A FBG two-dimensional acceleration sensor based on U-shaped groove structure and its measurement method

An acceleration sensor, U-shaped groove technology, applied in multi-dimensional acceleration measurement, speed/acceleration/impact measurement, acceleration measurement using inertial force, etc., can solve the problem of large structure size, operating frequency range, large sensitivity difference, sensor sensitivity Small and other problems, to achieve the effect of simple structure, improved sensitivity and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

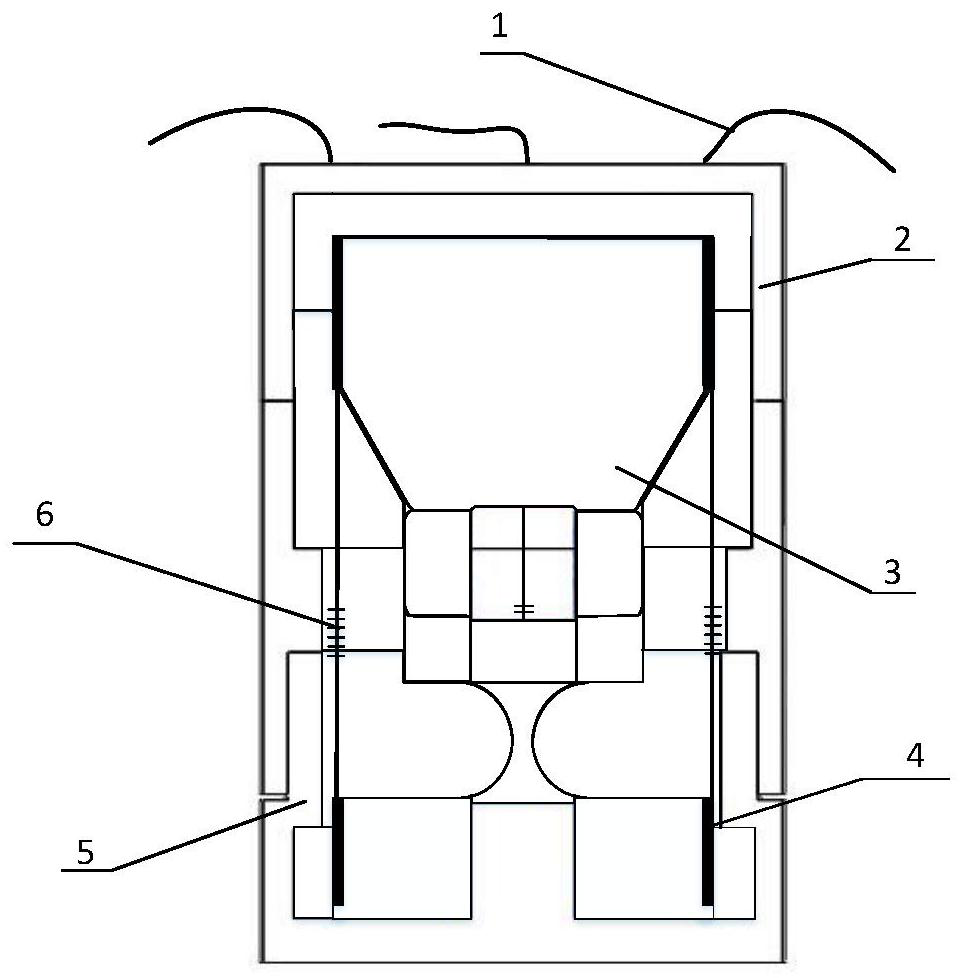

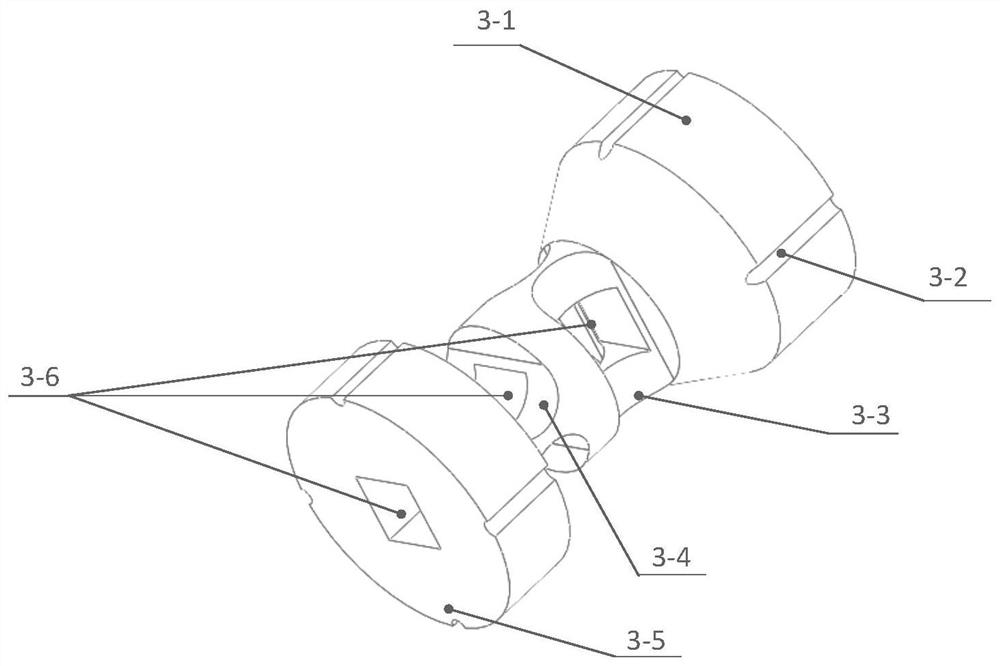

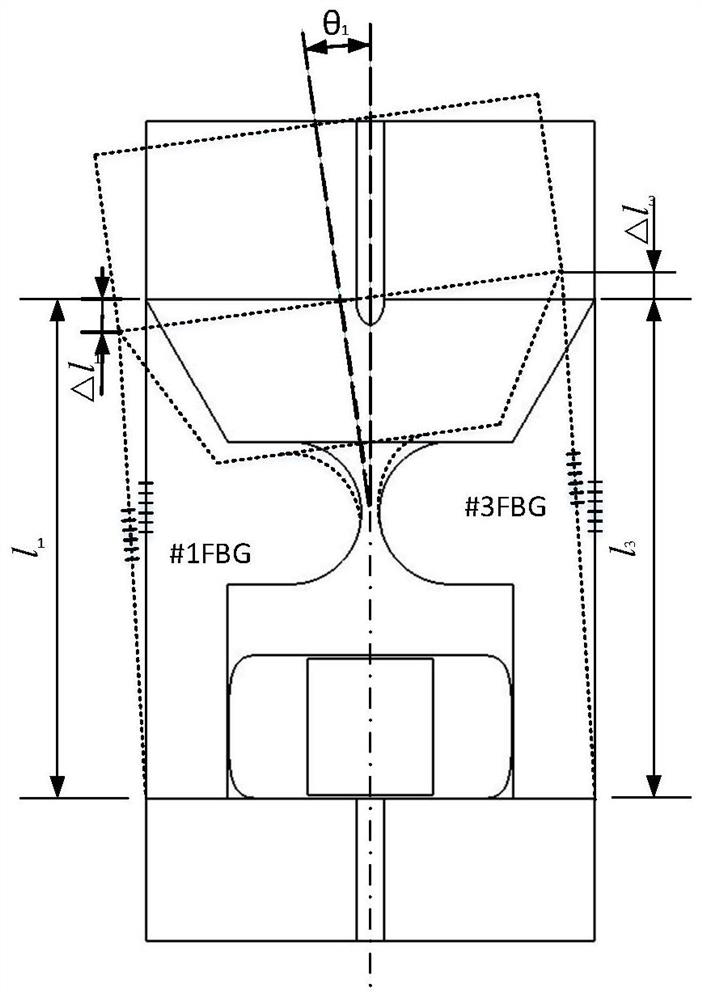

[0020] Below by embodiment, in conjunction with accompanying drawing, the technical scheme of the present invention is described further specifically, as Figure 1-6 As shown, a FBG two-dimensional acceleration sensor based on a U-shaped groove structure includes an upper shell 2 and a lower shell 5, a core 3 located in the middle of the upper and lower shells, and several optical fibers and gratings. The upper inertial body 3-1, the middle body and the lower base 3-5, the middle body of the core body 3 are provided with two pairs of U-shaped groove structures facing away from each other up and down, the opening directions of the upper and lower pairs of U-shaped grooves are vertical, and the base 3-5 and the upper and lower two pairs of U-shaped grooves have a vertically arranged square through hole 3-6 at the axis positions, and the lower housing 5 passes through the rectangular column on its internal axis and the square hole 3-6 in the base 3-5. 6 Cooperate and fix, the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com