Universal multi-view workpiece flaw disc type inspection machine based on multi-color light source

An inspection machine, disc-type technology, applied in optical testing for flaws/defects, material analysis by optical means, measuring devices, etc., can solve the problem of poor versatility of optical inspection equipment, product diversity and multi-color inspection, fading, etc. problems, to achieve the effect of improving the versatility of equipment and the effective utilization of equipment, high practicability and promotion value, and reducing the cost of manufacturing enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

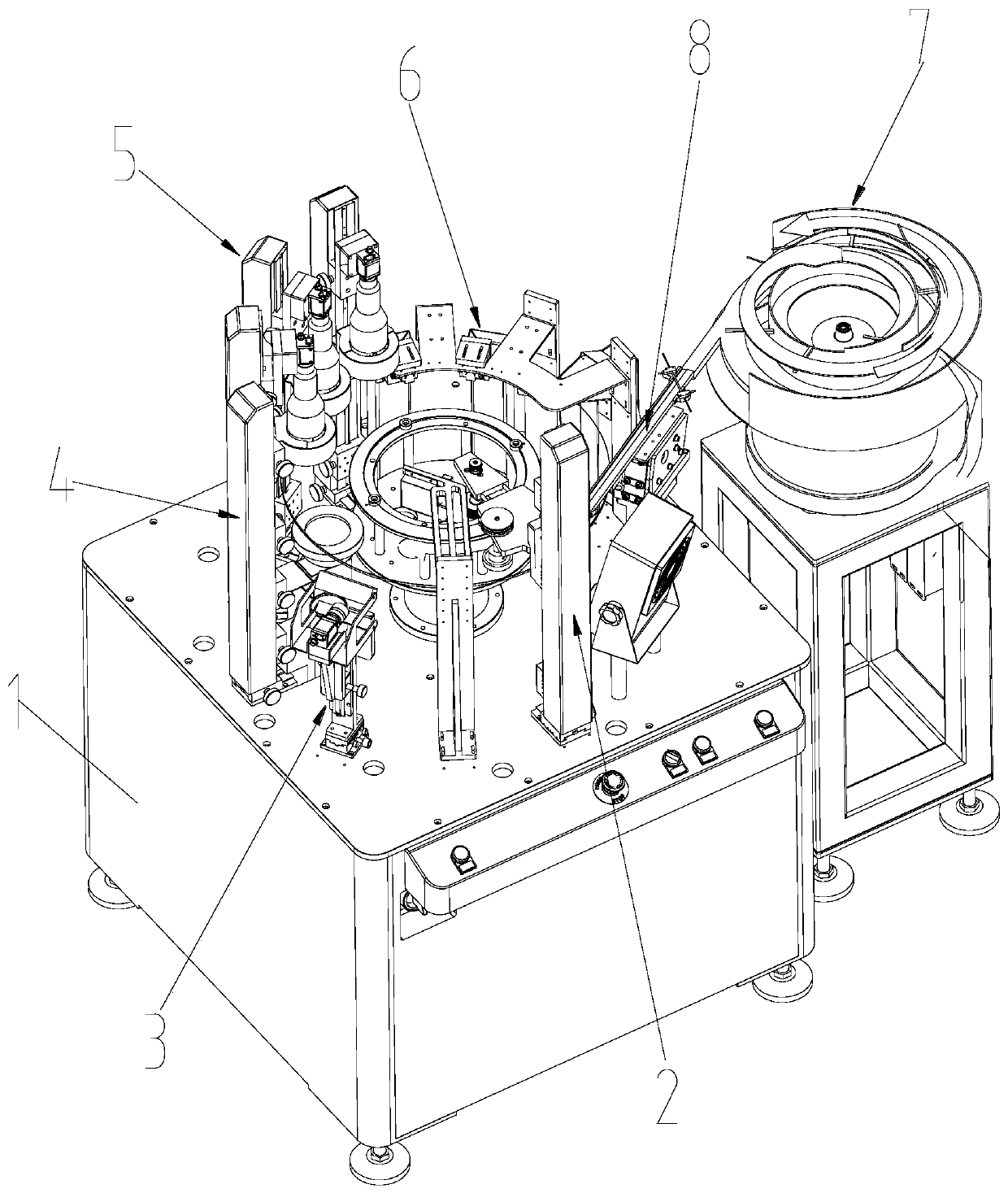

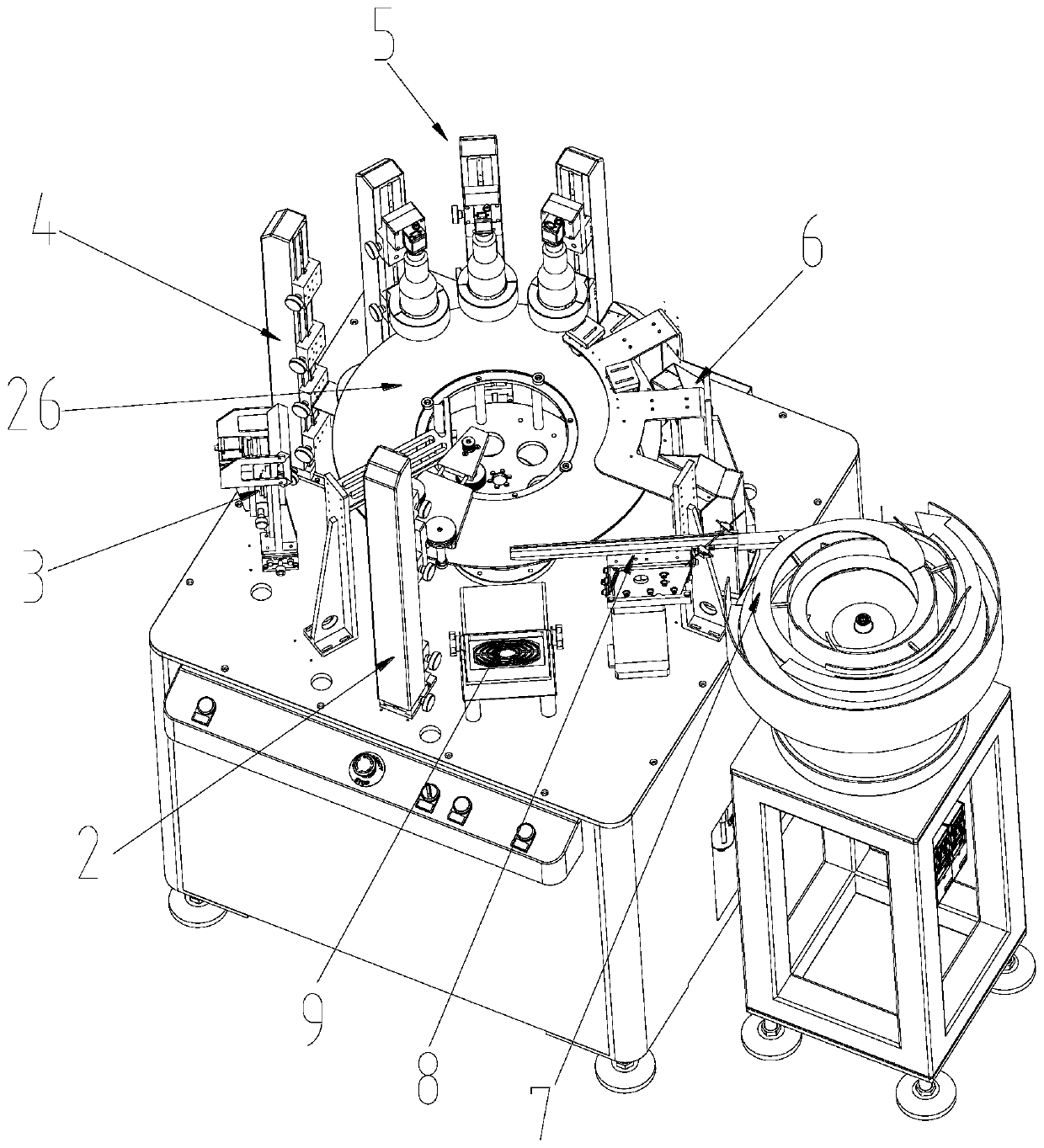

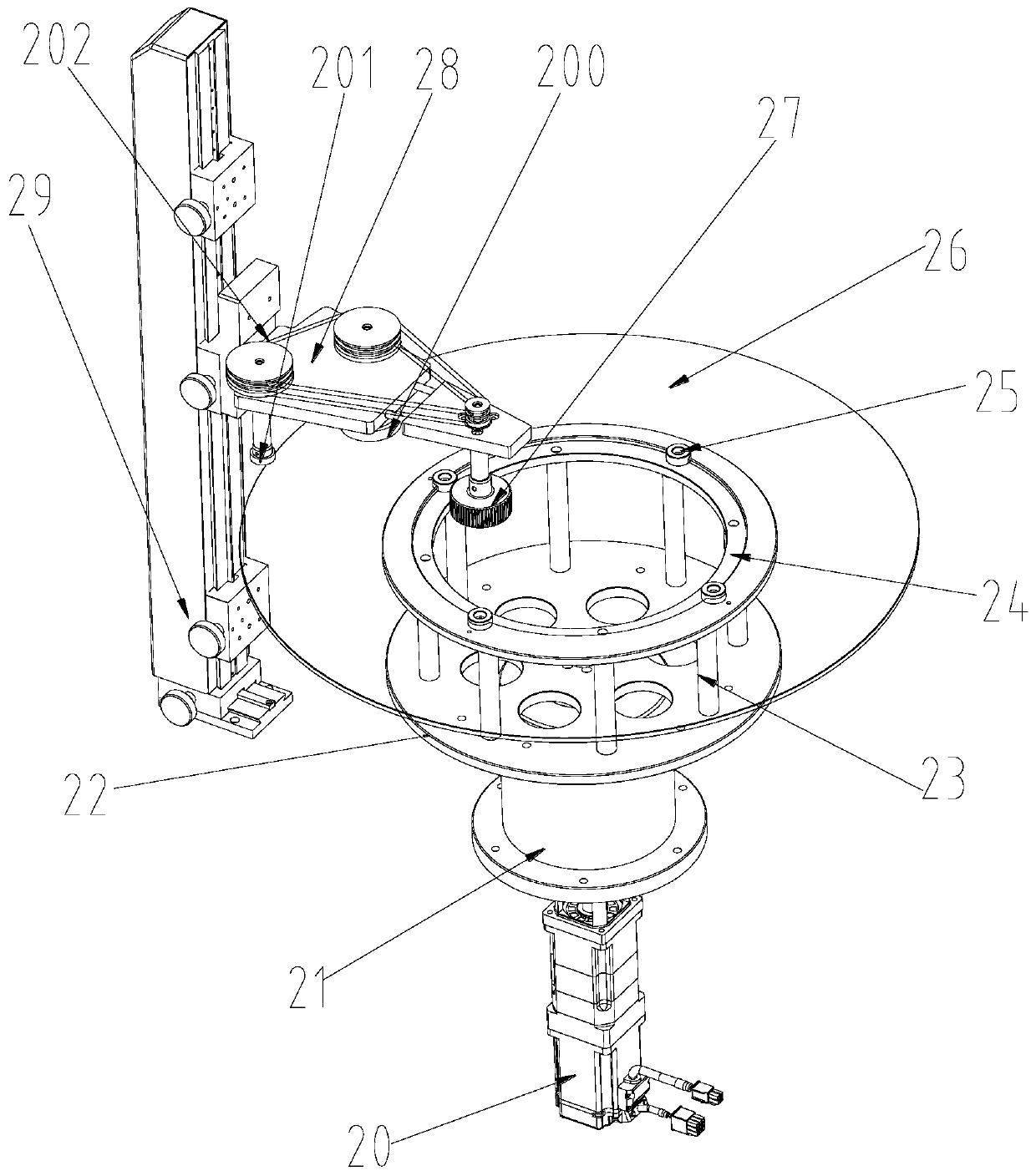

[0031] Please refer to the attached Figure 1-2 , shows a kind of multi-color light source-based general-purpose multi-view workpiece defect disc inspection machine according to the present invention, which includes a product rotary pre-guiding assembly 2 installed on the equipment rack 1 for inspecting the product Positioning and rotating; one side of the product rotary pre-guiding assembly 2 is provided with a linear vibrating plate assembly 8 and a circular vibrating plate assembly 7, which are used to feed the product into the product rotary pre-guiding assembly 2 ; Around the product rotary pre-guiding assembly 2, there are successively provided: product side detection station 3, which is used to detect the side of the product; product bottom surface detection station 4, which is used to detect the bottom surface of the product; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com