Prefabricated green building system and construction method thereof

A green building and prefabricated technology, which is applied in the direction of building construction and construction, can solve the problems of reducing the strength and stability of prefabricated buildings, and achieve the effects of improving the fixing effect, improving the sealing, and improving the strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings.

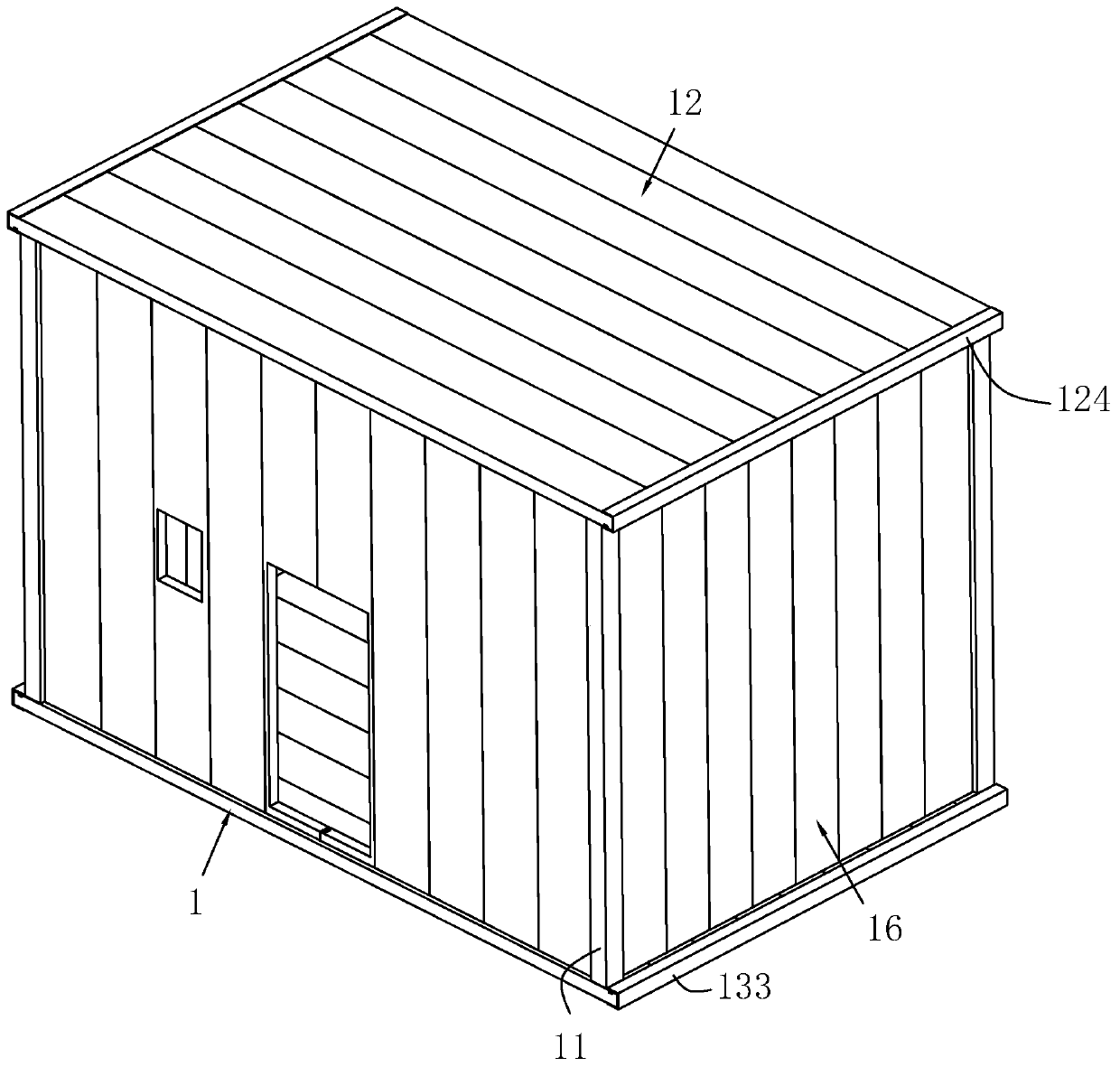

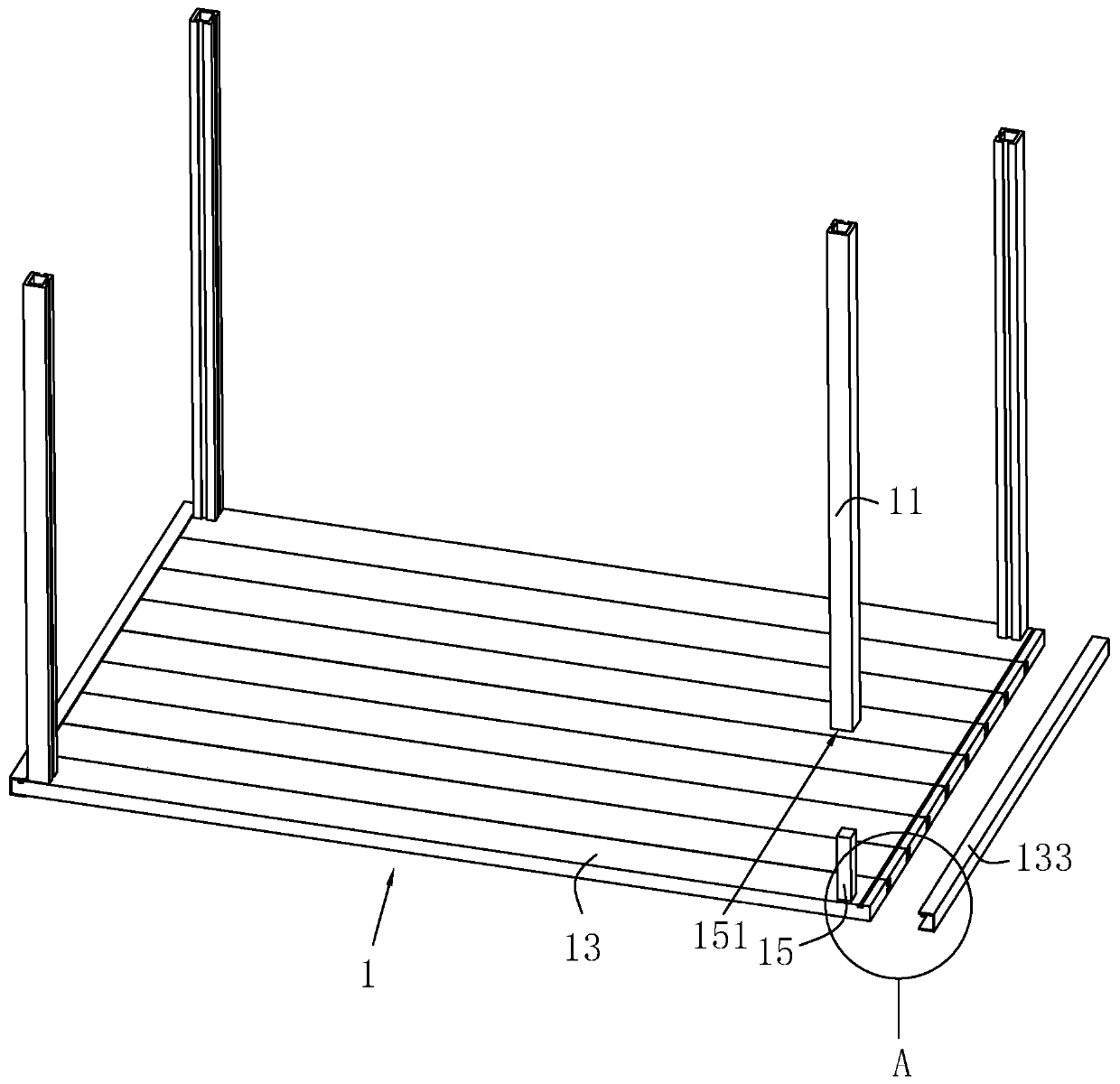

[0049] refer to figure 1 , is a prefabricated green building system disclosed in the present invention, comprising a base plate 1, on which columns 11 are arranged at the four corners of the base plate 1, side plates 16 are arranged between adjacent columns 11, and a plurality of columns 11 are far away from A top plate 12 is provided at the end of the bottom plate 1 .

