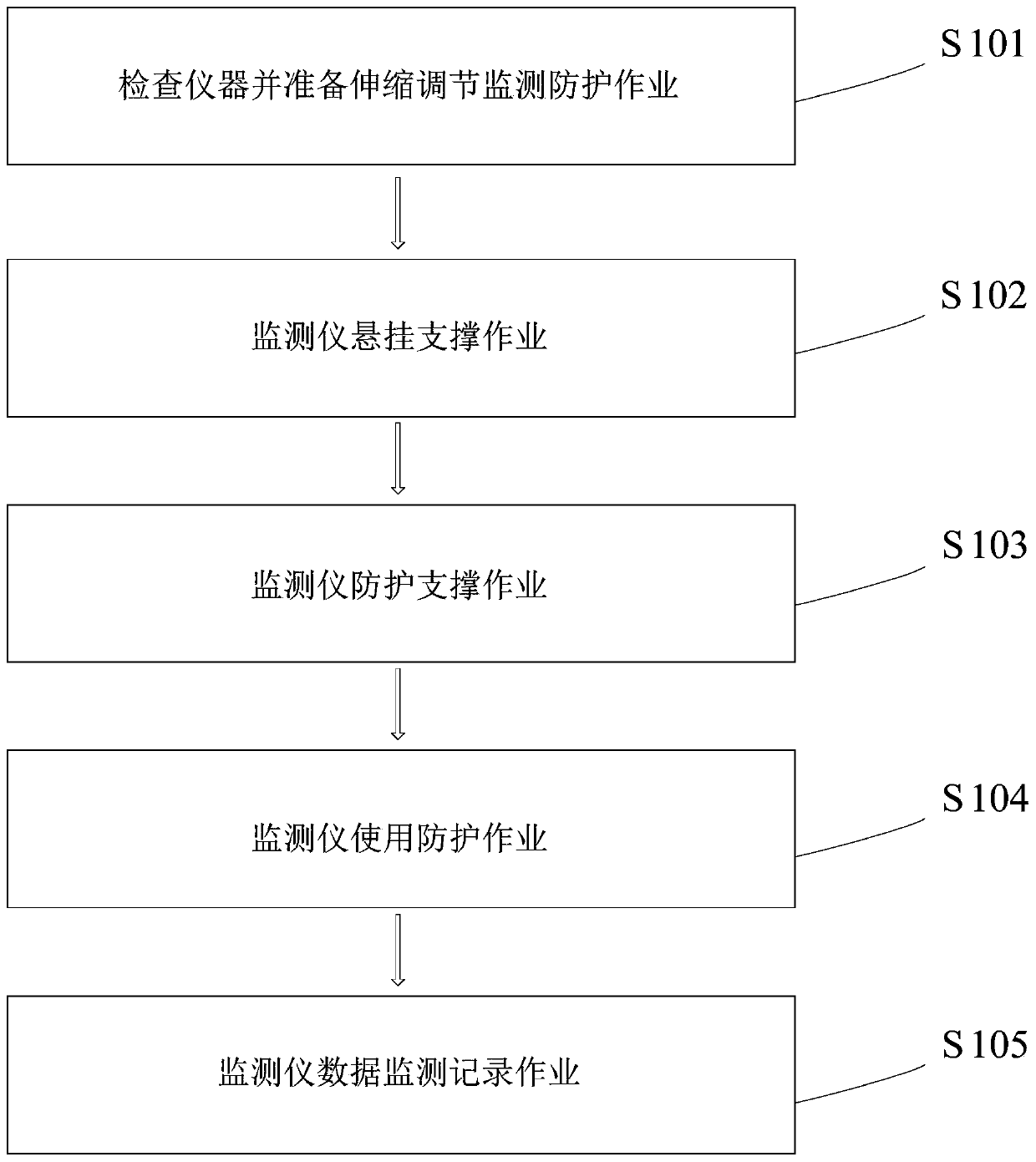

Multi-channel gas parameter monitor and use method thereof

A parameter monitoring, multi-channel technology, used in instruments, fuel testing, measuring devices, etc., can solve the problems of lack of bottom support protection function, inconvenience to record monitoring data, easy to be affected by dust and coal dust, etc. Dust influence, easy to monitor the effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

