Open air-cooled low-temperature refrigeration house for recovering cold energy of liquefied natural gas

A technology of liquefied natural gas and low-temperature cold storage, which is applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of complex refrigeration system, affect the temperature field of cold room, consume large electric energy, etc., and achieve simple system equipment, initial investment and low cost. The effect of less energy consumption and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

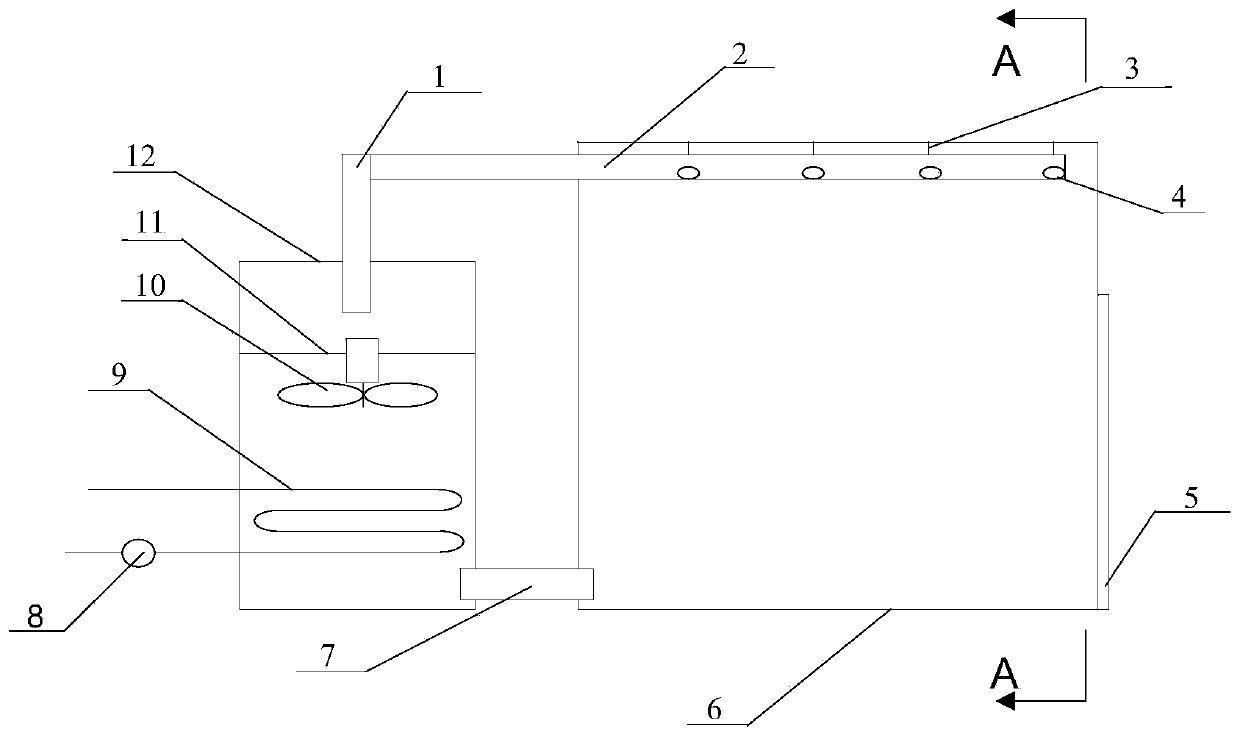

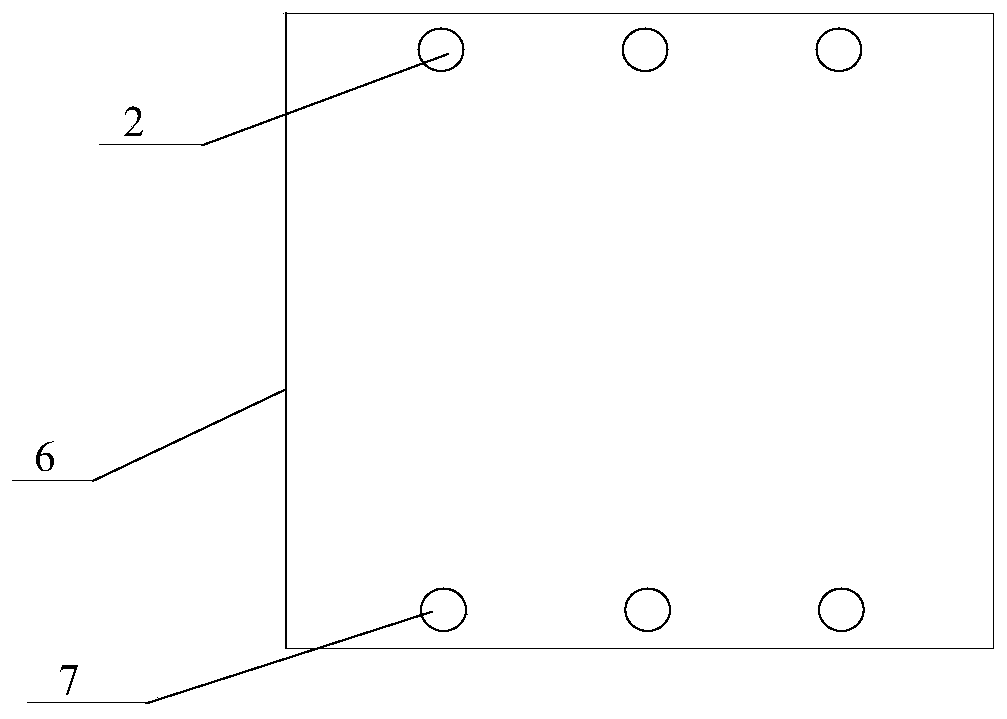

[0016] figure 1 and figure 2 As shown, the open air refrigeration low-temperature cold storage for recovering the cold energy of liquefied natural gas in the present invention includes a vertical air supply pipe 1, a horizontal air supply pipe 2, an air pipe hanger 3, an air outlet 4, a storage door 5, and a storage body 6 , return air pipe 7, liquefied natural gas pump 8, heat exchanger 9, fan 10, support 11, cold air treatment box 12.

[0017] One end of the vertical air supply pipe 1 goes deep into the top of the cold air treatment box 12, and the other end is connected with the horizontal air supply pipe 2, and the horizontal air supply pipe 2 is horizontally positioned at the top of the storehouse body and passes through the wall hole of the storehouse body The mouth is fixedly connected to the top of the storage body through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com