Production method and production system of high-stability coal water slurry fuel

A high-stability, production-system technology, used in fuels, liquid carbon-containing fuels, petroleum industry, etc., can solve the problems of increasing fluidity, frequent tank cleaning, large sedimentation, etc. The effect of reducing the chance of bumping and increasing the chance of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

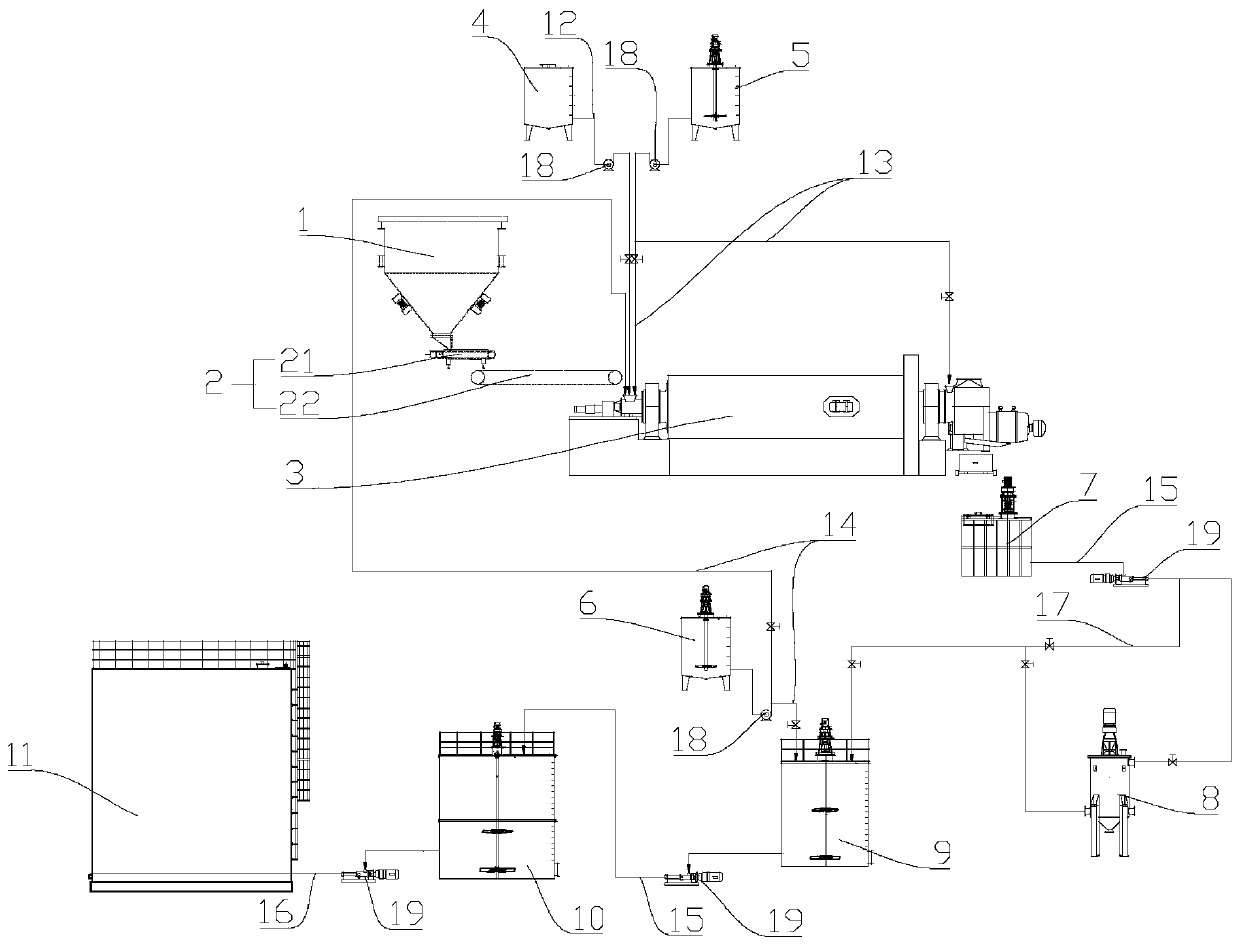

[0047] The production method of high-stability coal-water slurry fuel comprises the steps:

[0048] (1) Determine the total amount of dispersant and the total amount of stabilizer according to the total amount of raw coal and the slurry test data of raw coal;

[0049] (2) Add all raw coal, water, dispersant accounting for 60% of the total amount of dispersant and stabilizer accounting for 10% of the total amount of stabilizer from the inlet end of the mill 3 into the mill 3 for grinding;

[0050] (3) Add the remaining 40% of the dispersant from the outlet end of the mill 3 to the slurry flowing out from the outlet end of the mill 3 to obtain a primary slurry;

[0051] (4) After the primary slurry obtained in step (3) is collected, stirred and finely filtered, it is delivered to the stirring tank 9;

[0052] (5) Add the remaining 90% stabilizer to the stirring tank 9 and mix and stir evenly with the slurry in the stirring tank 9 to obtain a secondary slurry;

[0053] (6) Tran...

Embodiment 2

[0055] The production method of high-stability coal-water slurry fuel comprises the steps:

[0056] (1) Determine the total amount of dispersant and the total amount of stabilizer according to the total amount of raw coal and the slurry test data of raw coal;

[0057] (2) Add all raw coal, water, dispersants accounting for 70% of the total amount of dispersants and stabilizers accounting for 15% of the total amount of stabilizers from the inlet end of the mill 3 into the mill 3 for grinding;

[0058] (3) Add the remaining 30% dispersant from the outlet end of the mill 3 to the slurry flowing out from the outlet end of the mill 3 to obtain a primary slurry;

[0059] (4) After the primary slurry obtained in step (3) is collected, stirred and finely filtered, it is delivered to the stirring tank 9;

[0060] (5) Add the remaining 85% stabilizer to the stirring tank 9 and mix and stir evenly with the slurry in the stirring tank 9 to obtain a secondary slurry;

[0061] (6) Transpo...

Embodiment 3

[0063] The production method of high-stability coal-water slurry fuel comprises the steps:

[0064] (1) Determine the total amount of dispersant and the total amount of stabilizer according to the total amount of raw coal and the slurry test data of raw coal;

[0065] (2) Add all raw coal, water, dispersants accounting for 77% of the total amount of dispersants and stabilizers accounting for 20% of the total amount of stabilizers from the inlet end of the mill 3 into the mill 3 for grinding;

[0066] (3) Add the remaining 23% dispersant from the outlet end of the mill 3 to the slurry flowing out from the outlet end of the mill 3 to obtain a primary slurry;

[0067] (4) After the primary slurry obtained in step (3) is collected, stirred and finely filtered, it is delivered to the stirring tank 9;

[0068] (5) Add the remaining 80% stabilizer to the stirring tank 9 and mix and stir evenly with the slurry in the stirring tank 9 to obtain a secondary slurry;

[0069] (6) Transpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com