Inverted-H-shaped beam assembly equipment and inverted-H-shaped beam manufacturing method

A manufacturing method and I-beam technology, applied in the direction of metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of affecting production efficiency, relying heavily on personnel quality, and consuming man-hours, so as to reduce the degree of dependence on people and control the overall Assembling accuracy and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Typical embodiments that embody the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

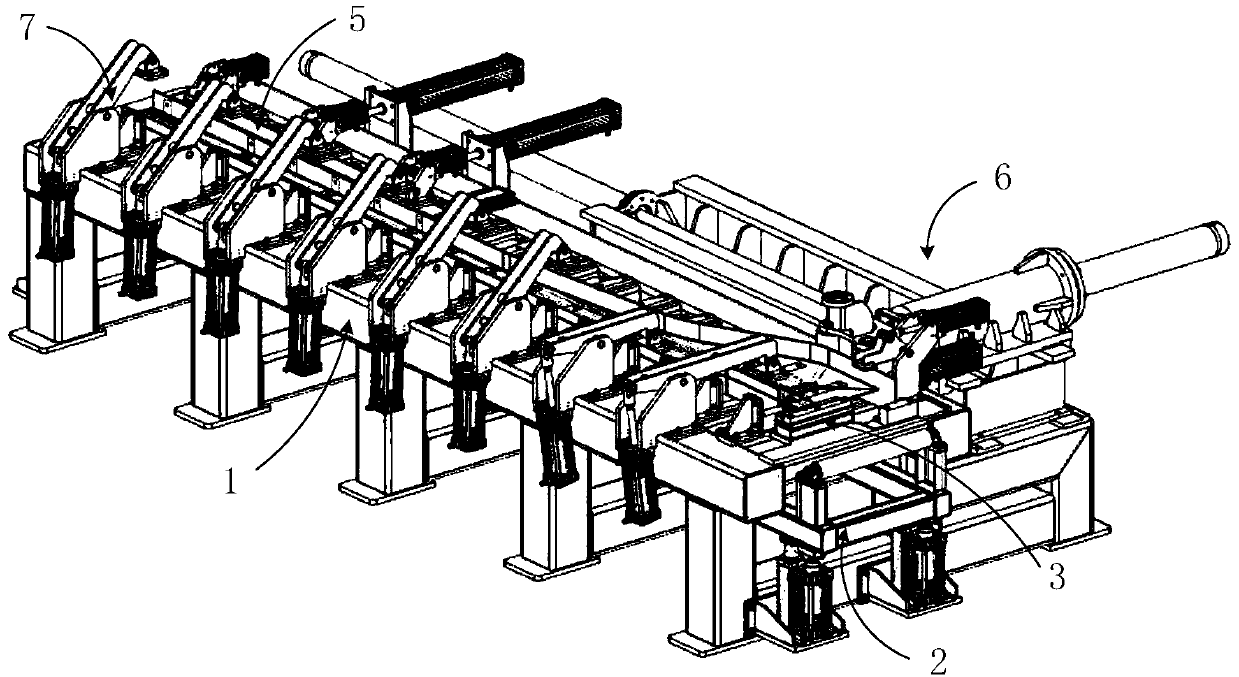

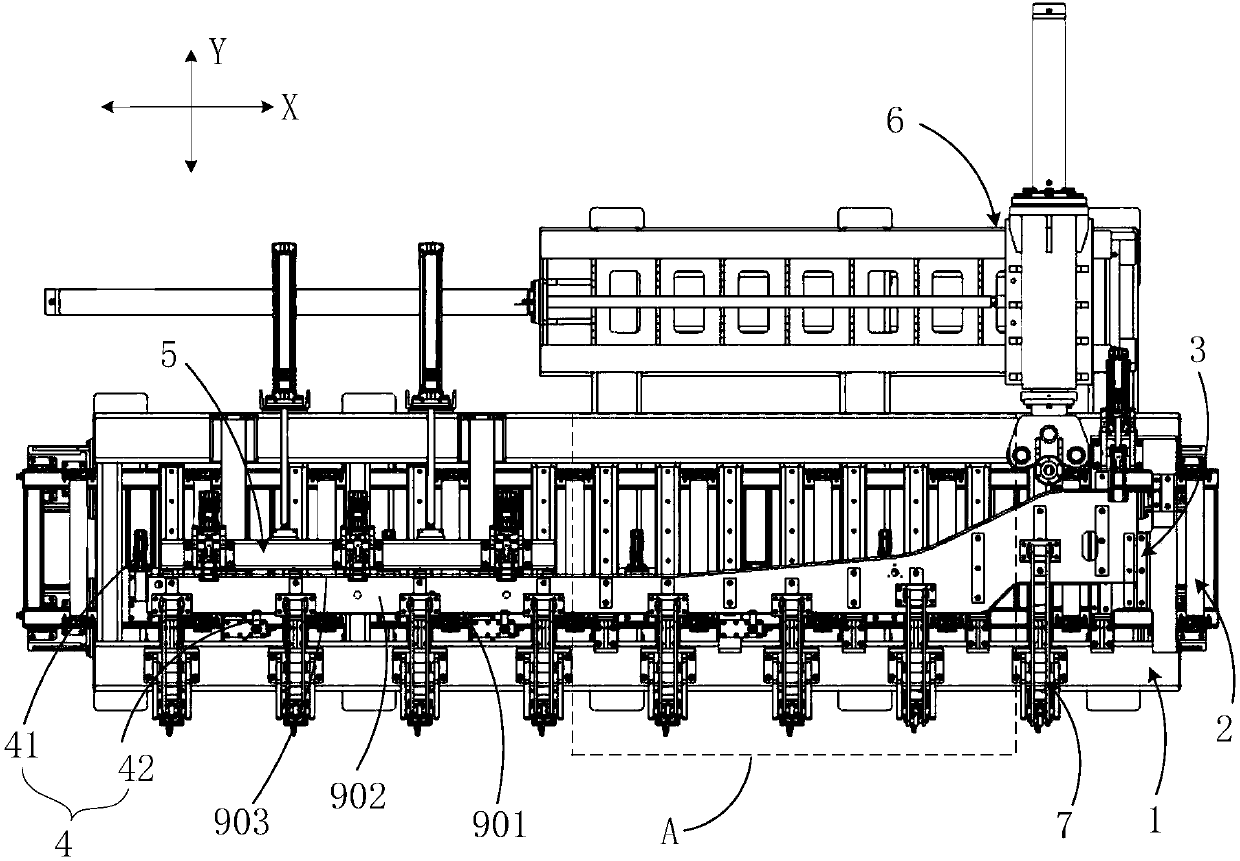

