Power transmission tower angle steel reinforcing device

A technology for strengthening devices and transmission towers, which is applied in towers, building maintenance, building types, etc., can solve the problems of increased brittleness of main materials, weakened strength of main materials, easy cracking of main materials of angle steel, etc., to achieve increased strength, convenient construction and operation, Avoid the effect of strength destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical scheme of the present invention will be further described below in conjunction with the drawings.

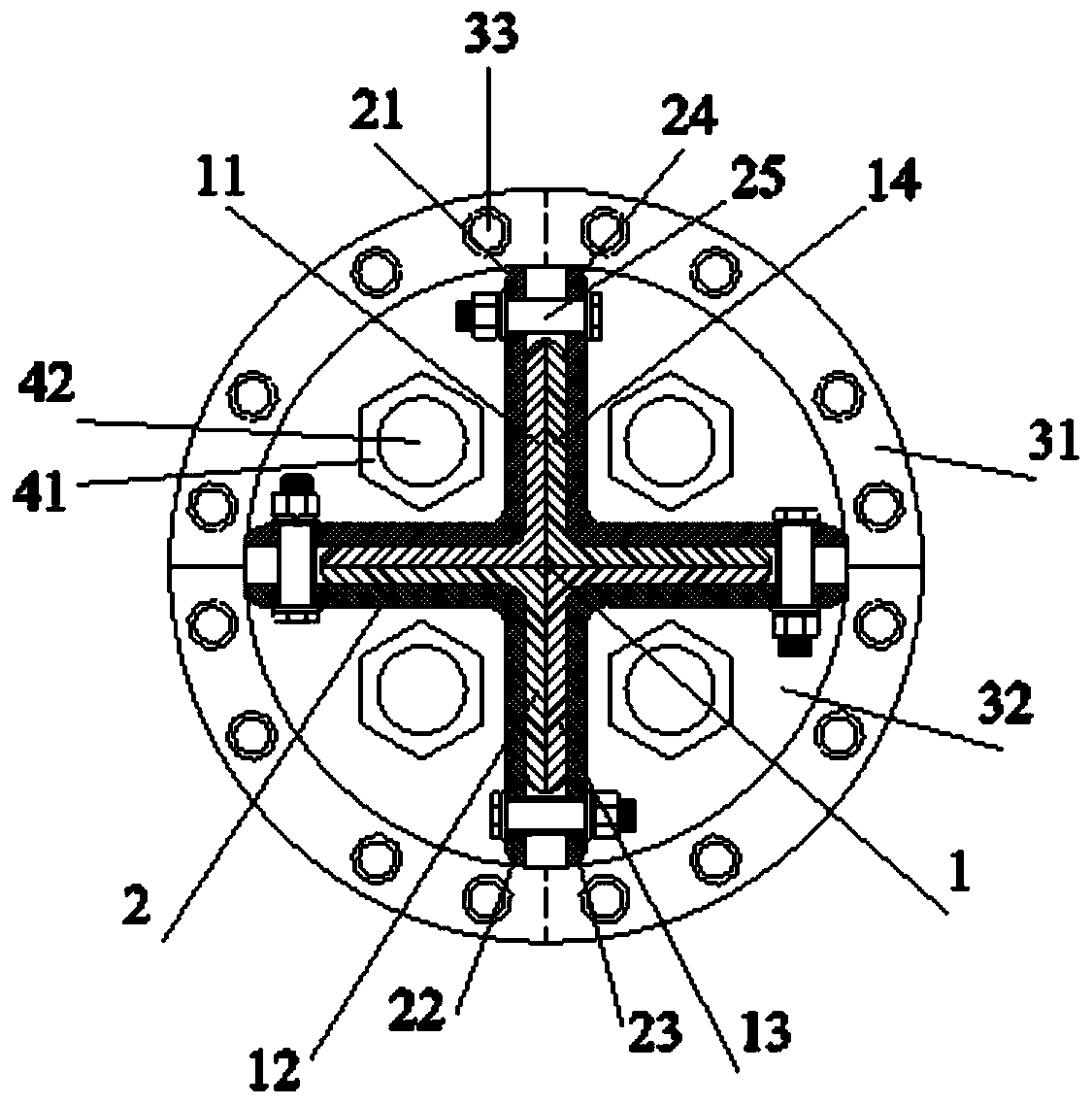

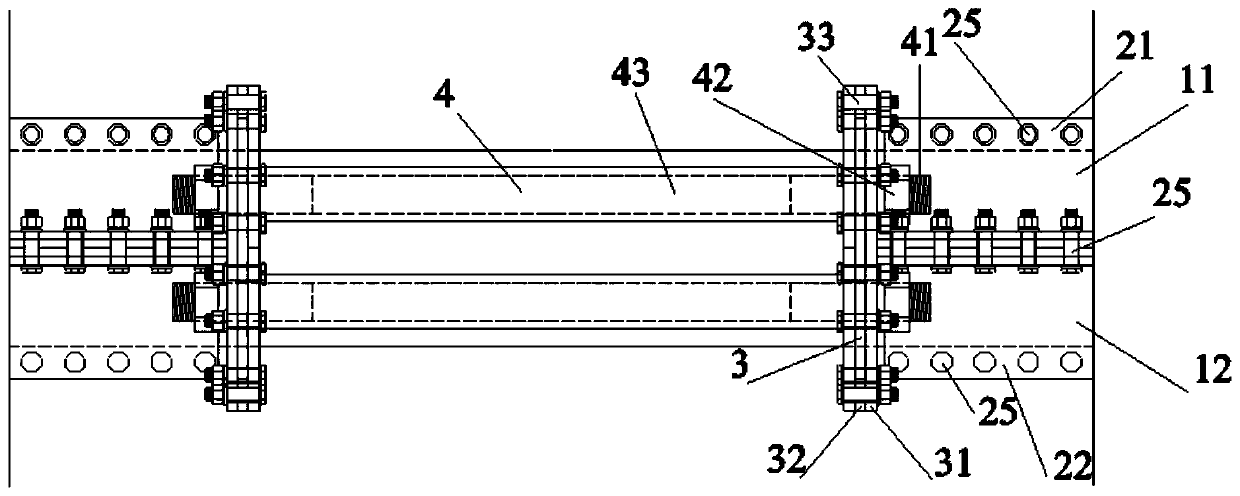

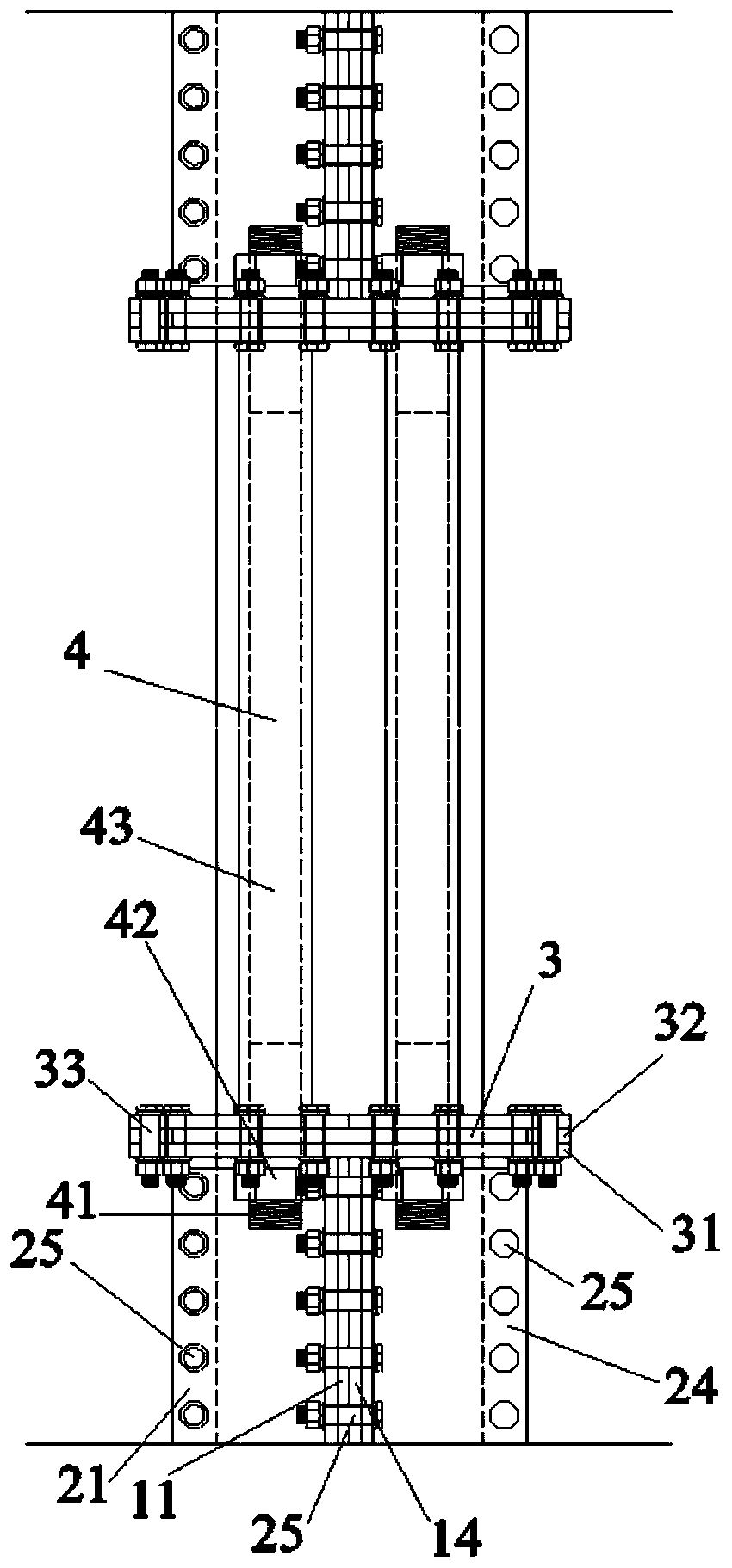

[0028] Such as Figure 1 to Figure 7 As shown, a transmission tower angle steel reinforcement device includes a first reinforcement angle steel 12, a second reinforcement angle steel 13, and a third reinforcement angle steel 14 having the same cross-section as the transmission tower main material 11. The transmission tower main material 11 and the first reinforcing angle steel 12, the second reinforcing angle steel 13, and the third reinforcing angle steel 14 are spliced into a cross-shaped structure 1;

[0029] The cross-section of the cross-shaped structure 1 forms four quadrants according to the plane coordinate system. The end of the cross-shaped structure 1 is connected to a reinforcing member 2, and the reinforcing member 2 includes: the surface of each quadrant is attached to a reinforcing angle steel , The right-angle sides of the reinforced angles 21,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com