An oxidation hanger for automatic production

An oxidizer and guide post technology, applied in anodizing, coating, electrolytic components, etc., can solve the problems of low production efficiency, high labor cost, troublesome operation, etc., and achieve the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

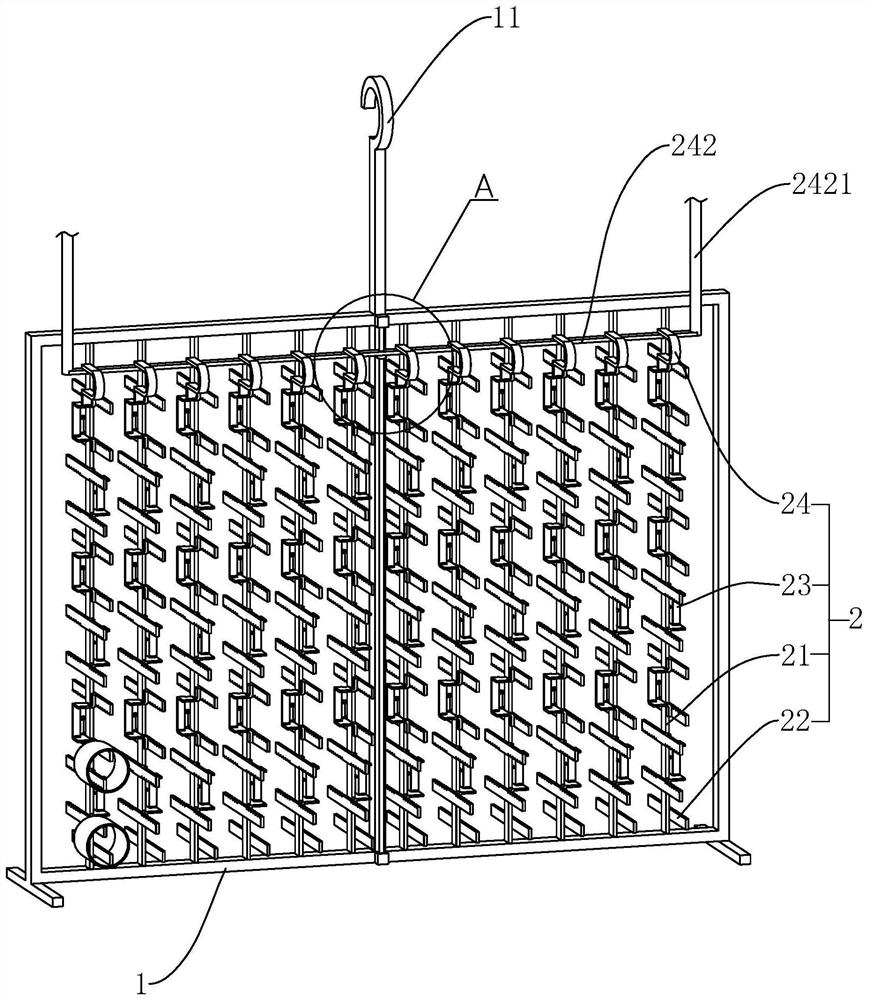

[0041] Embodiment 1, this embodiment discloses an oxidation hanger for automatic production, such as figure 1 As shown, it includes a mounting frame 1, a hook 11 arranged on the mounting frame 1, a fixing mechanism 2 for fixing workpieces to be oxidized; A positioning device 22 at the lower end of the guide post 21, a number of fixing parts 23 that are slidably connected to the guide post 21, and a limiting device 24 arranged on the fixing part 23 at the uppermost end of the guide post 21; The position of the bottom fixing part 23; the limit device 24 is used to drive the topmost fixing part 23 on the guide post 21 to move along the guide post 21; The fixing arms 231 of two adjacent fixing members 23 can realize the fixing of the workpiece to be oxidized by changing the distance between them.