[0050] combine figure 1 and figure 2 , in order to reduce the footprint of the entire bottom plate 1 and facilitate the transportation of the bottom plate 1 , the bottom plate 1 includes a plurality of first splicing strips 13 formed by splicing each other.

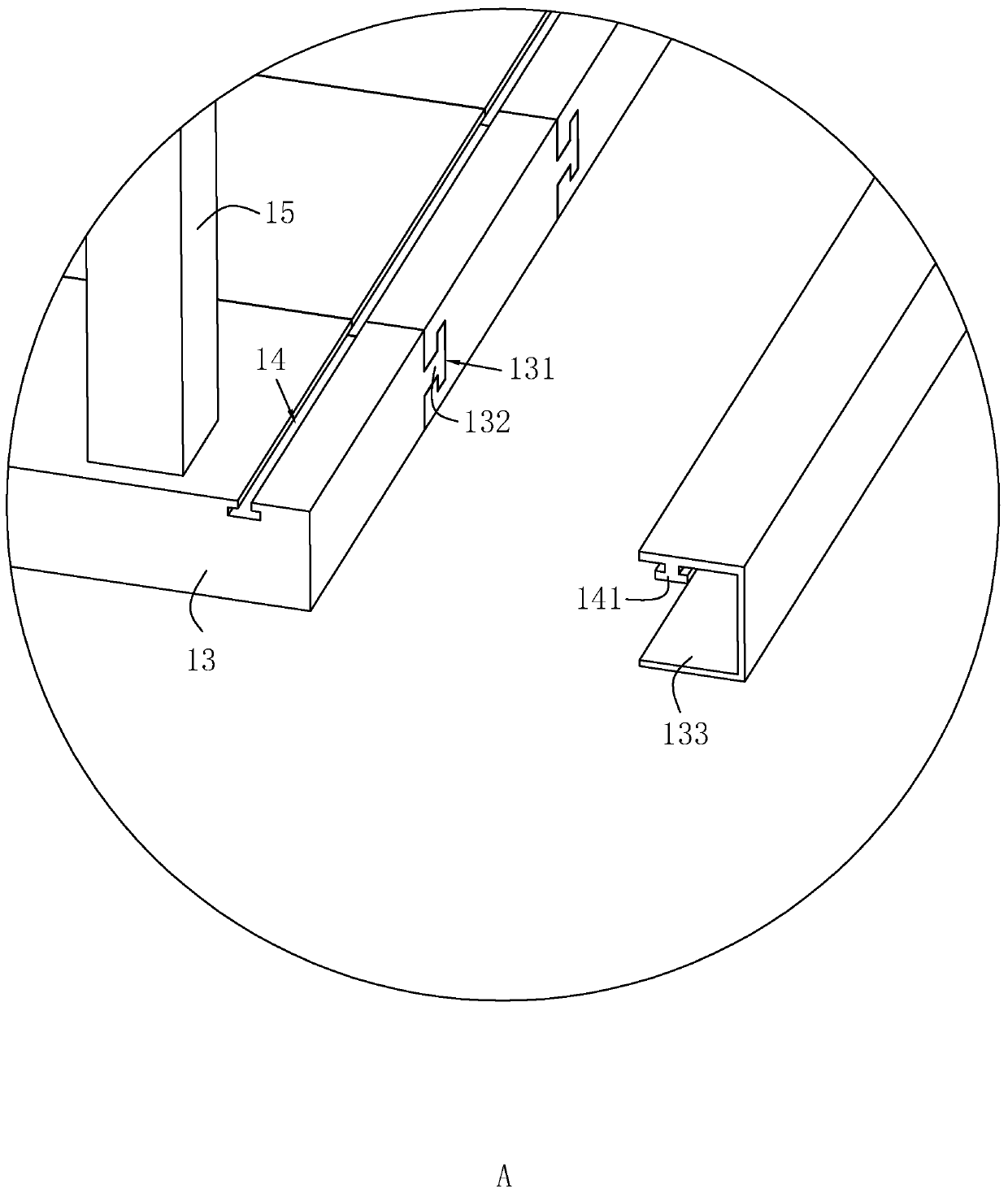

[0051] combine figure 2 and image 3 In order to fix the adjacent first splicing strips 13 together, a first slot 131 and a first inserting strip 132 that cooperate with each other are provided on the opposite surfaces of the adja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com