Load-bearing cylinder main support structure of large off-axis three-mirror space remote sensing camera

An off-axis three-mirror, remote sensing camera technology, applied in the field of space optical remote sensing, can solve the problems of excessive size envelope and low support stiffness, and achieve the effects of reducing mass, improving Y-direction stiffness, and reducing the size of the outer envelope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

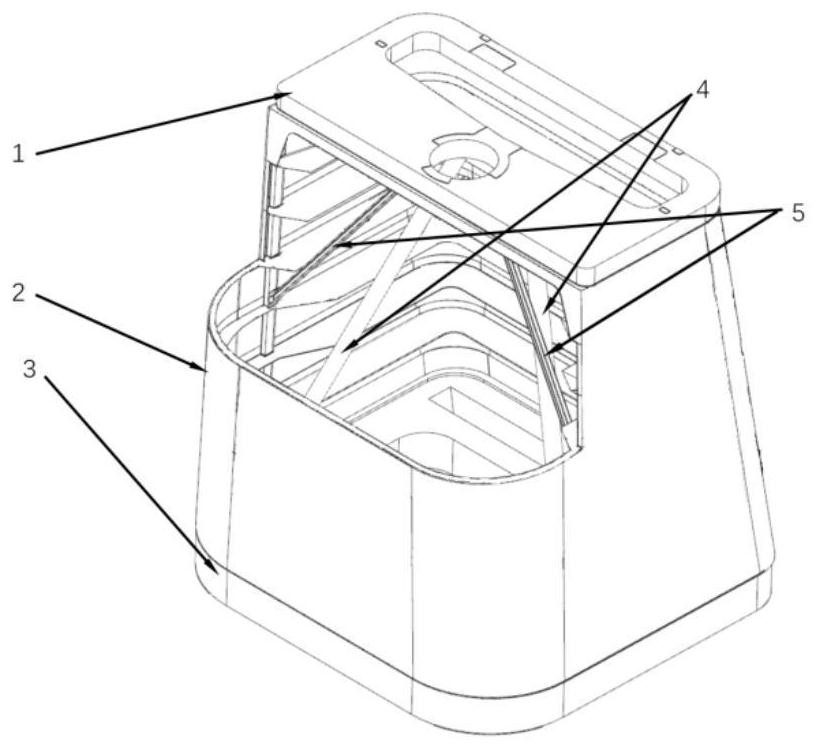

[0024] Specific implementation mode 1. Combination Figure 1 to Figure 8 In this embodiment, the load-bearing cylinder main support structure of a large off-axis three-mirror space remote sensing camera includes a front frame 1 , a main load-bearing cylinder 2 , a rear frame 3 , a truss rod assembly 4 and a rib assembly 5 . The main load-bearing cylinder 2 is connected with the front frame 1 and the rear frame 3 by screws; the truss rod assembly 4 includes two symmetrically arranged truss rods, the upper end of each truss rod is positioned and connected with the front frame, and each truss rod The lower end is positioned and connected to the rear frame; the lower end of the rib assembly 5 is connected to the main load-bearing cylinder and the upper end of the rib assembly 5 is connected to the front frame 1 with a titanium alloy joint;

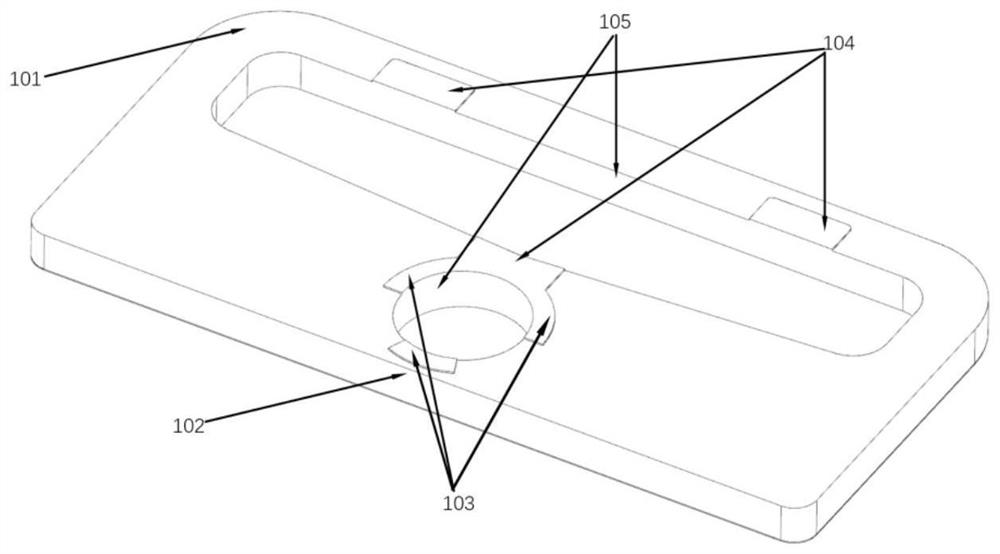

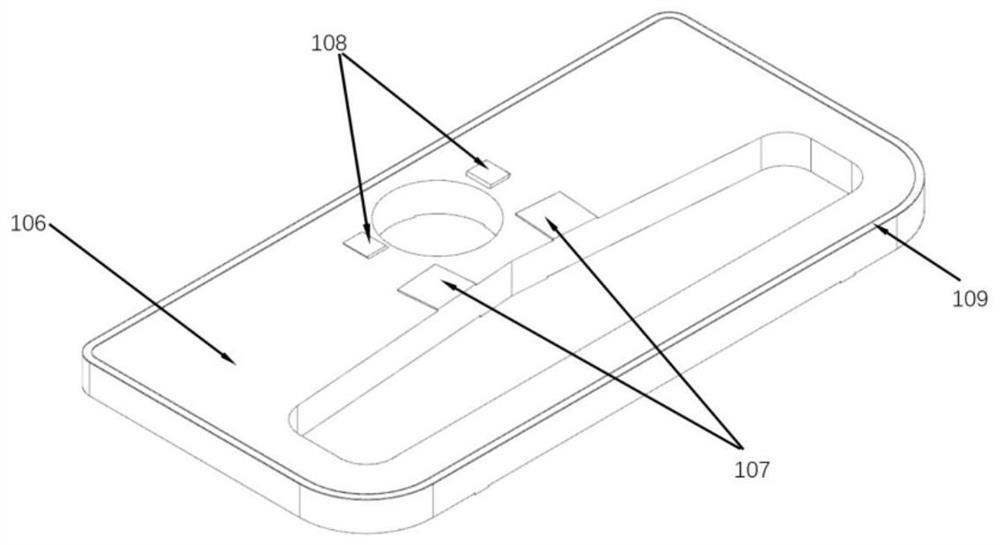

[0025] combine figure 2 and image 3 To illustrate this embodiment, the main structure of the front frame 1 includes: the front frame uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com