Reciprocating pump facilitating leakage detection

A reciprocating pump and leak detection technology, which is applied in the field of reciprocating pumps, can solve the problems of long single well operation time and frequent construction operations, and achieve the effects of easy maintenance, enhanced sealing, and tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

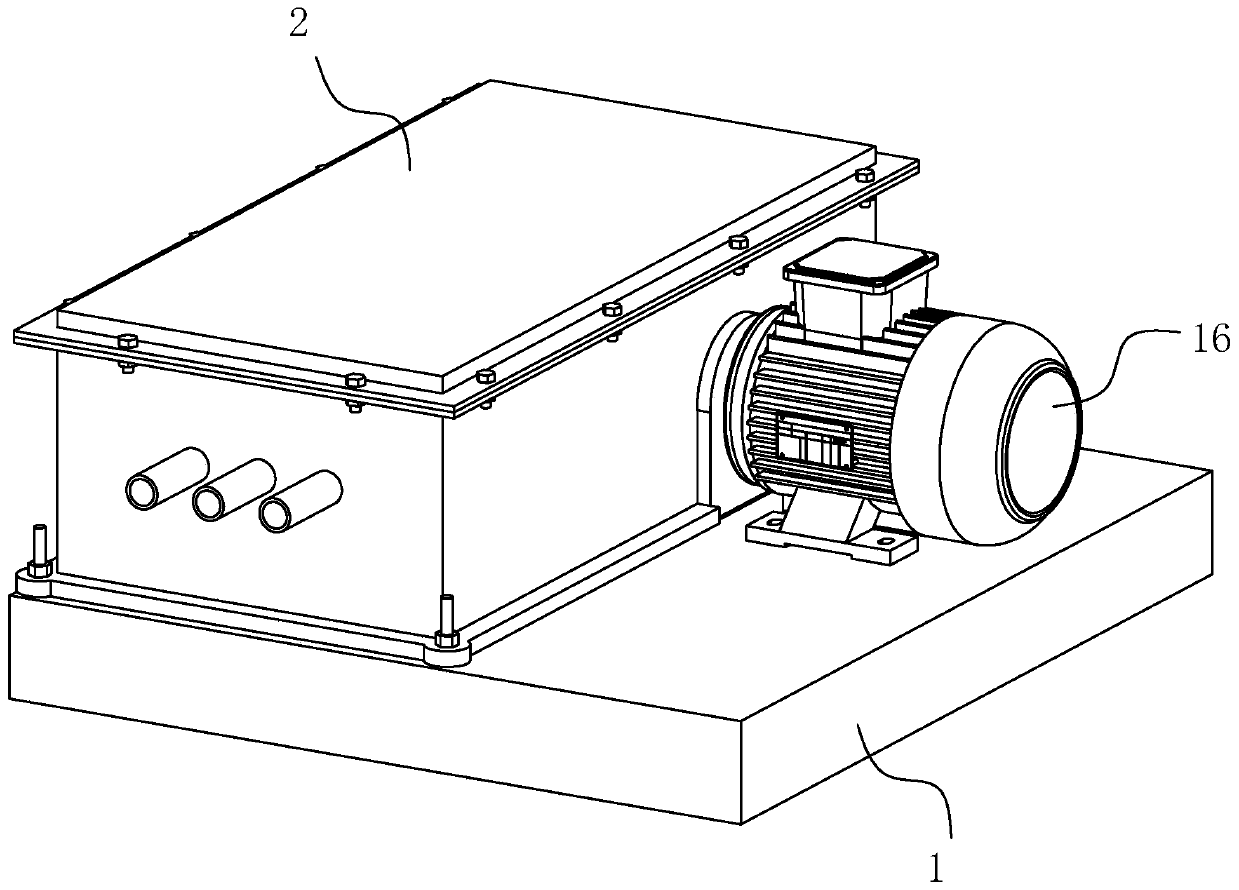

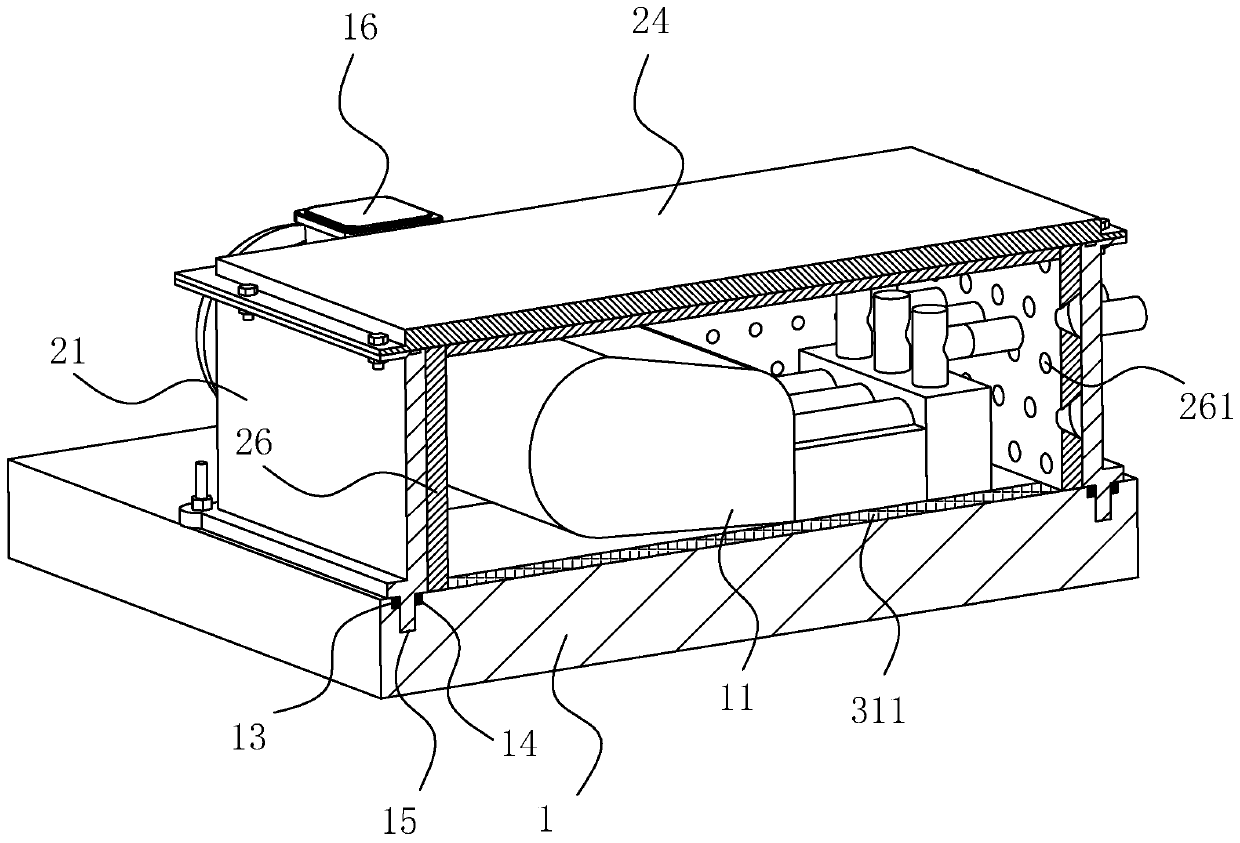

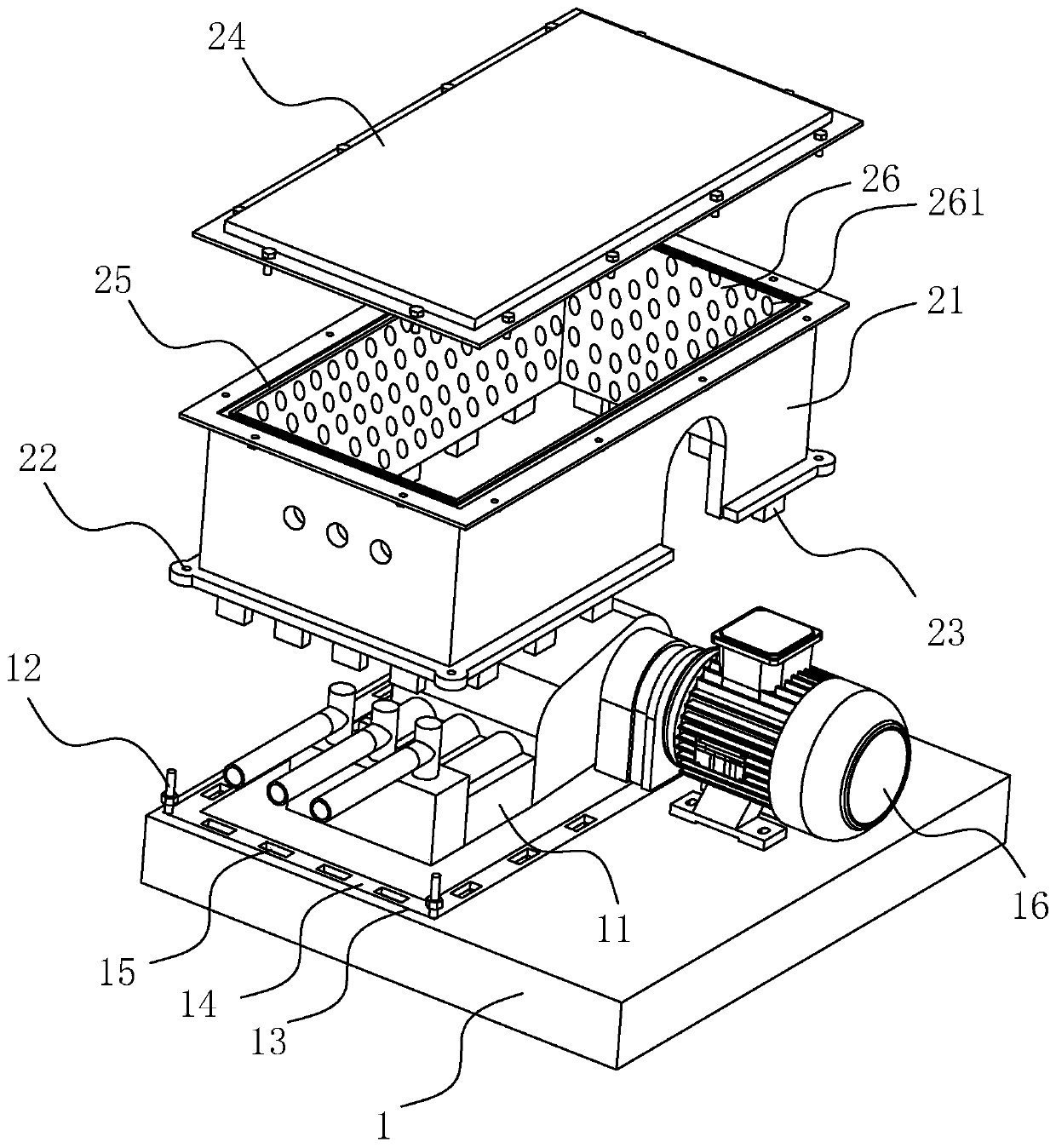

[0035] A reciprocating pump that is easily leak tested, see figure 1 and figure 2 , including a base 1, a pump body 11 is fixed on the top of the base 1, and the base 1 is located outside the pump body 11 and is detachably connected with a sealing cover 2 covering the pump body 11, and the sealing cover 2 keeps the pump body 11 in an airtight condition Next, the pump body 11 is connected with a detection device 3 for detecting whether the pump body 11 leaks. The base 1 is located outside the sealing cover 2 and is fixed with a motor 16 whose output shaft extends into the sealing cover 2. The motor 16 is used to drive the pump body The valve rod of 11 reciprocates.

[0036] see figure 2 and image 3The sealing cover 2 includes a cover body 21, the four corners of the base 1 corresponding to the cover body 21 are fixed on the vertically arranged screw rod 12, the four corners of the cover body 21 are provided with through holes 22, and the through holes 22 are used for supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com