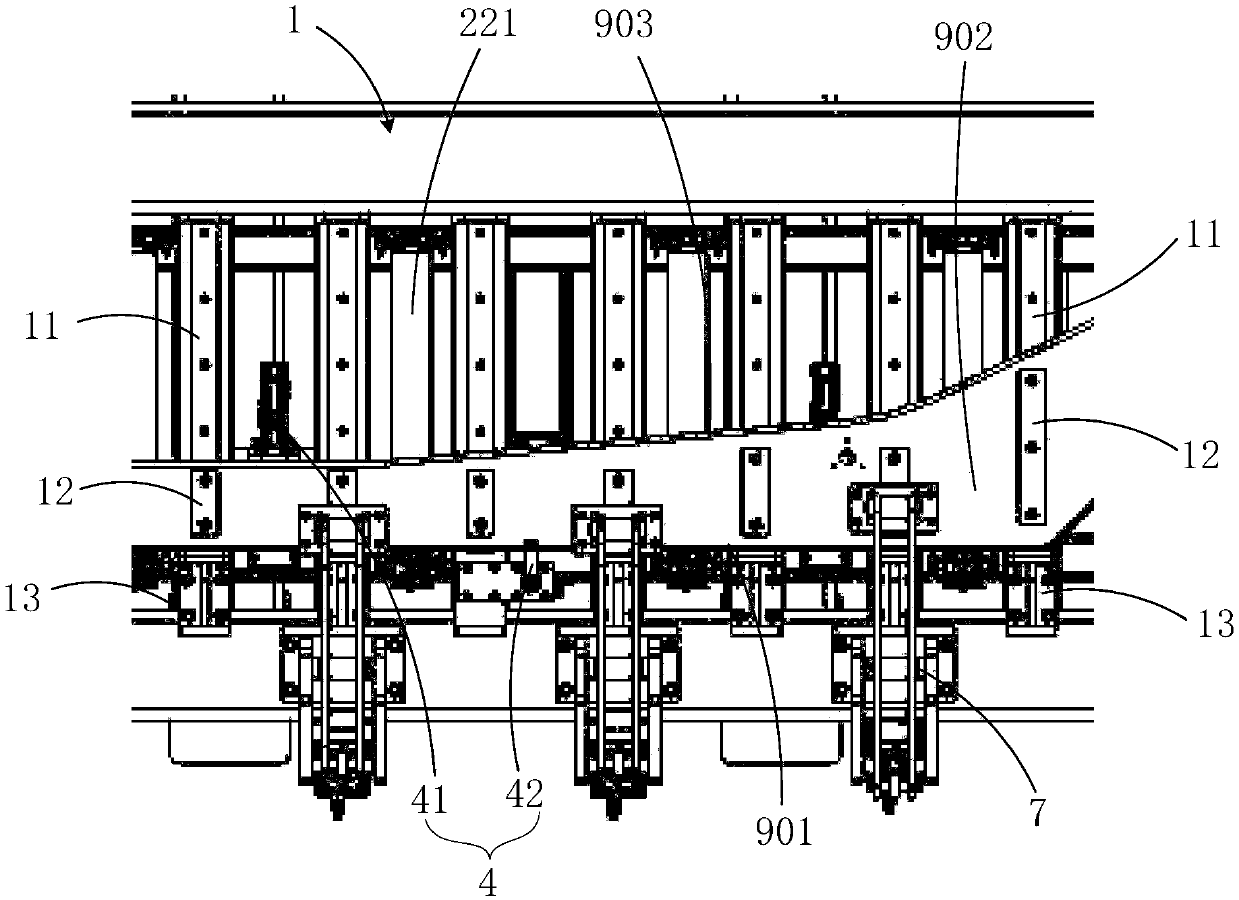

[0060] The invention relates to an I-beam assembling device (hereinafter referred to as the assembling device), which is used for assembling an upper flange, a web, and a lower flange in a steel plate state into a variable-section I-beam. The variable-section I-beam has a fixed section and a variable section, and is especially suitable as a longitudinal beam for the frame of semi-trailers such as straight-back frame vehicles, small gooseneck frame vehicles, straight-back flat rail bins, and gooseneck flat rail bins. .

[0061] refer to figure 1 and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com