Absorption ball reactor shutdown device for high-temperature gas-cooled reactor

A technology of high-temperature gas-cooled reactors and absorbing balls, applied in emergency protection devices, reduction of greenhouse gases, reactors, etc., can solve problems such as difficult disassembly and maintenance of ball valve heads and transmission rods, and achieve the effect of good adaptability and expanded adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

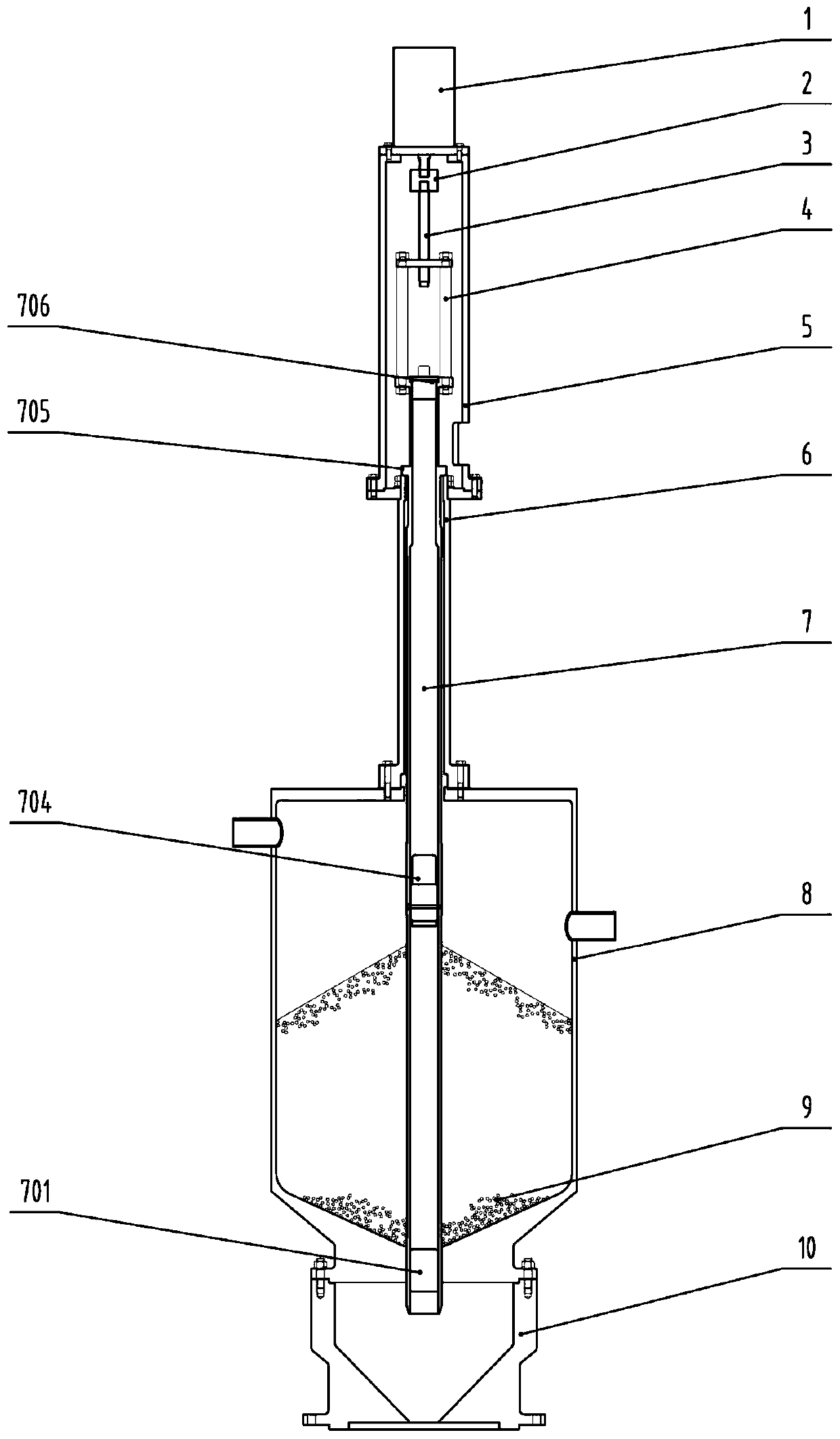

[0036] See figure 1 , according to Embodiment 1 of the present invention, a high temperature gas-cooled reactor absorber shutdown device is provided, including a ball storage tank 8 , a support pipe 6 , a driving member and a transmission rod 7 . Among them, the ball storage tank 8 bottom is provided with a ball drop port; the bottom of the support tube 6 is connected to the top opening of the ball storage tank 8; the driving member is fixed on the top of the support tube 6; the transmission rod 7 passes through the support tube 6, and the transmission rod 7 first The end is connected to the output part, and the second end of the transmission rod 7 extends into the bottom of the ball storage tank 8, and the output part drives the transmission rod 7 to lift to open and close the ball drop port, and the rising of the driving part can drive the transmission rod to move to the outside of the ball storage tank.