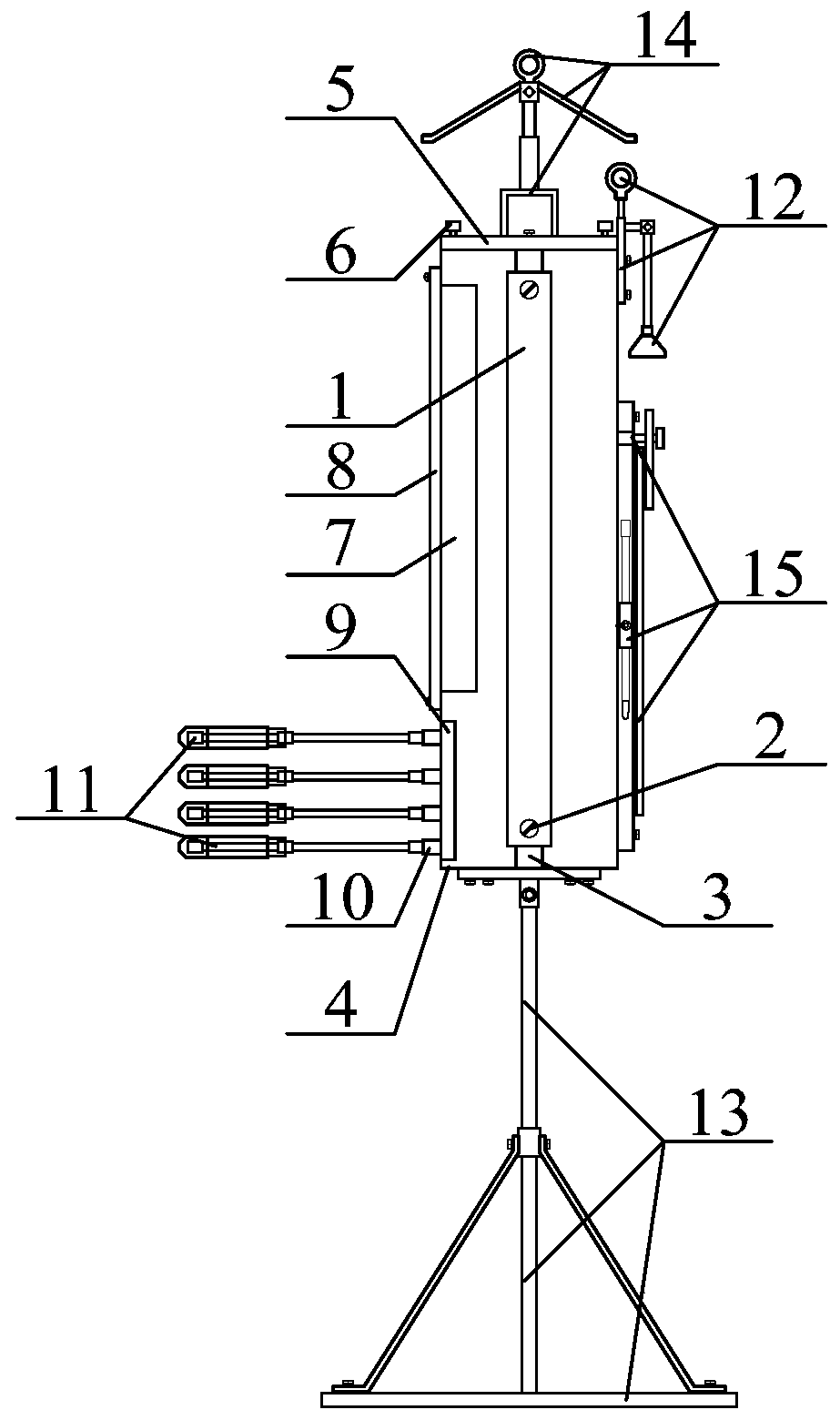

[0046] The present invention will be further described below in conjunction with accompanying drawing:

[0047] In the picture:

[0048] as attached figure 2 to attach Figure 8 shown

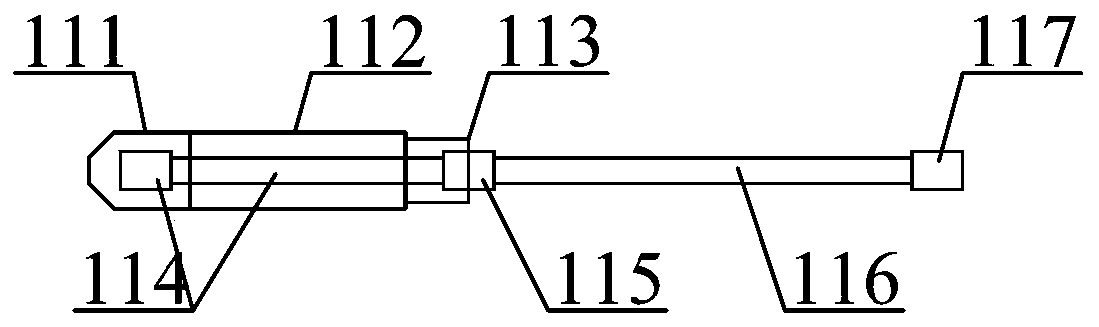

[0049] A multi-channel gas parameter monitor, including a host 1, mounting screws 2, mounting plate 3, detector main shell 4, dismounting plate 5, connecting bolts 6, monitoring data panel 7, transparent protective sheet 8, and multi-channel adapter plate 9. Data acquisition channel 10, protective telescopic adjustable monitoring probe protective cover structure 11, suspendable auxiliary support ring structure 12, bottom protective detachable frame structure 13, detachable portable protective umbrella structure 14 and replaceable monitoring data Recording board structure 15, the host 1 is installed longitudinally at the front middle position of the mounting plate 3 through the mounting screws 2; the mounting plate 3 is longitudinally arranged at the inner middle position of the main casing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com