Propellant-carrying winding combined core mold

A combined, drug-carrying technology, which is applied in jet propulsion devices, rocket engine devices, machines/engines, etc., can solve the problems of difficult release of charge performance and few applications, shorten the development cycle, simplify the overall structure, and form the process simplified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

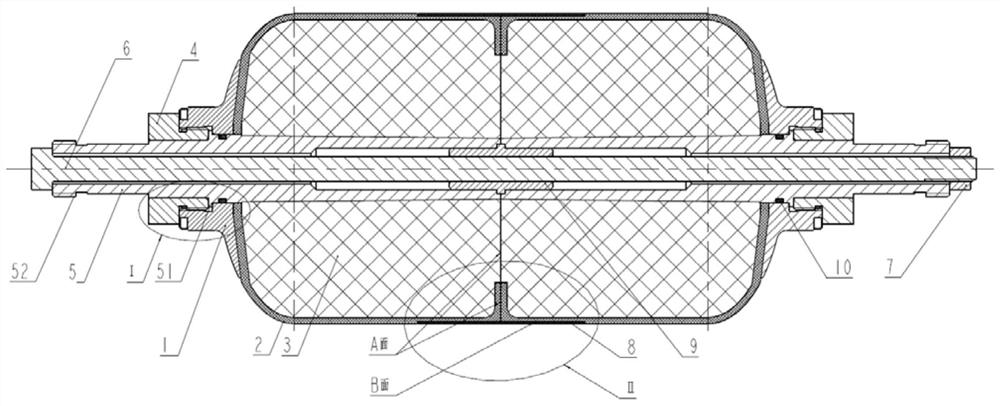

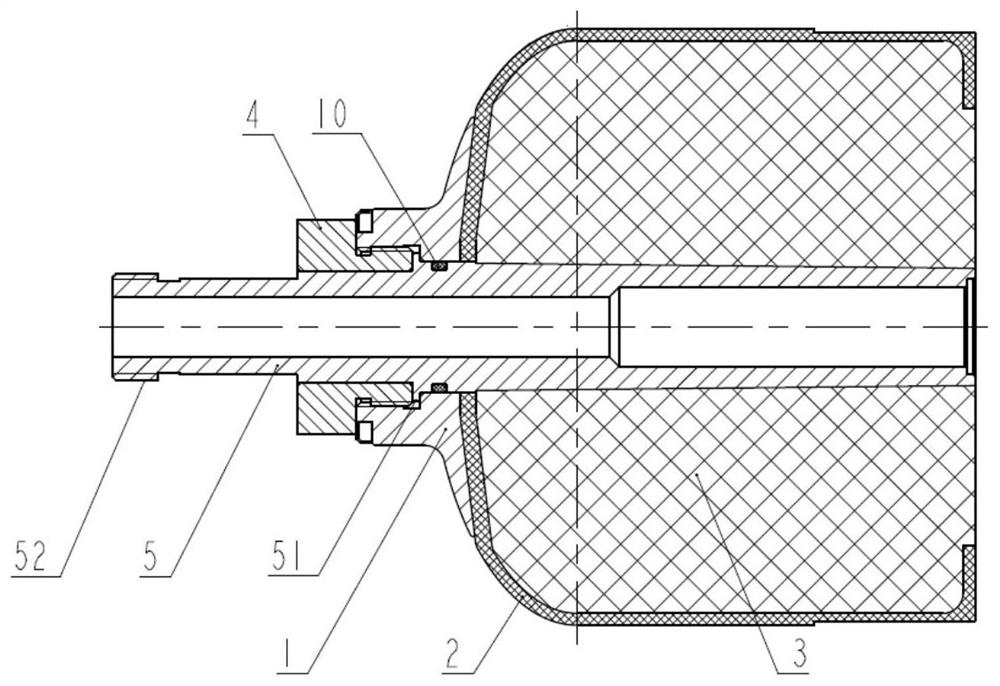

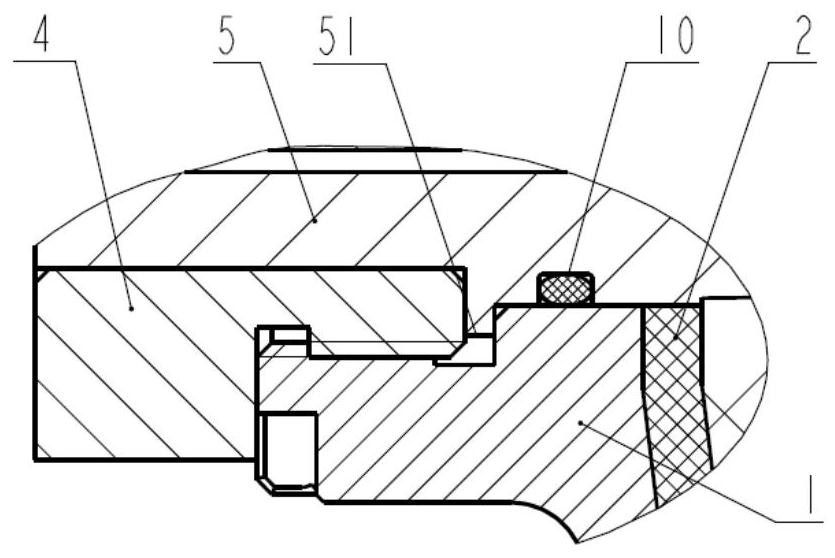

[0056] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0057] The invention discloses a compound winding mandrel with medicine, which is integrated with the propellant and the heat insulation layer by using the mandrel charged with the medicine, and meets the forming requirements of the wound compound shell with medicine. Surface molding, using the core column as the winding shaft, enhances the strength and rigidity of the compound winding mandrel with medicine, meets the requirements of charging and winding at the same time, and avoids the problems of complex structure and cumbersome molding process of the compound winding mandrel with medicine .

[0058] Light weight and high energy are the development trend of the new generation of solid rocket motors. The composite shell is made of non-metallic materials. The application of high-strength ratio fiber materials can effectively reduce the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com