Elevator lift car and damping device

A vibration damping device and elevator car technology, which is applied in the field of elevators, can solve problems such as not being able to meet the use requirements of the elevator system, achieve the effects of convenient control, reduce low-frequency vibration, and meet the use requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

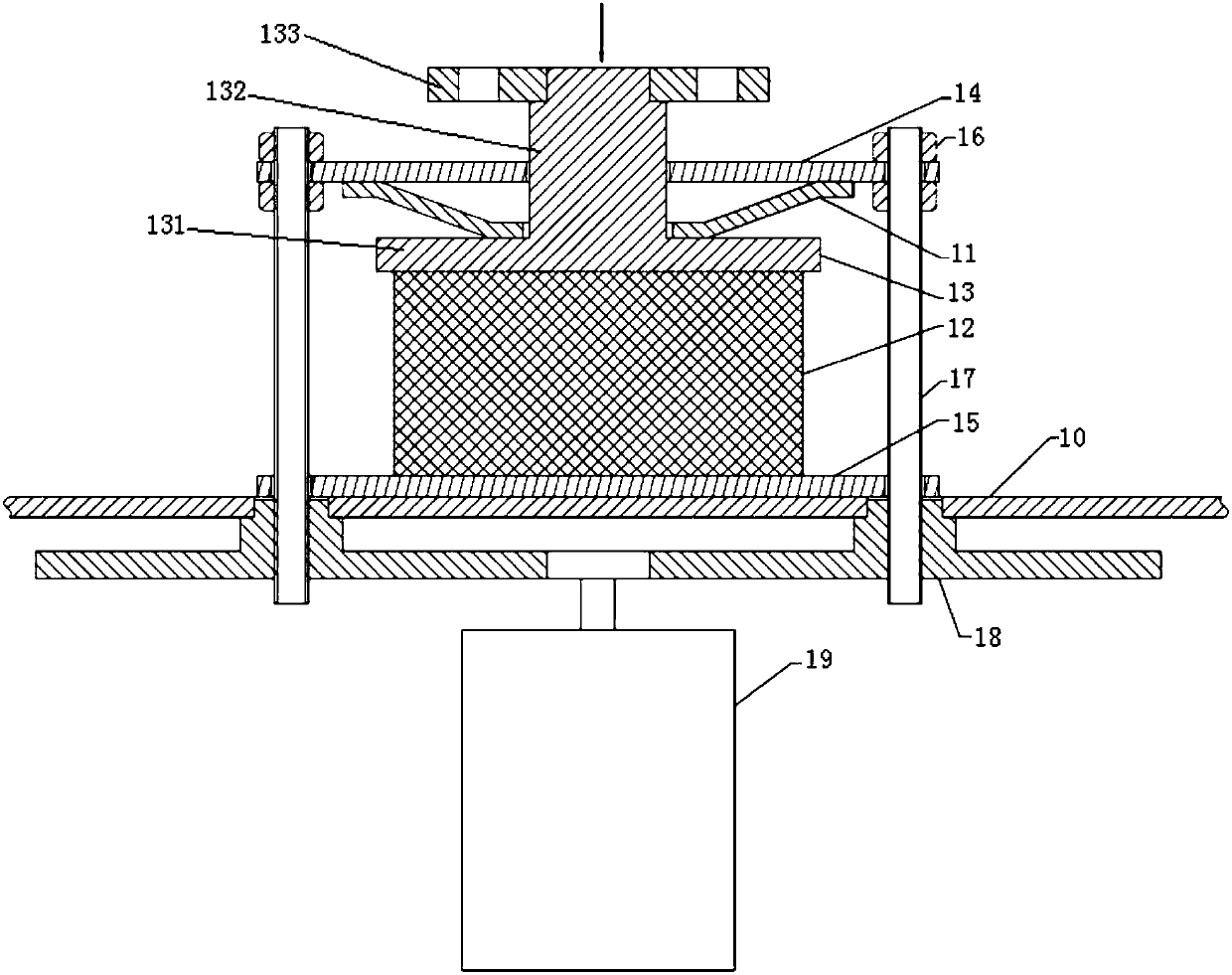

[0103] Elevator car, including damping device, adjusting device, measuring device and controller;

[0104] The damping device is installed on the top of the car or the bottom of the car;

[0105] The measuring device is used to detect the load of the vibration reduction device;

[0106] The damping device includes a positive stiffness element and a negative stiffness element;

[0107] The controller is configured to output an adjustment control signal to the adjustment device according to the load of the vibration reduction device;

[0108] The adjustment device is used to adjust the mechanical characteristics of the vibration reduction device according to the adjustment control signal.

[0109] The elevator car of the first embodiment is based on the concept of a quasi-zero stiffness vibration isolator. The controller controls the adjustment device in real time to adjust the overall mechanical characteristics of the vibration reduction device according to the actual load of the vibratio...

Embodiment 2

[0111] Based on the elevator car of the first embodiment, the positive stiffness element is connected in parallel with the negative stiffness element.

[0112] Preferably, the negative stiffness element is realized by an unstable structure, and when the load exceeds a limit value, the ratio of the load increment to the deformation increment is negative.

[0113] Preferably, the negative stiffness element is designed as a combination of one or more butterfly springs, diaphragm springs or buckling beams according to the force requirements.

[0114] Preferably, the negative stiffness element is an electromagnetic device.

[0115] The electromagnetic device is an electromagnet or a combination of an electromagnet and a permanent magnet.

[0116] Preferably, the positive stiffness element is made of conventional damping materials such as coil springs, rubber or polyurethane, and the ratio of the load increment to the deformation increment is positive.

[0117] Preferably, the adjustment devic...

Embodiment 3

[0122] The elevator car based on the first embodiment, such as Figure 4 As shown, the vibration damping device 1 is arranged between the car bottom 22 and the lower beam or supporting frame 23.

[0123] In the elevator car of the third embodiment, the mechanical characteristic curve of the vibration damping device can be adjusted in real time through the controller, so that the vibration damping device works in a small rigidity area, and the vibration isolation ability of the car bottom 22 is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com