Converter smelting control method based on slag composition prediction

A control method and converter smelting technology, which is applied in the manufacture of converters, etc., can solve problems such as no solution, delayed calculation result prediction delay, and missing initial data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

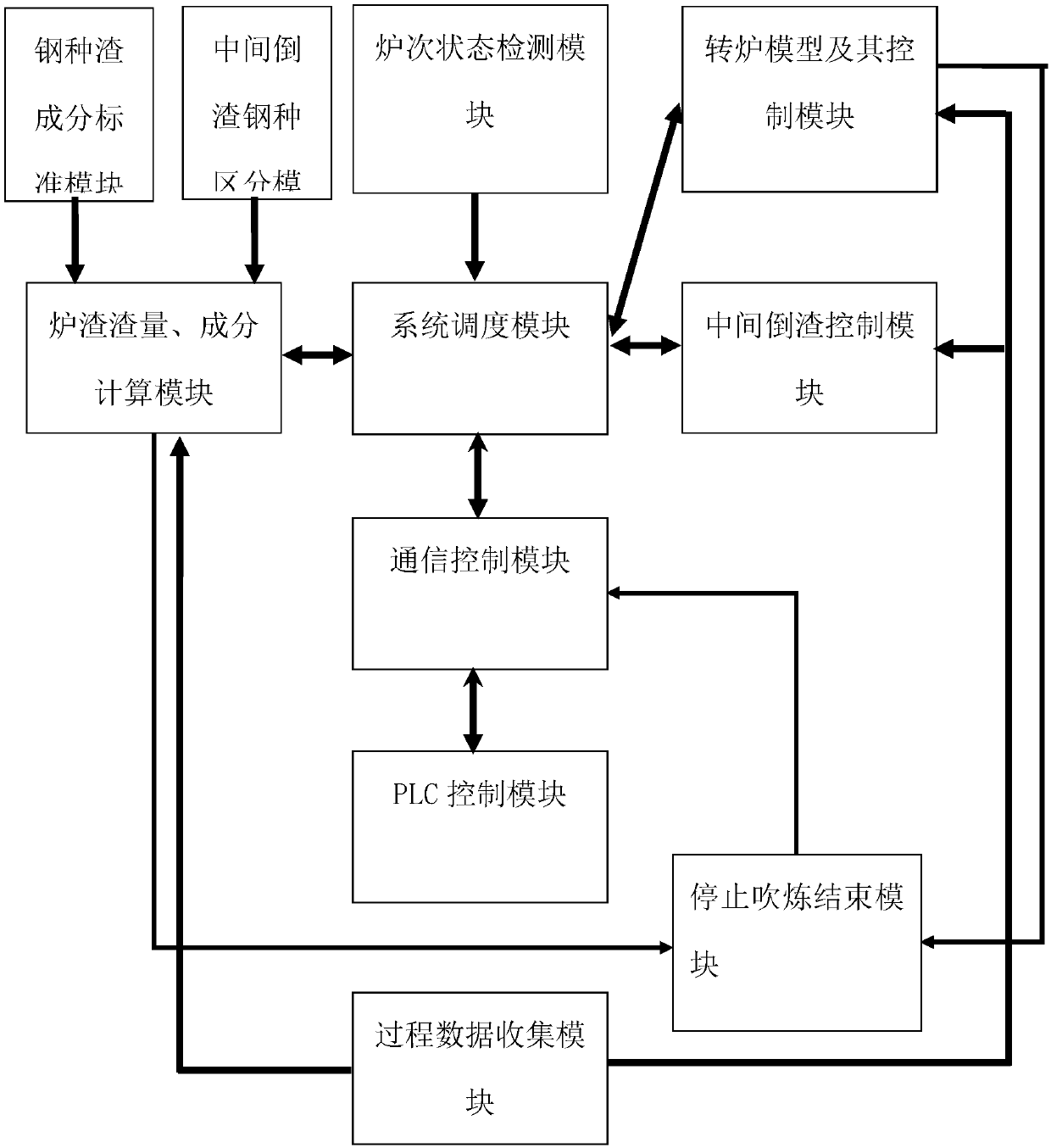

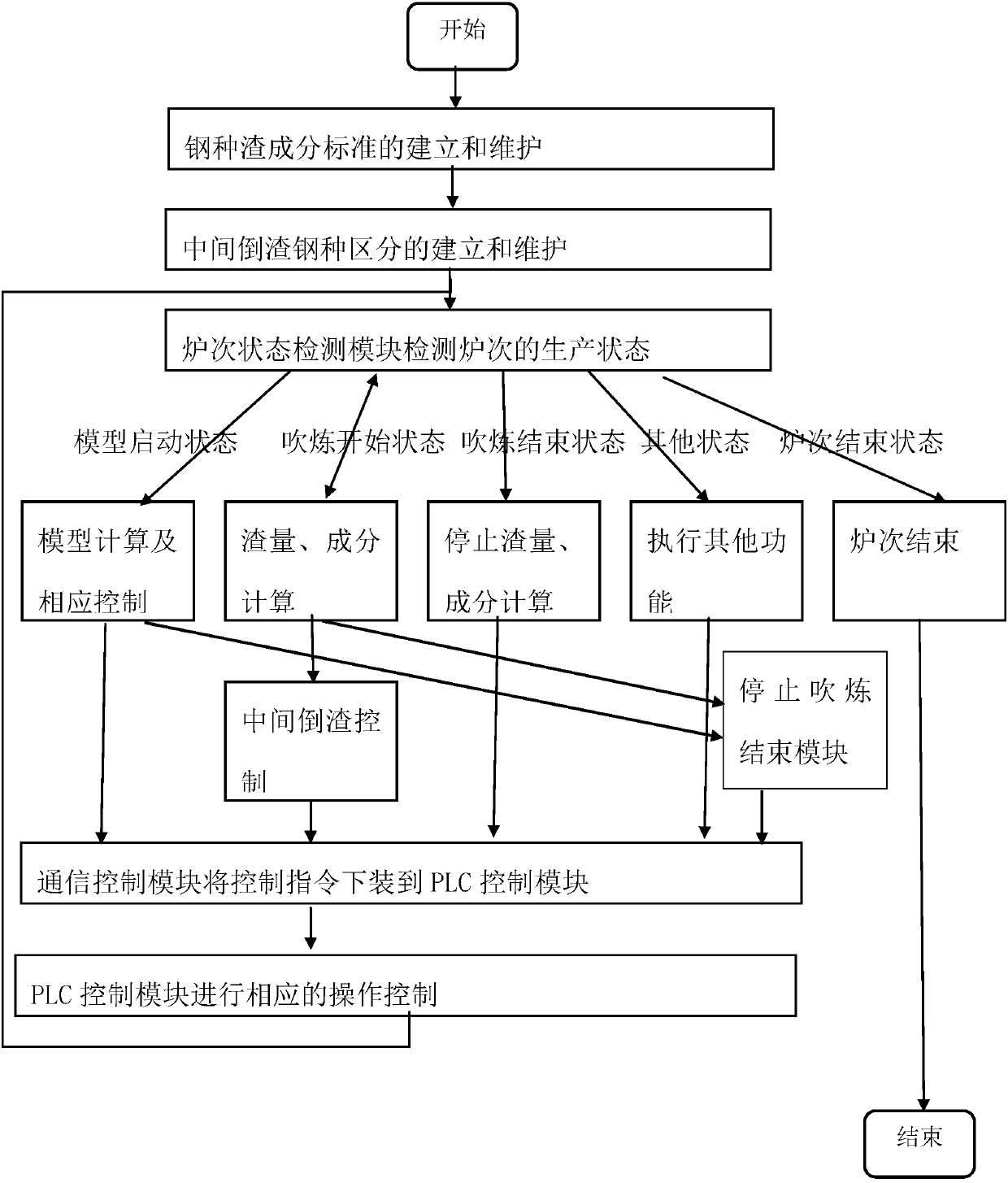

[0125] see figure 1 , figure 2 , a converter smelting control device based on slag composition prediction, including the following control modules: steel grade slag composition standard module: used to store slag composition standards corresponding to different steel grades; intermediate slag dumping steel grade distinction module: used to store different steel grades Whether it is necessary to carry out intermediate slag dumping in the smelting process; furnace state detection module: used to detect the furnace state of converter production; system scheduling module: used to call unused function modules according to the furnace state; process data collection module: use Used to collect production data in the production process; slag amount and composition calculation module: used to calculate the slag amount and composition of slag in real time; intermediate slag dumping control module: used to control the operation control of intermediate slag dumping; stop blowing end modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com