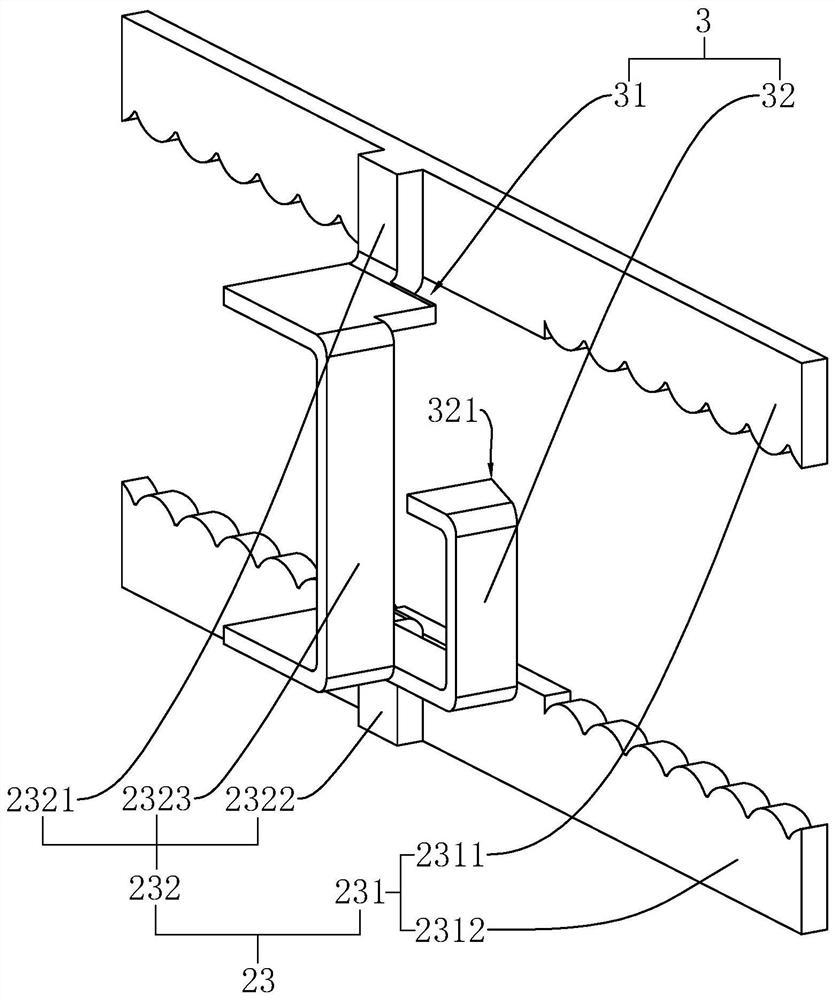

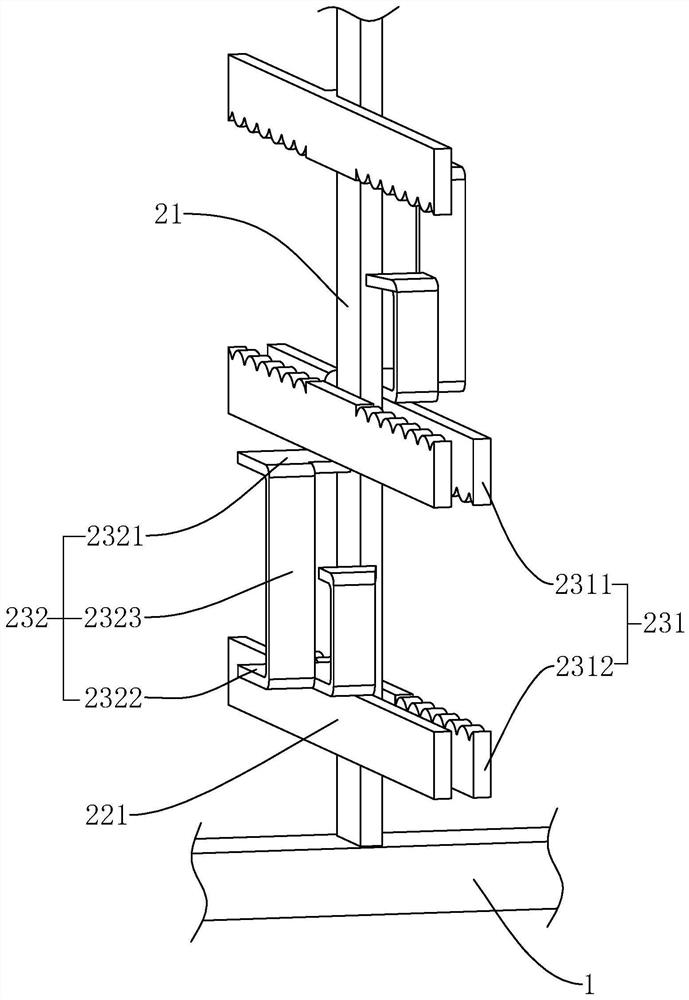

[0042] like figure 1 , figure 2 As shown, the fixed arm 231 includes an upper arm 2311 and a lower arm 2312 arranged at intervals along the length direction of the guide post 21. Th...

Embodiment 2

[0054] Embodiment 2, the difference between this embodiment and Embodiment 1 is that, if Figure 8 As shown, the guide structure 3 includes two upper guide pieces 33 that are relatively arranged on the upper arm 2311 toward the middle guide post 21, and two lower guide pieces 34 that are relatively arranged on the lower arm 2312; Formed along the L-shaped or U-shaped groove and turned outwards, the lower guide piece 34 is formed by grooved along the L-shaped or U-shaped on the lower arm 2312 and turned outwards, so that between the upper guide piece 33 and the upper arm 2311, Between the lower guide piece 34 and the lower arm 2312 are respectively formed guide passages 31 corresponding to the cross-sectional shape of the guide post 21 . The upper guide piece 33 and the lower guide piece 34 are respectively formed by bending and slotting on the upper arm 2311 and the lower arm 2312 , which has a simple structure, saves materials, and is easy to process. The upper guide piece 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com