A kind of underglaze color pigment and its preparation method and application

A kind of underglaze color and pigment technology, applied in the direction of fibrous filler, etc., can solve the problems of poor hydrophilicity of pigments, difficulty in glazing, low strength of pigments, etc., achieve clear color, not easy to break, and improve the effect of color development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

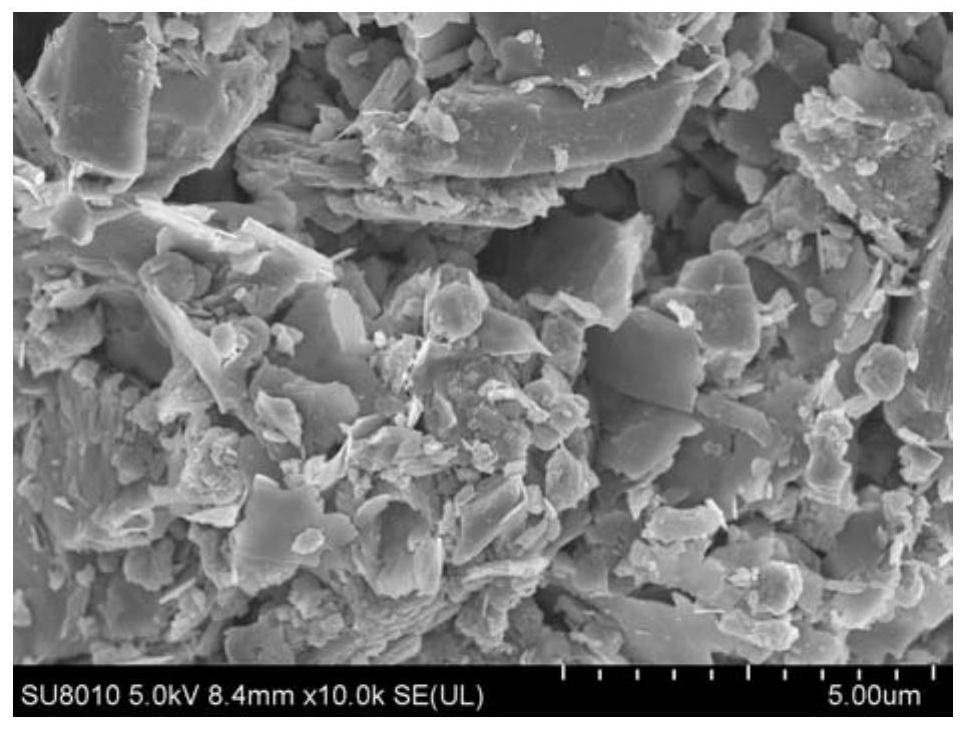

Image

Examples

Embodiment 1

[0046] This embodiment provides an underglaze color pigment with a particle size of less than 3 μm, including 43kg of colorant, 12kg of color aid, 15kg of binder and 30kg of lubricant;

[0047] Pigments include 9.6kg cobalt oxide, 18.5kg manganese oxide, 1.2kg iron oxide, 51.6kg alumina, 8.9kg silica, 3.4kg zinc oxide, 6.8kg boric acid;

[0048]Color aids include 73.4kg silica, 15.6kg alumina, 2.8kg potassium oxide, 2.6kg sodium oxide and 5.6kg calcium oxide;

[0049] Binders include 95kg mud, 3kg polyethylene glycol and 2kg hydroxymethyl cellulose;

[0050] Lubricants include 80kg flake graphite and 20kg black talc;

[0051] The preparation method of above-mentioned underglaze color pigment, comprises the following steps,

[0052] The raw materials of the toner are mixed and calcined at 1270°C, and then crushed to a particle size of 1-5 μm for later use;

[0053] After mixing the raw materials of color auxiliaries, they are melted at a high temperature of 1420°C, quenched ...

