Environment-friendly electric push rod lifting platform

A technology of electric push rods and lifting platforms, which is applied in the direction of lifting frames, lifting devices, etc., can solve the problems of inability to adapt to automation, intelligence, inability to perform precise control, and unfriendly environment, and achieve compact structure, improved positioning accuracy, and energy saving. The effect of thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

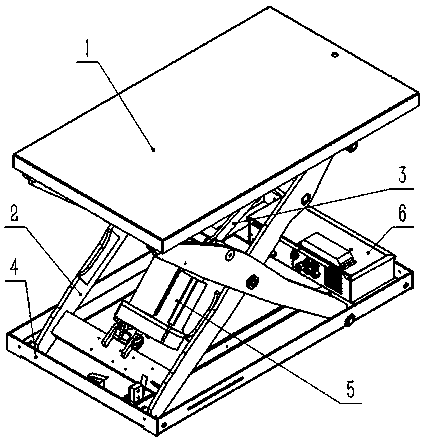

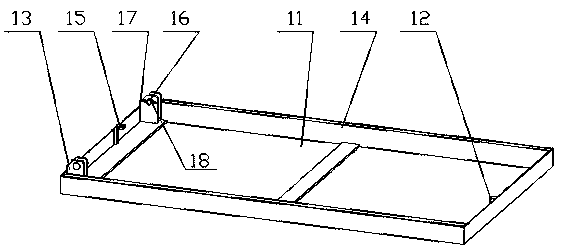

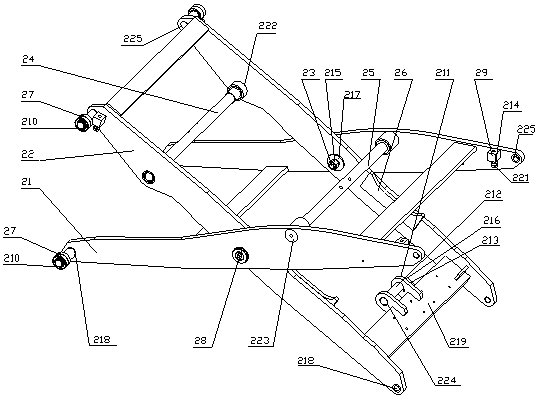

[0020] Such as figure 1 As shown, an environment-friendly electric push rod lifting platform includes a table device 1, a scissor device 2, a conversion device 3, a chassis device 4, an electric push rod 5, and an electrical control device 6; one end of the chassis device 4 is equipped with an electrical control device 6. The limit travel switch 48 and the lower limit travel switch 45 on the chassis device 4 are connected to the servo controller 611 of the electric control device 6 . The chassis device 4 is connected with the oil-free bearing II 218 of the inner scissors 22 and the outer scissors 21 of the scissors device 2 through the pin shaft III 42 on the fixed seat 44 . An electric push rod 5 is installed on the ear plate 211 of the scissor device 2 , and a conversion device 3 is installed on the transition shaft I 24 and the transition shaft II 25 of the scissor device 2 . The oil-free bearing VI225 of the scissor device 2 is connected with the fixed seat 13 of the tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com