[0037] This kind of high-temperature gas-cooled reactor absorption ba...

Embodiment 2

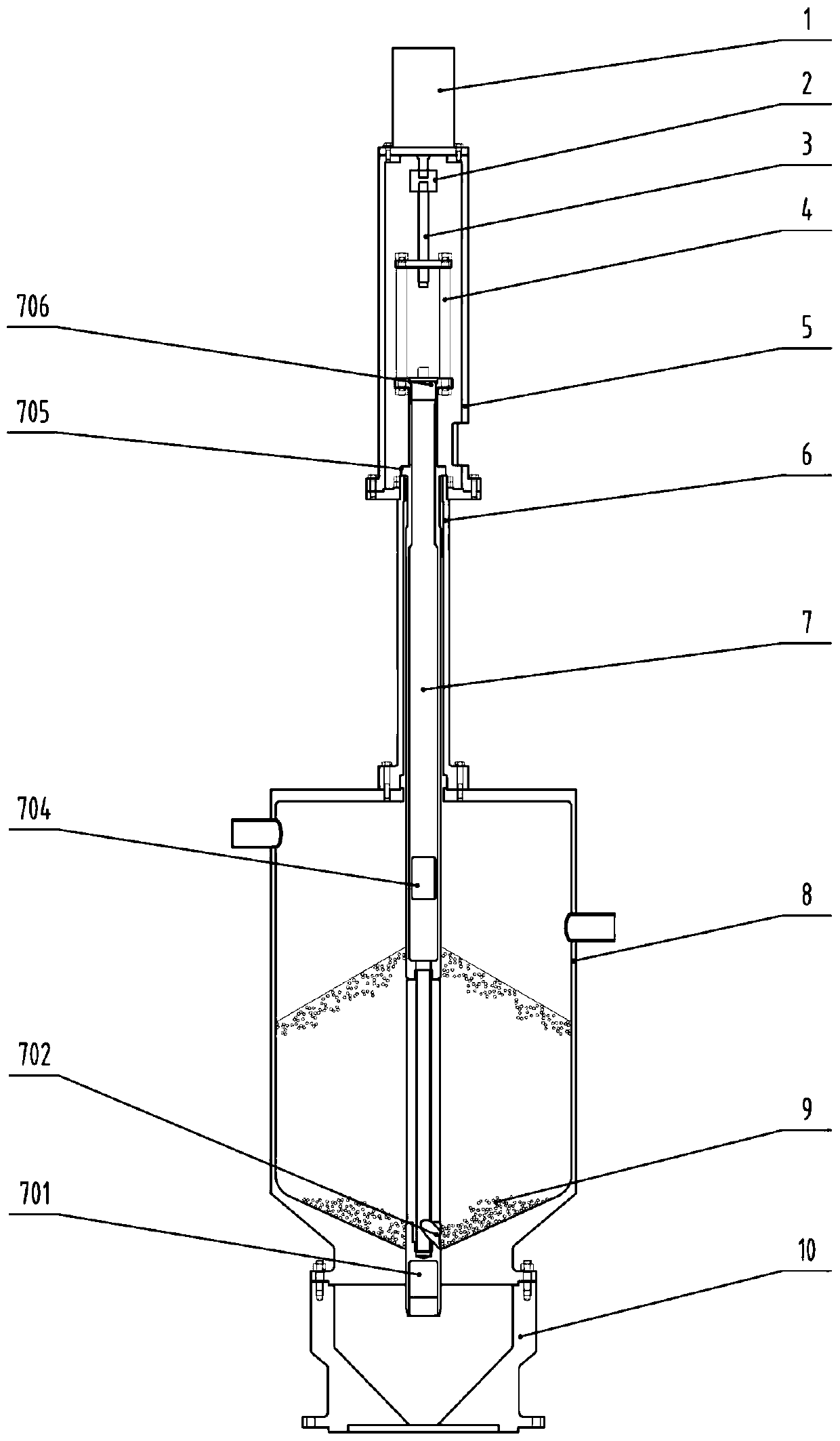

[0053] See figure 2 , the same as Embodiment 1 will not be repeated in this Embodiment 2. The difference between this Embodiment 2 and Embodiment 1 is that a suction port 702 can also be provided on the transmission rod 7, and the suction port 702 communicates with the material flow channel, and the suction port 702 is located below the injection port 704 , and a second barrier component is arranged between the suction port 702 and the discharge port 701 .

[0054] When the absorption ball 9 needs to be sucked, since the suction port 702 is connected to the material flow channel, it is only necessary to block the injection port 704, so that the absorption ball 9 inside the ball storage tank 8 can be sucked into the material flow channel , and can be sucked to the outside of the ball storage tank 8 through the material flow channel.

