Modeling and calculation method for flow channel of main pump of fast reactor based on virtual valve

A flow channel and model calculation technology, applied in simulators, general control systems, instruments, etc., can solve the problems of simplified and inaccurate simulation of fluid flow characteristics, etc., and achieve the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

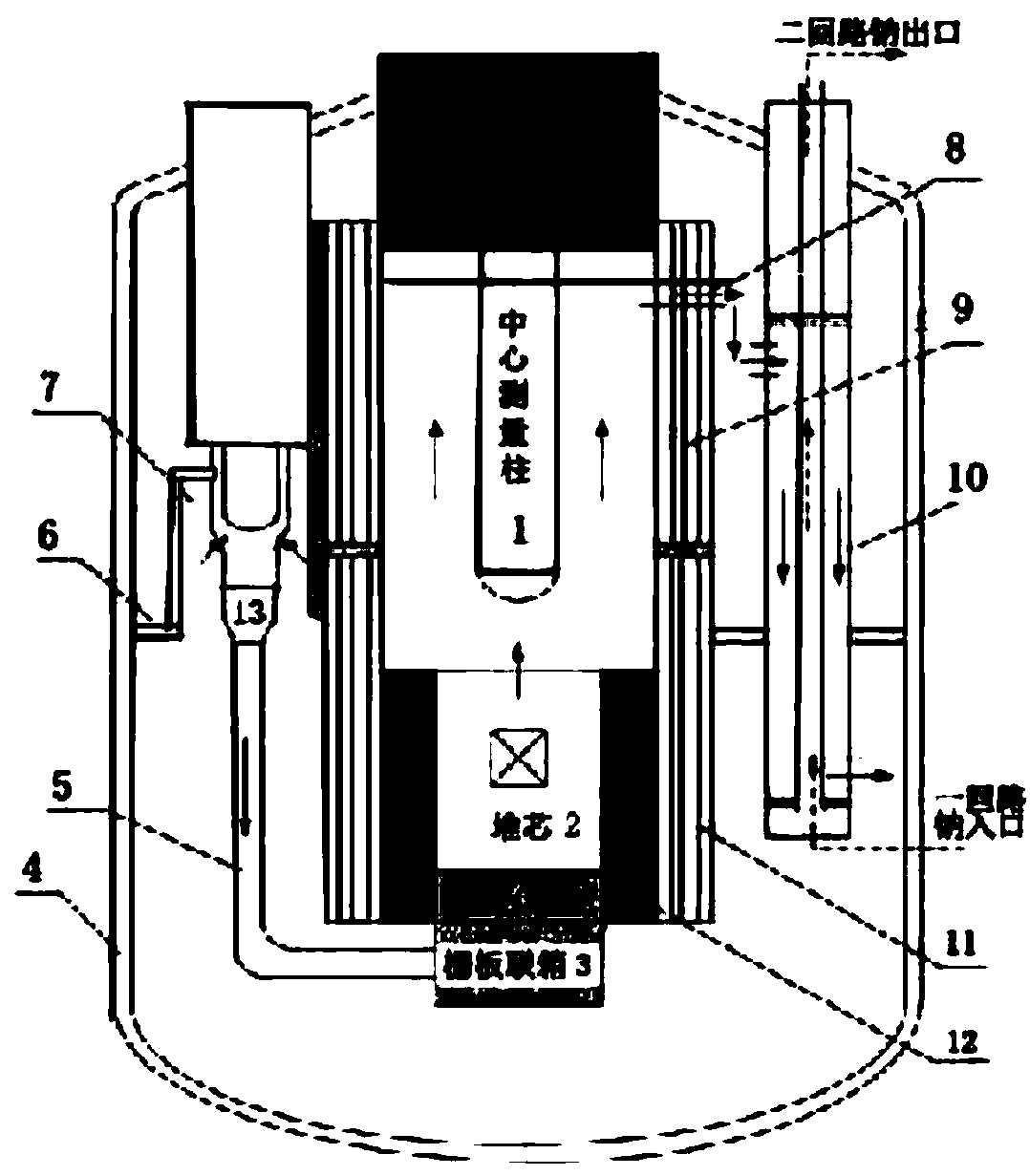

Examples

Embodiment

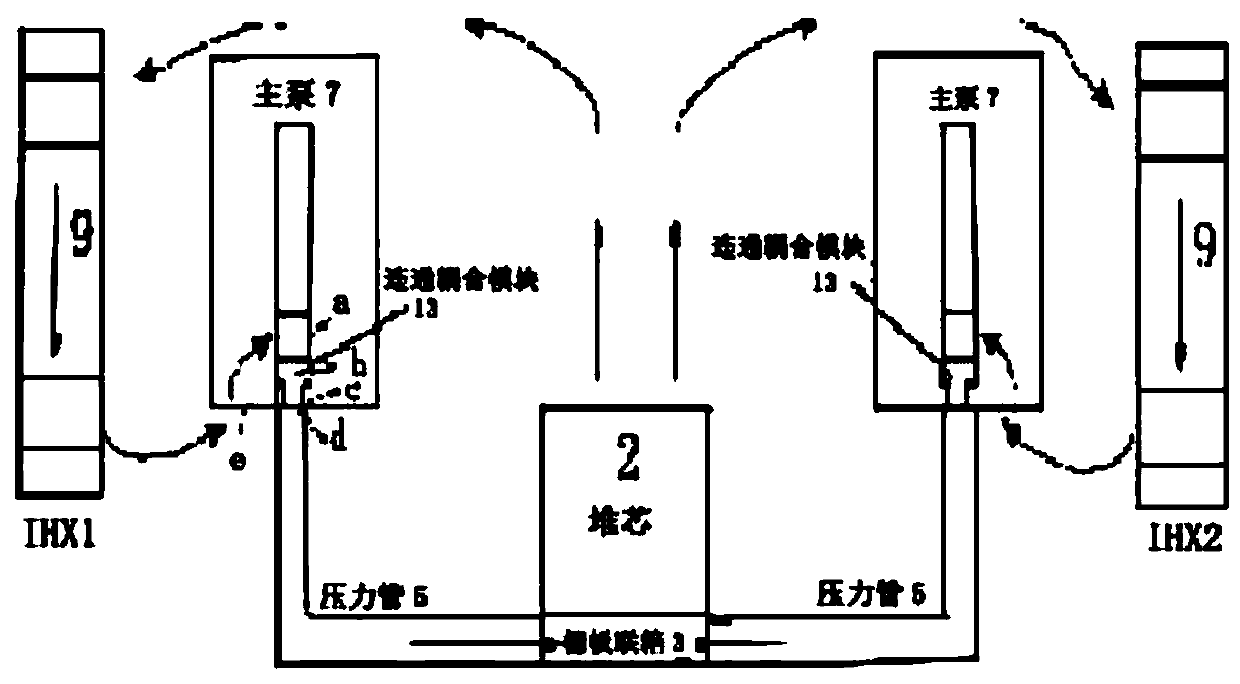

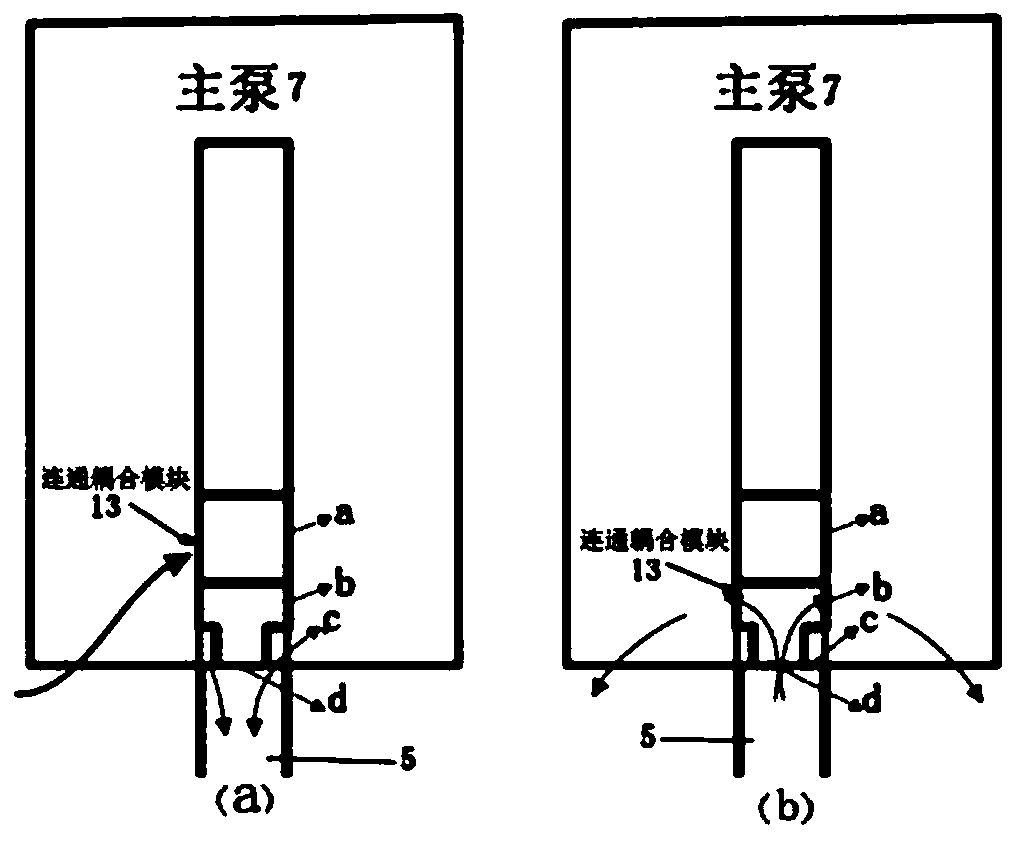

[0022] By adjusting the properties of each surface of the T-shaped connection coupling module 13 between the main pump 7 and the pressure pipe 5, it is possible to set different boundary conditions and perform calculations for different working conditions without changing the grid. Specific operation:

[0023] 1) Steady-state working condition: when performing steady-state calculations, surface c is set as the inlet boundary of constant flow and constant temperature, surface a is the pressure outlet boundary, and other surfaces connected to the coupling module are set as walls;

[0024] 2) Transient working condition 1, water loss accident on the secondary side of the steam generator: When this accident occurs, the steam generator cannot take away the heat of the intermediate heat exchanger 10 of the secondary circuit, and accordingly, the hot sodium in the primary circuit cannot be effectively The cooling power of the primary loop intermediate heat exchanger 10 drops rapidly....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com