Anti-pollution efficient peeling and trimming device for trunk processing

A trimming device and anti-pollution technology, applied to bark, metal processing equipment, wood processing equipment, etc., can solve the problems of endangering the personal safety of workers, difficulty adapting to trunks of different thicknesses, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

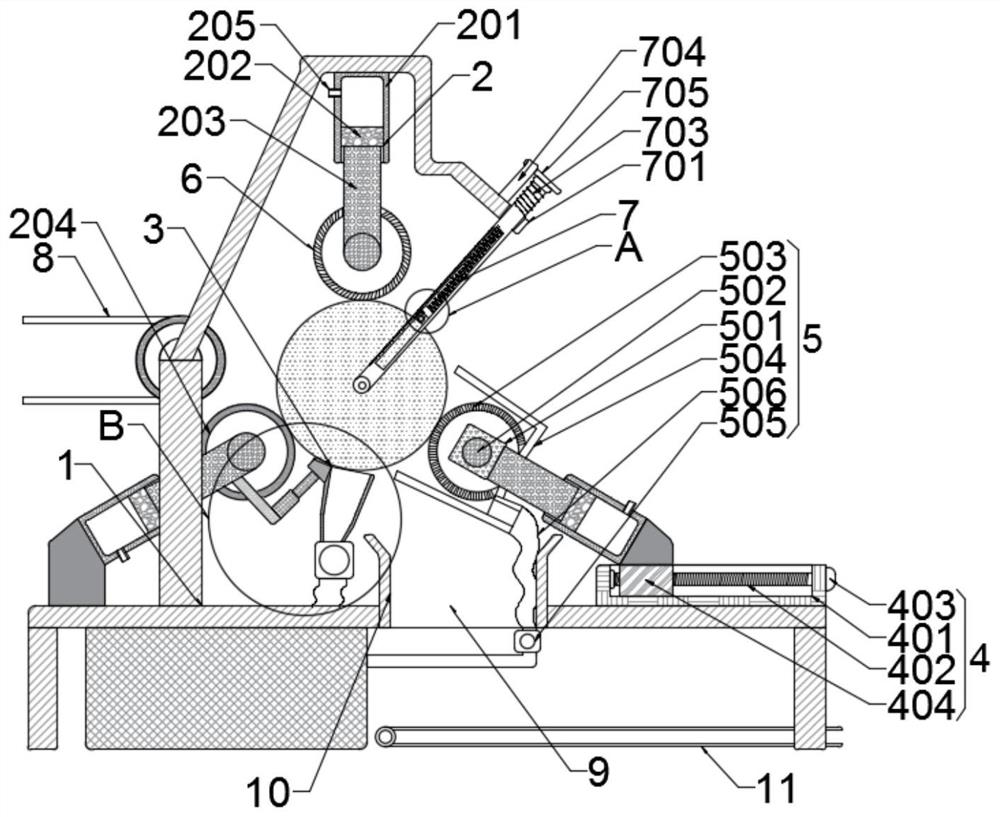

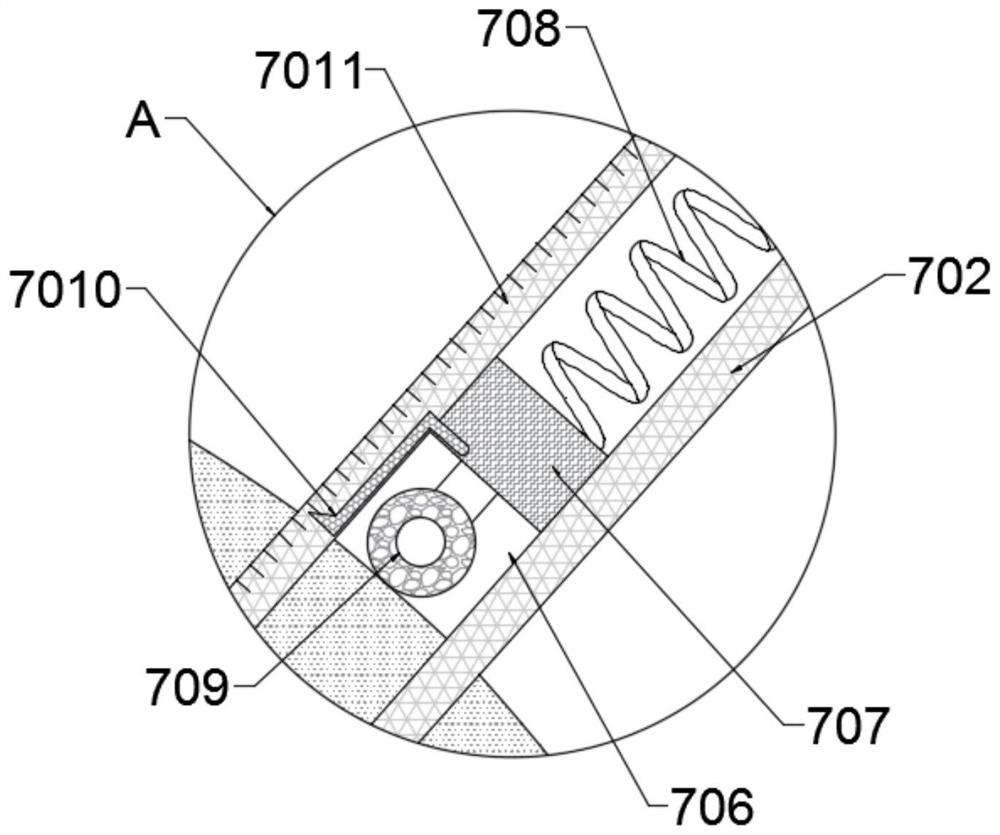

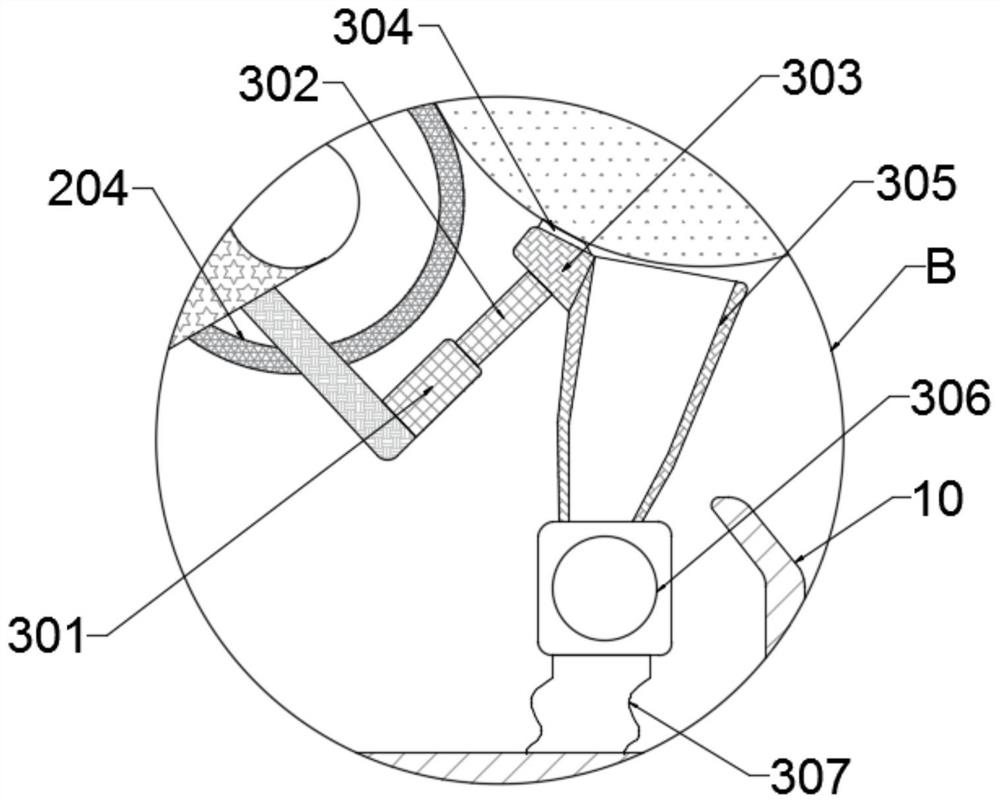

[0026] Example 1: Please refer to figure 1 and 2 , a pollution-proof high-efficiency peeling and trimming device for tree trunk processing, comprising a mounting frame 1, a peeling mechanism 3 is provided on the left side of the mounting frame 1 through a telescopic mechanism 2, a moving mechanism 4 is installed on the right side of the mounting frame 1, and the moving mechanism 4 Grinding mechanism 5 is installed on the top through telescopic mechanism 2, pressure roller 6 is arranged on the top of mounting frame 1 through telescopic mechanism 2, measuring mechanism 7 is installed on the top side of mounting frame 1, peeling mechanism 3 includes push rod motor 301, push rod motor 301 is fixed on the telescopic mechanism 2 on the left side of the installation frame 1, and the peeling plate 303 is fixed on the push rod 302 of the push rod motor 301, and the peeling knife 304 is evenly distributed on the peeling plate 303, and one side of the peeling plate 303 is connected Ther...

Embodiment 2

[0030] Example 2: Please refer to Figure 1-4, a pollution-proof high-efficiency peeling and trimming device for tree trunk processing, comprising a mounting frame 1, a peeling mechanism 3 is provided on the left side of the mounting frame 1 through a telescopic mechanism 2, a moving mechanism 4 is installed on the right side of the mounting frame 1, and the moving mechanism 4 Grinding mechanism 5 is installed on the top through telescopic mechanism 2, pressure roller 6 is arranged on the top of mounting frame 1 through telescopic mechanism 2, measuring mechanism 7 is installed on the top side of mounting frame 1, peeling mechanism 3 includes push rod motor 301, push rod motor 301 is fixed on the telescopic mechanism 2 on the left side of the installation frame 1, and the peeling plate 303 is fixed on the push rod 302 of the push rod motor 301, and the peeling knife 304 is evenly distributed on the peeling plate 303, and one side of the peeling plate 303 is connected There is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com