[0055] Wherein, the way of blocking the injection port 704 is not limited, for example, a door panel may be provided at the injection port 704,...

Embodiment 3

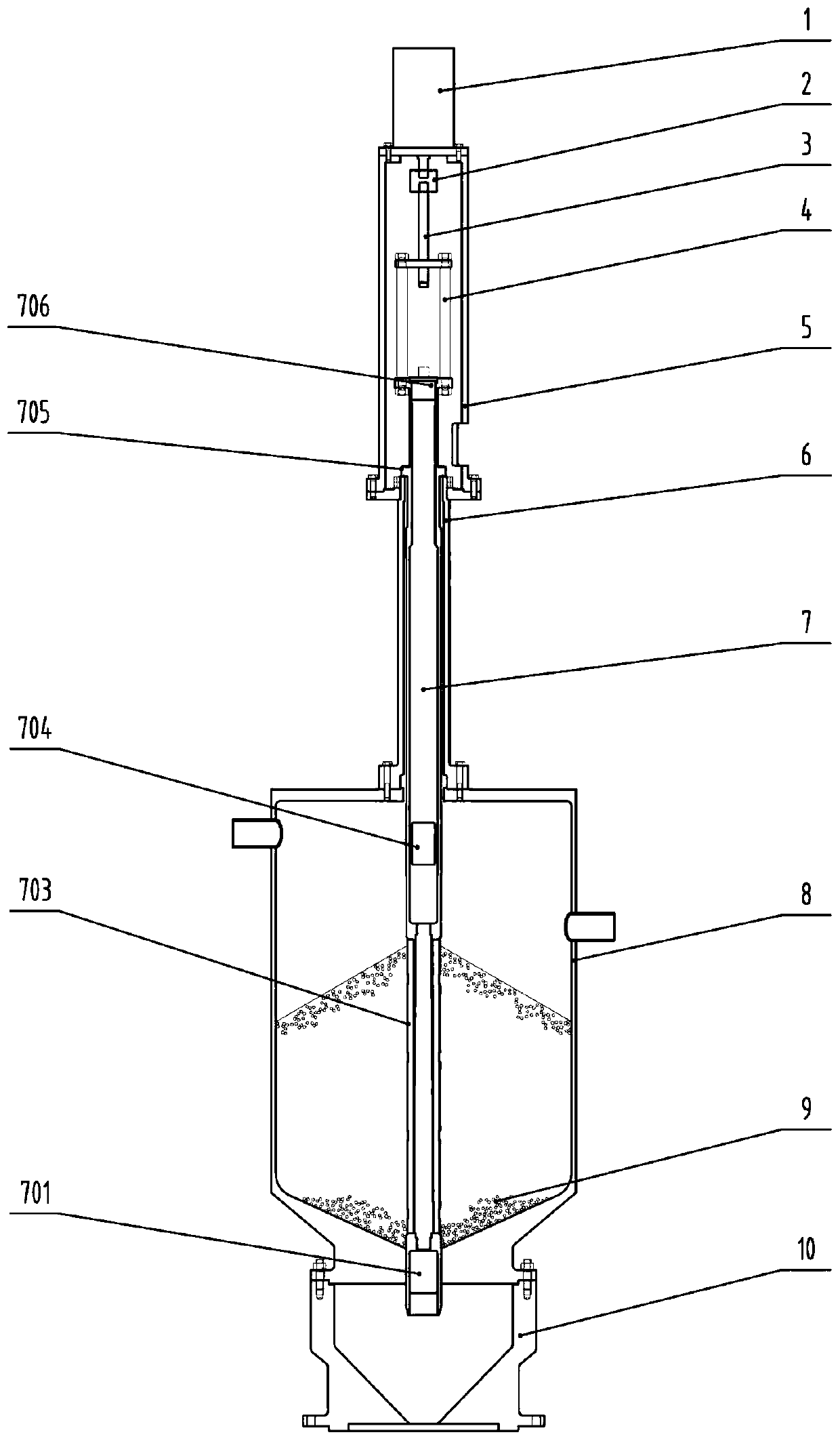

[0063] See image 3 , the same as Embodiment 1 will not be repeated in this Embodiment 3. The difference between this Embodiment 3 and Embodiment 1 is that the transmission rod 7 includes a second section 703 for setting electrodes, and the electrodes correspond to the storage tank 8 preset material level setting, and the electrode and ball storage tank 8 are connected through conductive parts.

[0064] image 3 , the second section 703 is located inside the ball storage tank 8 and corresponds to the bottom of the transmission rod 7 .

[0065] Wherein, the preset material level generally refers to the limit material level or the optimum material level that needs to be judged under a specific working condition. Taking the application of the ball storage tank 8 as an example, the preset material level refers to the highest material level, the lowest material level or the best material level corresponding to the ball falling process, or the lowest material level, the highest ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com