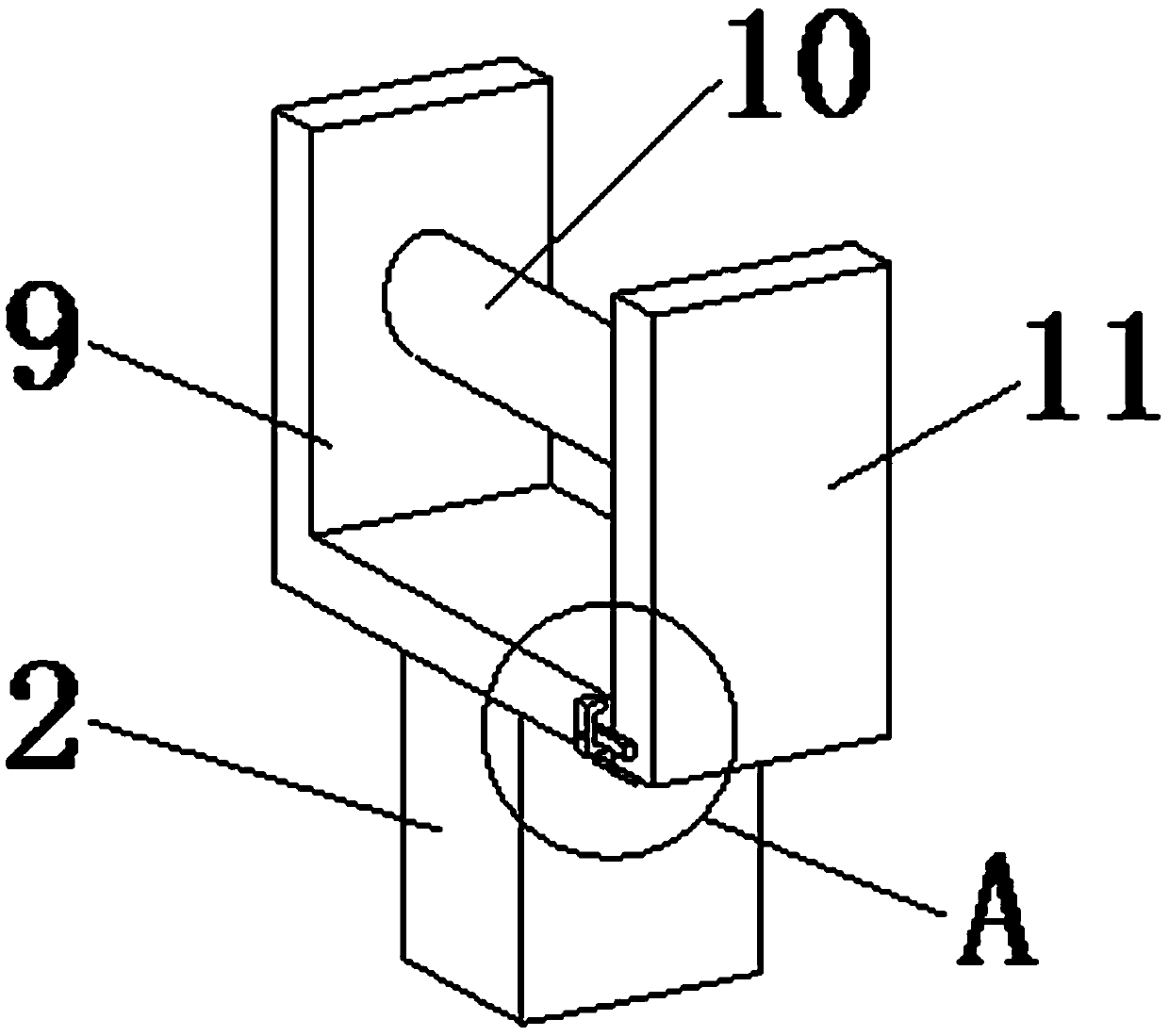

[0048] Such as figure 1 , figure 2 versus Figure 7 As shown, the feeding device includes two sets of bases 2, and the two sets of bases 2 are installed on the workbench 1. The upper ends of the two sets of bases 2 are fixedly installed with a mounting seat 9, and the bottom side of the mounting seat 9 passes through a hinge A movable plate 11 is movably installed, a sleeve shaft 10 is fixedly installed on the upper end side of the mounting seat 9, and the sleeve shaft 10 is located on one side of the m...

Embodiment 3

[0052] Such as figure 1 As shown, a glass fiber reinforced plastic winding forming and pultrusion device includes a workbench 1, and the upper end of the workbench 1 is sequentially installed with a feeding device, a winding device, a preforming device, a primary heating device, a secondary heating device, and The pultrusion device, through which the initial heating pultrusion setting of the pre-formed FRP and the secondary heating pultrusion setting of the first heating pultrusion setting FRP can be realized in sequence to process the required FRP products.

[0053] Such as figure 1 versus Image 6 As shown, the primary heating device includes a No. 1 heating box 5, the No. 1 heating box 5 is installed on the workbench 1, the No. 1 heating box 5 is provided with a No. mold cavity 29 therethrough, and the No. 1 heating box 5 is wound with Electric heating wire, and the electric heating wire is wound outside the first cavity 29;

[0054] The secondary heating device includes a suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com