Embodiment 2

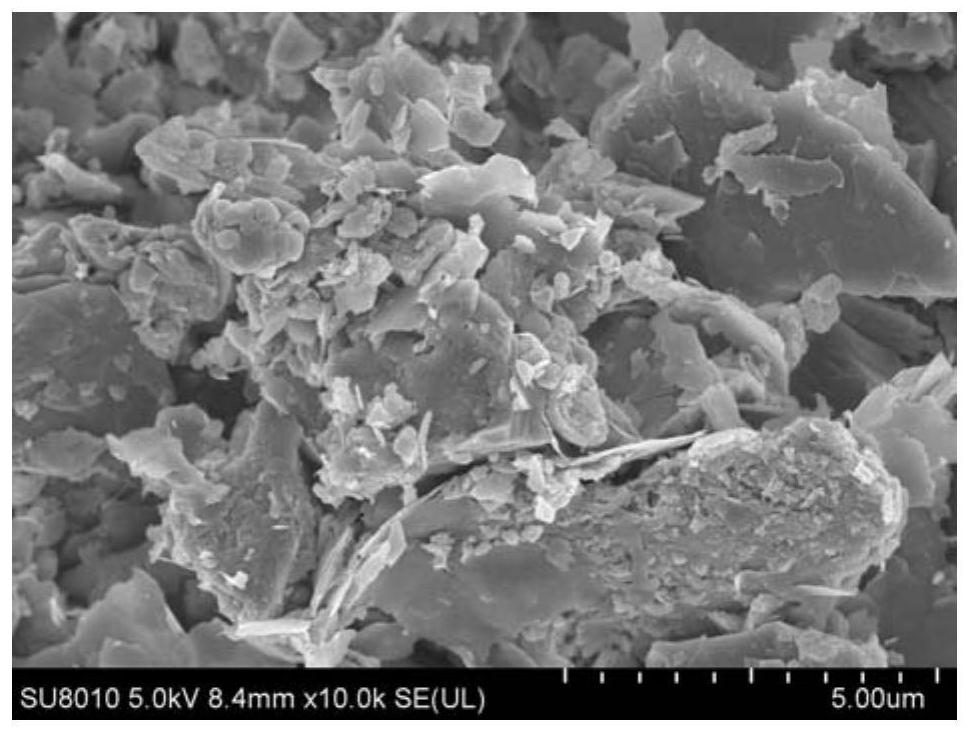

[0057] This embodiment provides an underglaze color pigment with a particle size of less than 3 μm, including 50kg of colorant, 8kg of color aid, 22kg of binder and 20kg of lubricant;

[0058] Pigments include 10.2kg cobalt oxide, 20.5kg manganese oxide, 1.4kg iron oxide, 50.1kg alumina, 7.8kg silica, 2.5kg zinc oxide, 7.5kg boric acid;

[0059] Color aids include 71.9kg of silica, 16.4kg of alumina, 2.6kg of potassium oxide, 2.1kg of sodium oxide and 7.0kg of calcium oxide;

[0060] The binder includes 87kg mud, 8kg polyethylene glycol and 5kg polyvinyl alcohol;

[0061] Lubricants include 80kg flake graphite, 5kg molybdenum disulfide and 15kg black talc;

[0062] The preparation method of above-mentioned underglaze color pigment, comprises the following steps,

[0063] The raw materials of the toner are mixed and calcined at 1280°C, and then crushed to a particle size of 1-5 μm for later use;

[0064] After mixing the raw materials of color auxiliaries, they are melted at...

Embodiment 3

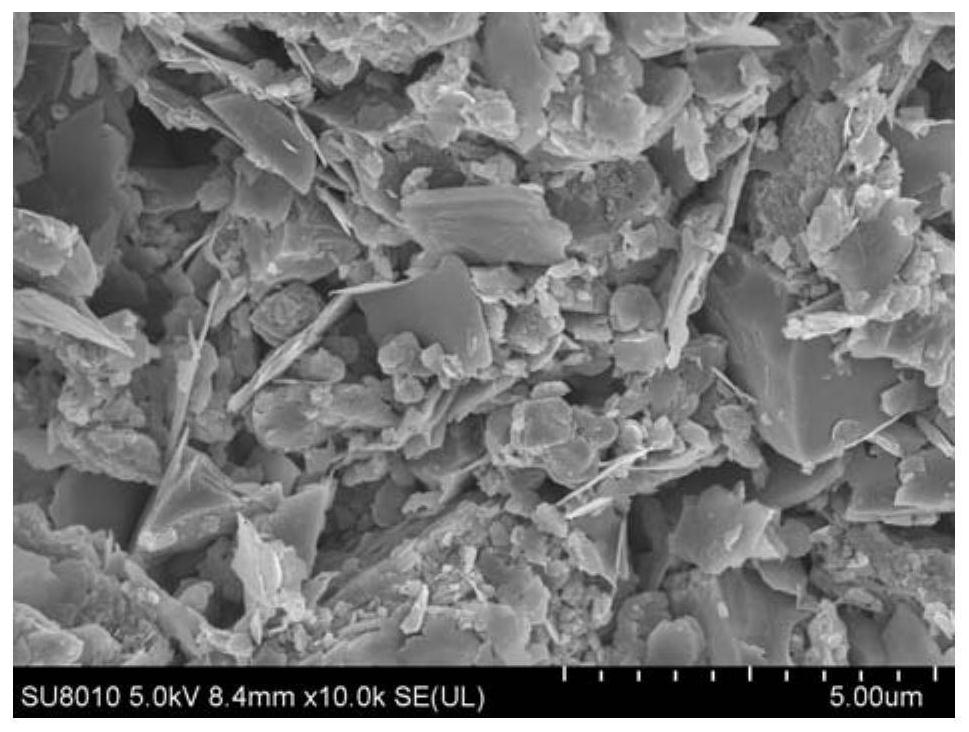

[0068] This embodiment provides an underglaze color pigment with a particle size of less than 3 μm, including 56kg of colorant, 15kg of color aid, 16kg of binder and 13kg of lubricant;

[0069] Pigments include 11.5kg cobalt oxide, 18.5kg manganese oxide, 1.6kg iron oxide, 49.6kg alumina, 8.3kg silica, 2.0kg zinc oxide, 8.5kg boric acid;

[0070] Color aids include 72.4kg silica, 15.2kg alumina, 3.2kg potassium oxide, 2.6kg sodium oxide and 6.6kg calcium oxide;

[0071] Binders include 80kg mud, 5kg polyethylene glycol and 15kg hydroxymethyl cellulose;

[0072] Lubricants include 75kg flake graphite, 20kg molybdenum disulfide and 5kg black talc;

[0073] The preparation method of above-mentioned underglaze color pigment, comprises the following steps,

[0074] The raw materials of the toner are mixed and calcined at 1270°C, and then crushed to a particle size of 1-5 μm for later use;

[0075] After mixing the raw materials of color auxiliaries, they are melted at a high tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com