Peeling device for elongated bamboo shoot

A slender bamboo shoot technology, applied in the peeling of vegetables or fruits, food science, application, etc., can solve the problems of bamboo shoot meat quality difference, inability to peel, bamboo shoot meat crushing, etc., to achieve simple structure and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

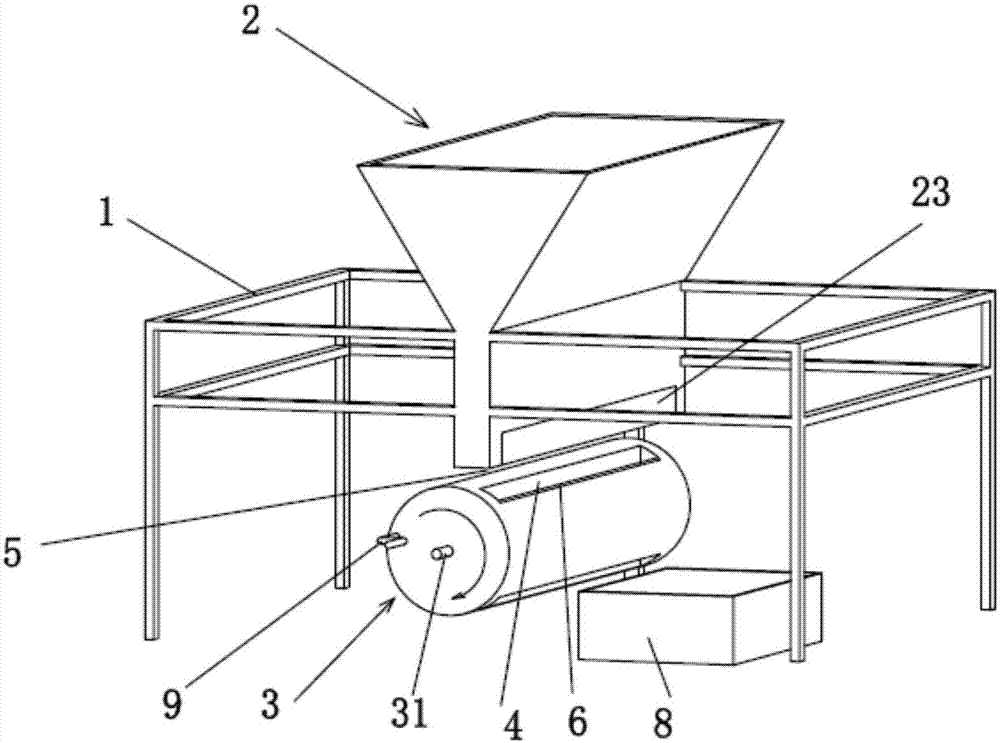

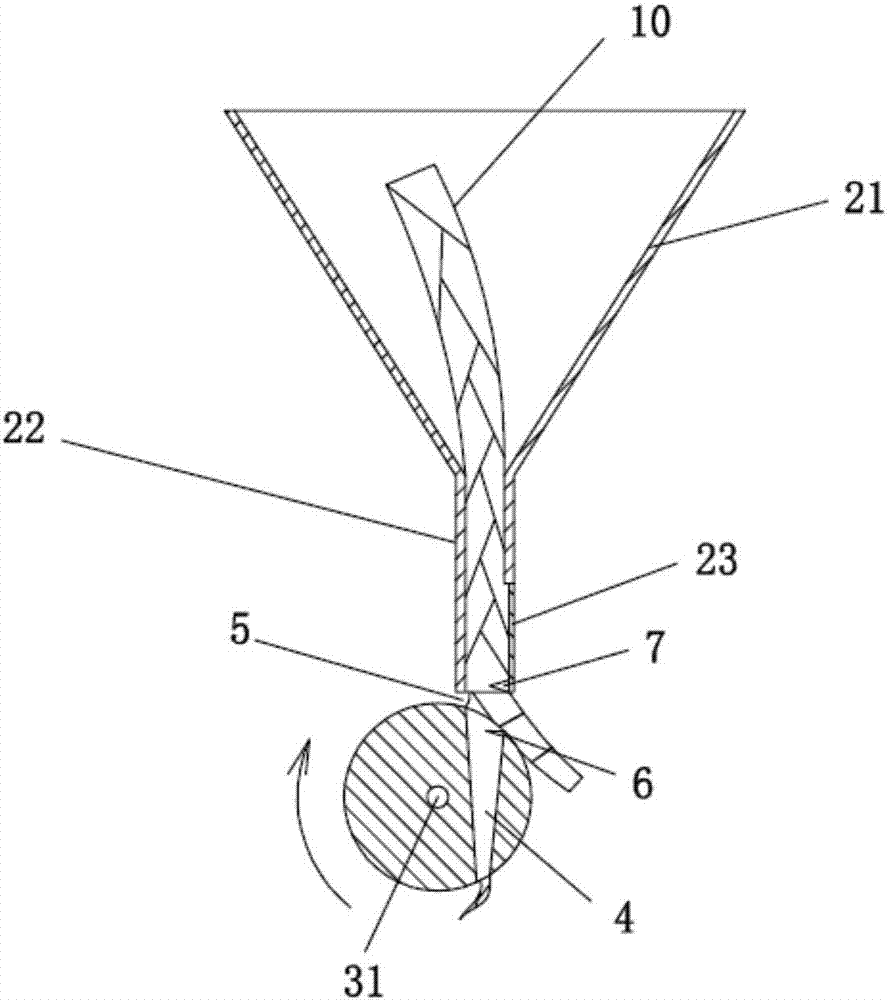

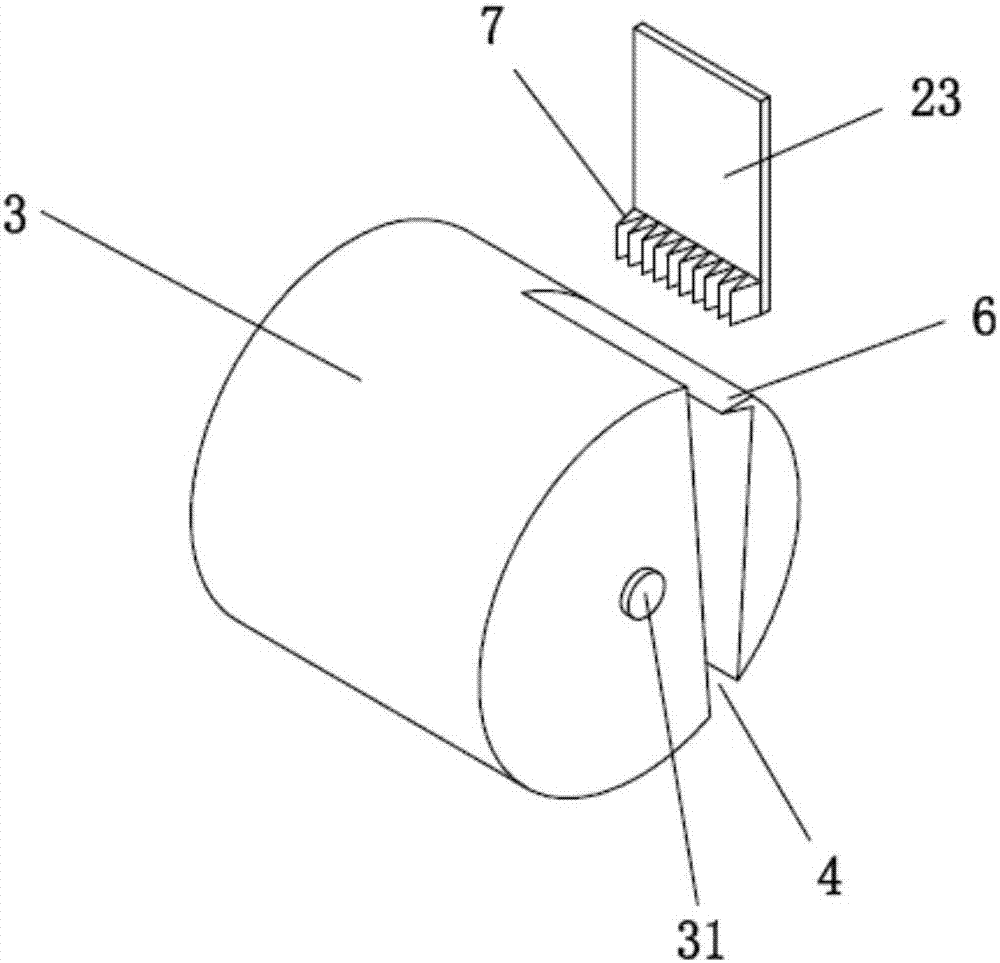

[0023] Such as Figure 1~3 As shown, the elongated bamboo shoot peeling device includes a frame 1 on which a feeding bin 2 and a peeling assembly 3 are arranged. The feeding bin 2 includes an open portion 21 and a flat portion 22 connected up and down. The distance between the flat portions 22 in the width direction is 3-8 cm.

[0024] The peeling assembly 3 is a rotating body with a rotating shaft 31 , and the rotating body is manually driven by a crank handle 9 . The peeling assembly 3 is located below the feeding bin 2, and the peeling assembly 3 is provided with a channel 4 for accommodating the heads of the bamboo shoots 10. The channel 4 communicates with the feeding bin 2, and the channel 4 is a through hole with a trapezoidal cross section, and the top of the channel 4 is wider than the bottom of the channel 4. A gap 5 for allowing bamboo shoots 10 to pass is provided between the bottom of the feeding bin 2 and the passage 4, and the bamboo shoots 10 fall into the r...

Embodiment 2

[0027] Such as Figure 4~5 As shown, the difference between Embodiment 2 and Embodiment 1 lies in that: the rotating body of the peeling assembly 3 is driven by a motor 32 , and a switch 33 for controlling the motor 32 is arranged on the frame 1 . In addition, the section of the channel 4 is arc-shaped, and the channel 4 is a through hole with a constant diameter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com