Static test device for engineering pile detection

A technology of static load test and engineering pile, which is applied in the direction of foundation structure engineering, foundation structure test, construction, etc. It can solve problems such as damage, collision between counterweight and pallet, and no buffer structure, so as to reduce loss and damage, Effect of reducing loss and damage and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The mechanisms involved in the present invention or the technical terms used are further described below. In the following detailed description, reference texts accompanying the legends are a part hereof, and are presented by way of illustration of certain embodiments in which the invention may be practiced. We do not exclude that the present invention can implement other specific solutions and change the mechanism of the present invention without departing from the scope of use of the present invention.

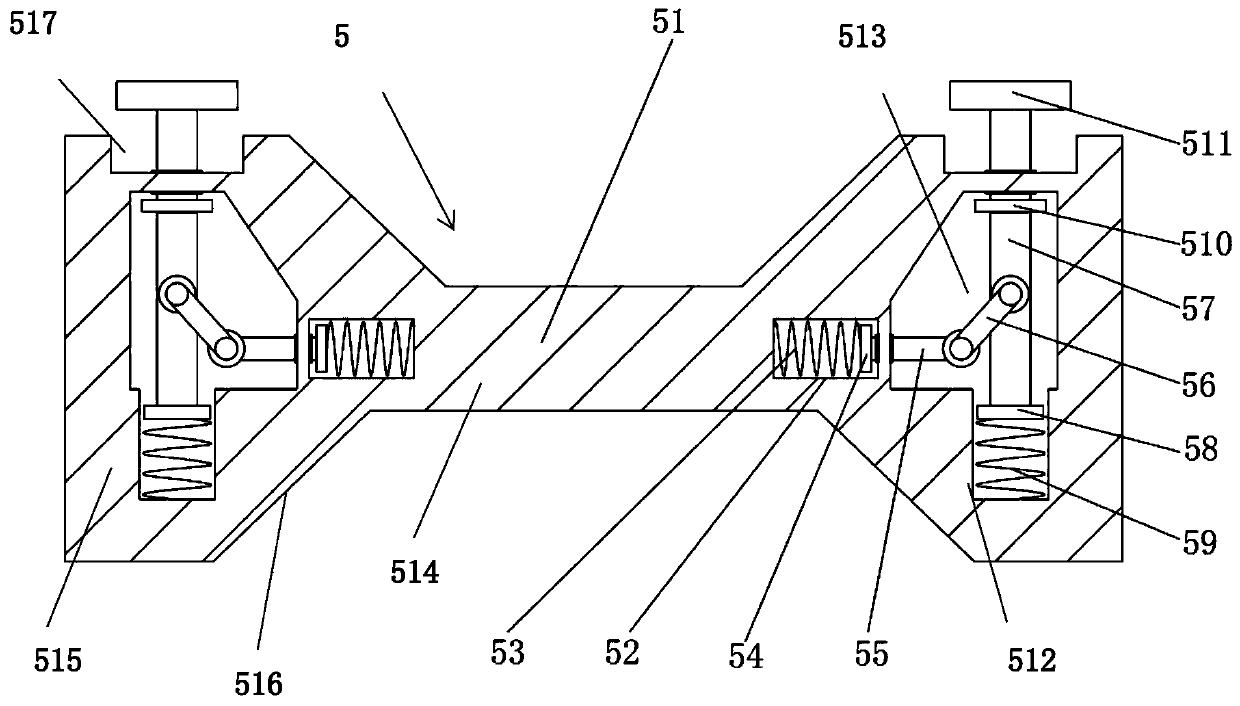

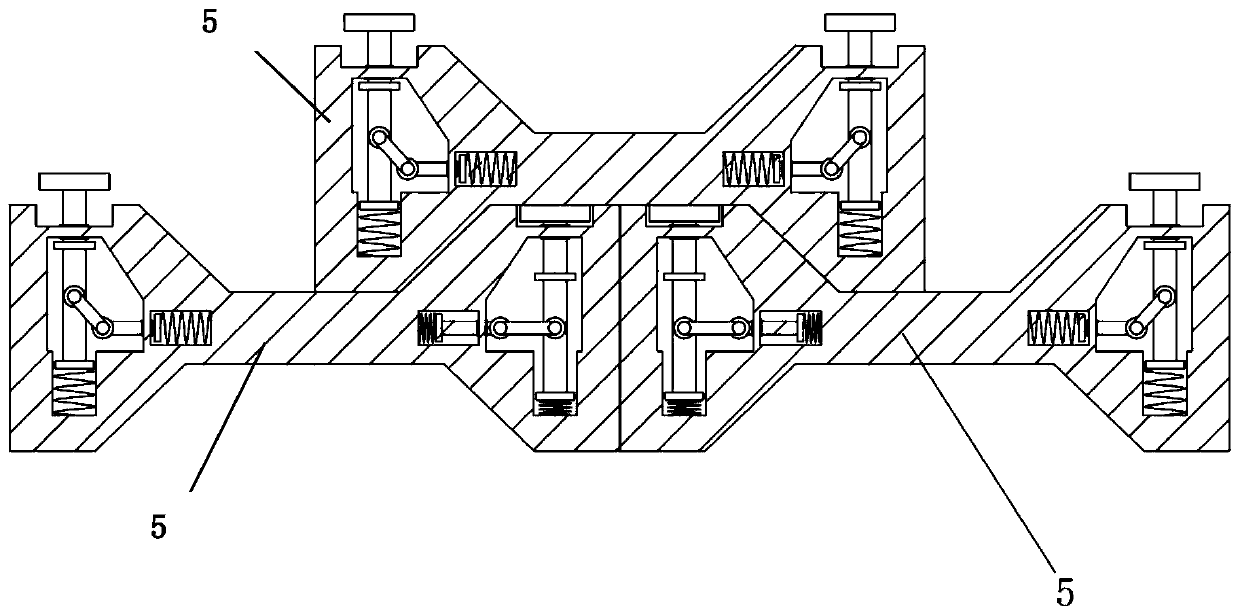

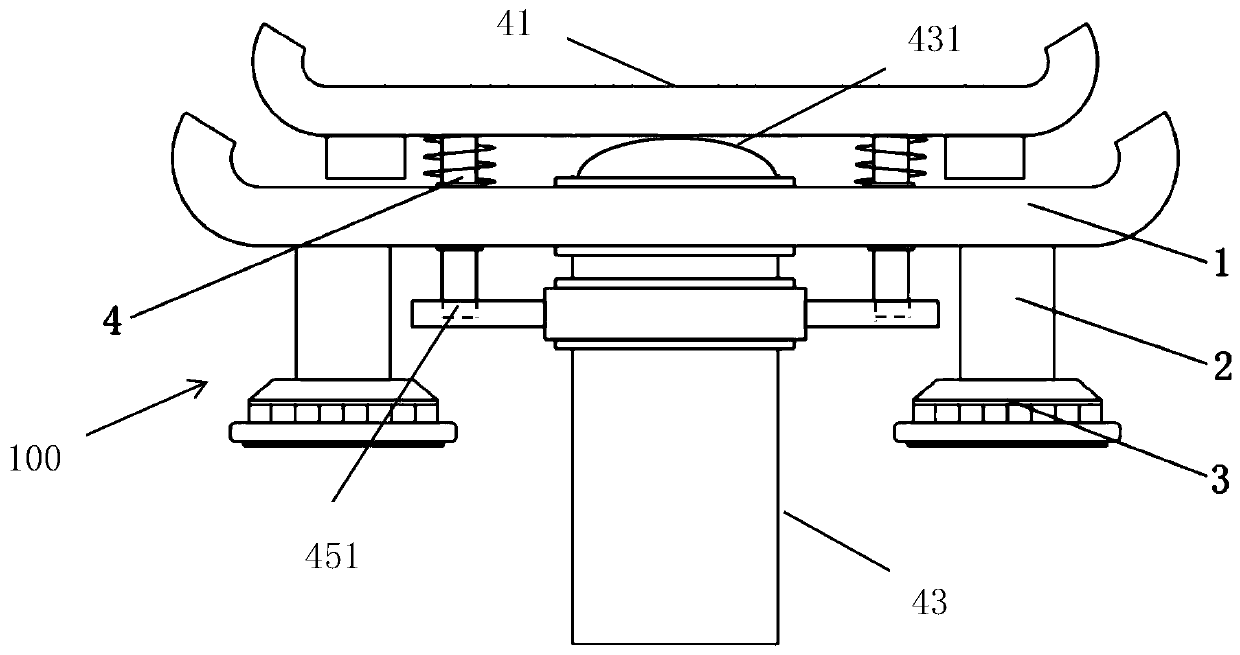

[0053] Such as figure 1 As shown, the counterweight 5 of the present invention includes a configuration main body 51 and a buffer structure located on the counterweight main body. In some embodiments, the counterweight body 51 has a structure with a concave center and two convex ends, which facilitates stacking and stacking of the counterweights 5 . Specifically, such as figure 1 As shown in , the counterweight body 51 includes a beam 514 , and bumps 515 are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com