Inner hole oil stain removing device

A technology of oil stains and inner holes, which is applied in cleaning methods and utensils, chemical instruments and methods, and cleaning methods using gas flow, etc., can solve the problems of small parts that are difficult to handle and low efficiency, and achieve high-efficiency work and high efficiency. Efficiency inner hole degreasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

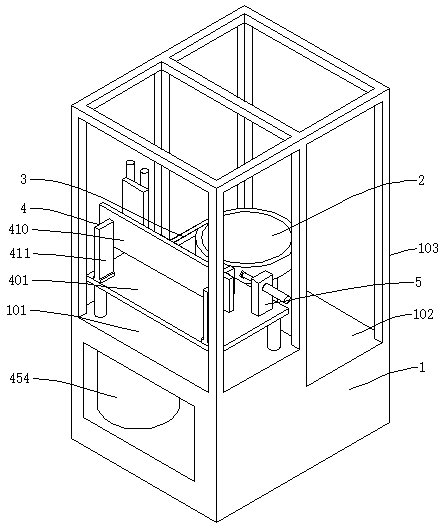

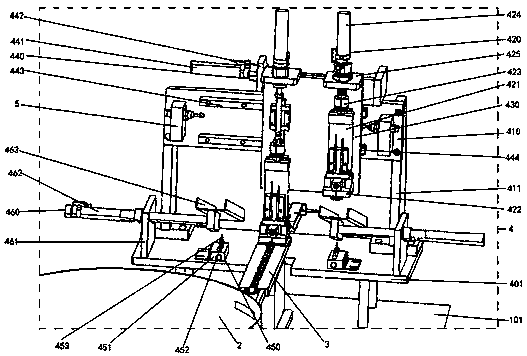

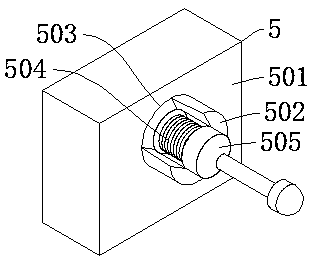

[0024] Such as figure 1 and figure 2 As shown, a device for removing oil stains in inner holes includes a chassis 1, a high-level work surface 101 and a low-level work surface 102 are arranged inside the chassis 1, a frame frame 103 is installed above the chassis 1, and the low-level work surface 103 is installed above the chassis 1. A vibrating screening disc 2 is installed on the working table 102, and a power degreasing device 4 is installed above the high-order working table 101. At the feeding place, the direct vibrating track 3 has grooves for parts transfer, so that the parts can be transferred smoothly; the power degreasing device 4 includes a base 401, two jaw mechanisms 420, a double-station carrier plate 430, and a double-station push Mechanism 440, two degreasing mechanisms 450, two unloading mechanisms 460 and a base fixing plate 410. 430 is slidably installed on the front side of the base fixing plate 410, the double-station pushing mechanism 440 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com