A kind of soybean milk processing production line

A production line, soy milk technology, applied in the peeling of vegetables or fruits, milk substitutes, food science, etc., can solve the problems of reducing beany smell, large soybean limit, easy foaming, etc., to slow down the wear speed and avoid beany smell smell, easy to clean up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

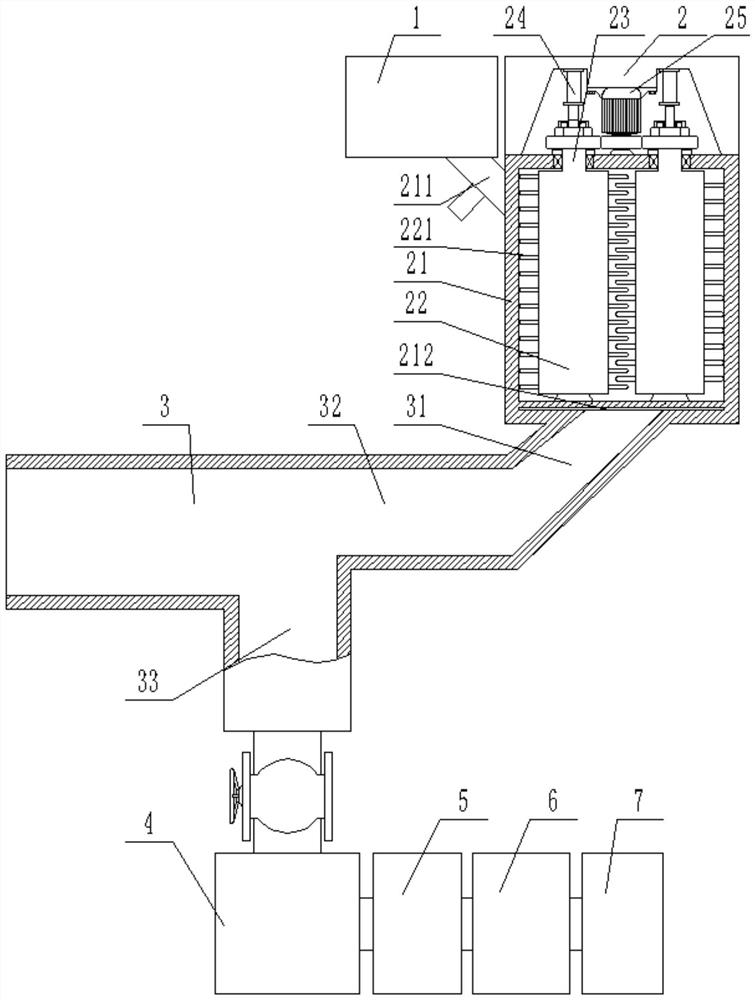

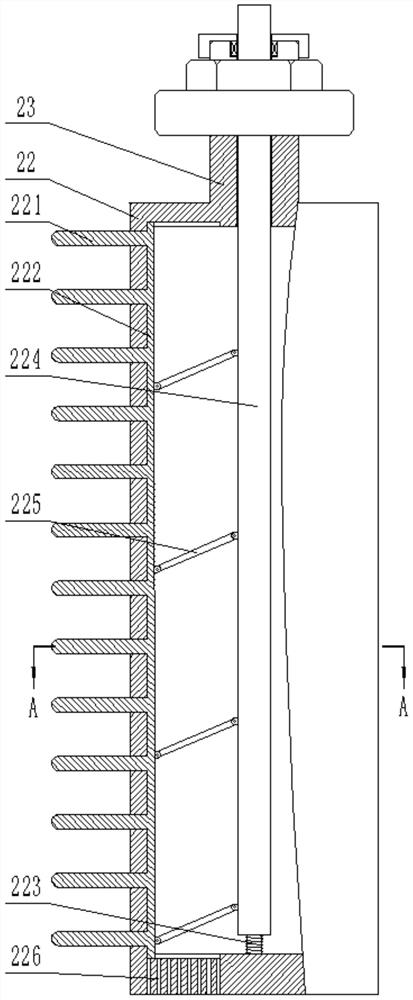

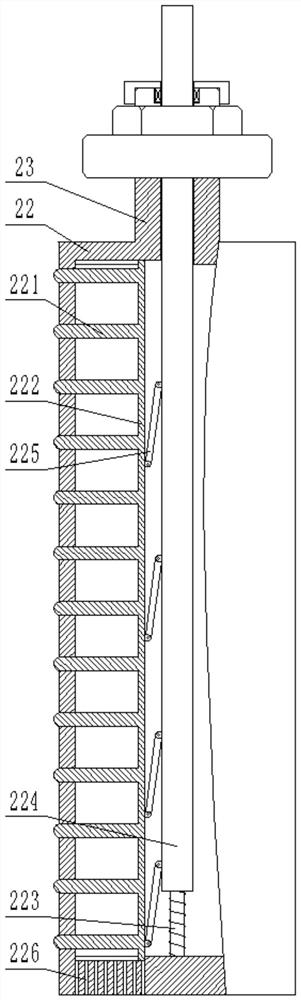

[0026] Such as Figure 1-4 As shown, the specific structure of the present invention is: a soybean milk processing production line, comprising a soaking device 1, a peeling device 2 and a separation device 3, the separation device 3 is connected with a pulping device 4, and the pulping device 4 is connected with a Modulation cylinder 5, described modulation cylinder 5 is connected with homogenizer 6, and described homogenizer 6 is connected with canned sterilizing device 7; Described peeling device 2 comprises tank body 21, and vertically forms in described tank body 21 A mixing bucket 22 is provided,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com