Water source type high-temperature heat pump with adjustable outlet water temperature and temperature adjusting method thereof

A heat pump technology with outlet water temperature and high temperature, applied in the field of HVAC, can solve the problems of lack of functionality at medium and low temperatures, and achieve the effects of slowing down global warming, saving carbon/sulfur/particulate matter emissions, and enhancing universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

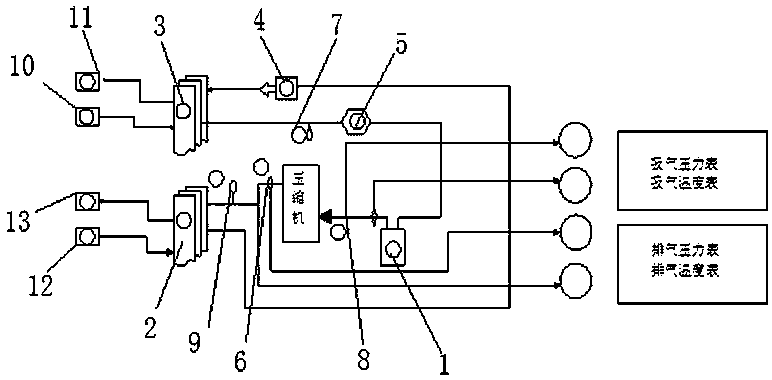

[0029] Embodiment 1: A water source type high temperature heat pump with adjustable outlet water temperature, such as Figure 1-2 As shown, it includes an oil-gas separator 1, the upper end of the oil-gas separator 1 is connected with the low-pressure side sensor 8 and the compressor, and the other end of the working medium filter 5 is connected with a low-pressure side needle valve 7, and the low-pressure needle valve The other end of 7 is connected to an evaporator 3, which is a metal round basin with an inner diameter of φ200 mm and a height of about 100 mm. A heat source side feed water 10 is provided, and the output end of the heat source side feed water 10 is connected to the input end of the evaporator 3 .

[0030] The left end of the compressor is connected with a high-pressure side sensor 6, and the end of the high-pressure side sensor 6 far away from the compressor is connected with a high-pressure side needle valve 9 for adjusting the adaptability of the working flu...

Embodiment 2

[0046] A water-source high-temperature heat pump with adjustable outlet water temperature, such as Figure 1-2 As shown, it includes an oil-gas separator 1, the upper end of the oil-gas separator 1 is connected to the compressor through the low-pressure side sensor 8, and the other end of the working medium filter 5 is connected to the low-pressure side needle valve 7, and the low-pressure side The other end of the needle valve 7 is connected to the evaporator 3 (used to absorb the sensible heat of the water body, and the evaporator corresponds to a plate or shell-and-tube heat exchanger), and the output end of the evaporator 3 is connected to the heat source side outlet water 11, so The lower end of the heat source side outlet water 11 is provided with a heat source side inlet water 10 , and the output end of the heat source side inlet water 10 is connected to the input end of the evaporator 3 .

[0047]The left end of the compressor is connected to a high-pressure side senso...

Embodiment 3

[0056] A water-source high-temperature heat pump with adjustable outlet water temperature, such as Figure 1-2 As shown, it includes an oil-gas separator 1, the upper end of the oil-gas separator 1 is connected to the compressor through the low-pressure side sensor 8, and the other end of the working medium filter 5 is connected to the low-pressure side needle valve 7, and the low-pressure side The other end of the needle valve 7 is connected to an evaporator 3, the output end of the evaporator 3 is connected to a heat source side water outlet 11, and the lower end of the heat source side water outlet 11 is provided with a heat source side water inlet 10, and the heat source side water inlet 10 The output terminal is connected with the input terminal of the evaporator 3 .

[0057] The left end of the compressor is connected to a high-pressure side sensor 6, and the end of the high-pressure side sensor 6 far away from the compressor is connected to a high-pressure side needle v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com