An aluminum alloy composite refiner, strengthening agent and its preparation method and device

A technology of aluminum alloy and strengthening agent, applied in the field of metal materials, can solve the problems of poor wettability, environmental pollution, difficult preparation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

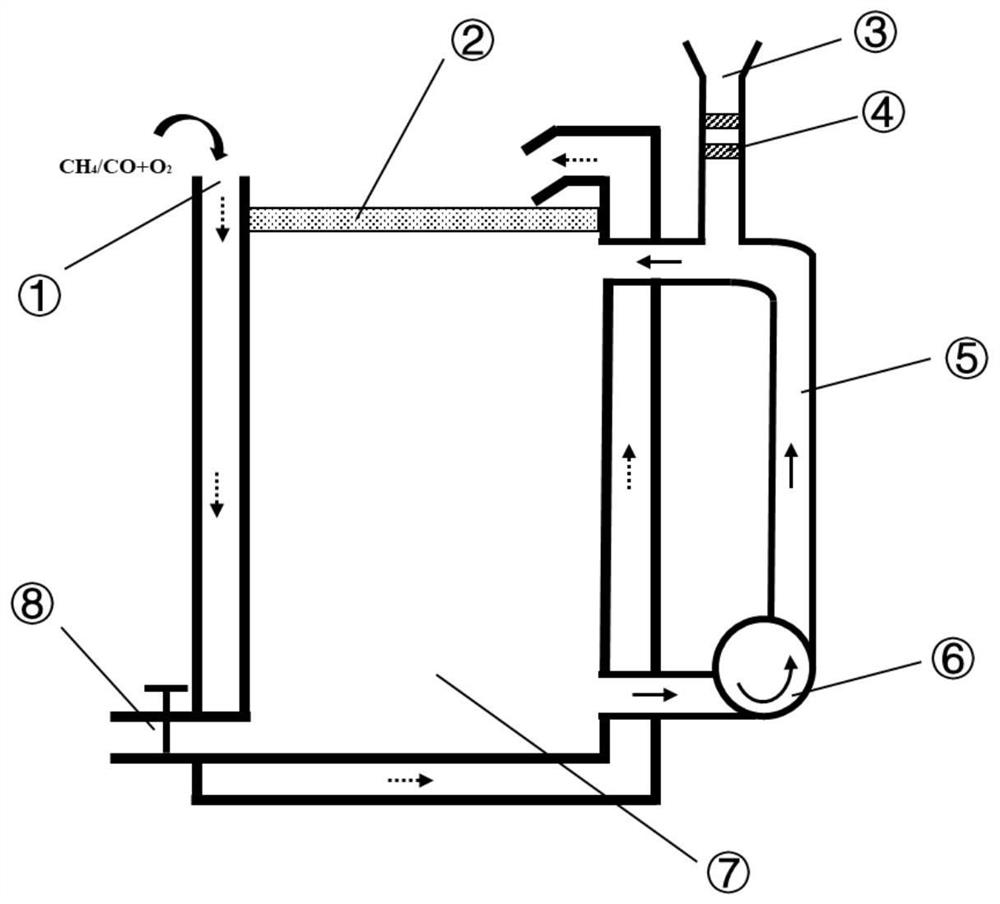

Method used

Image

Examples

Embodiment Construction

[0027] Specific implementation example 1

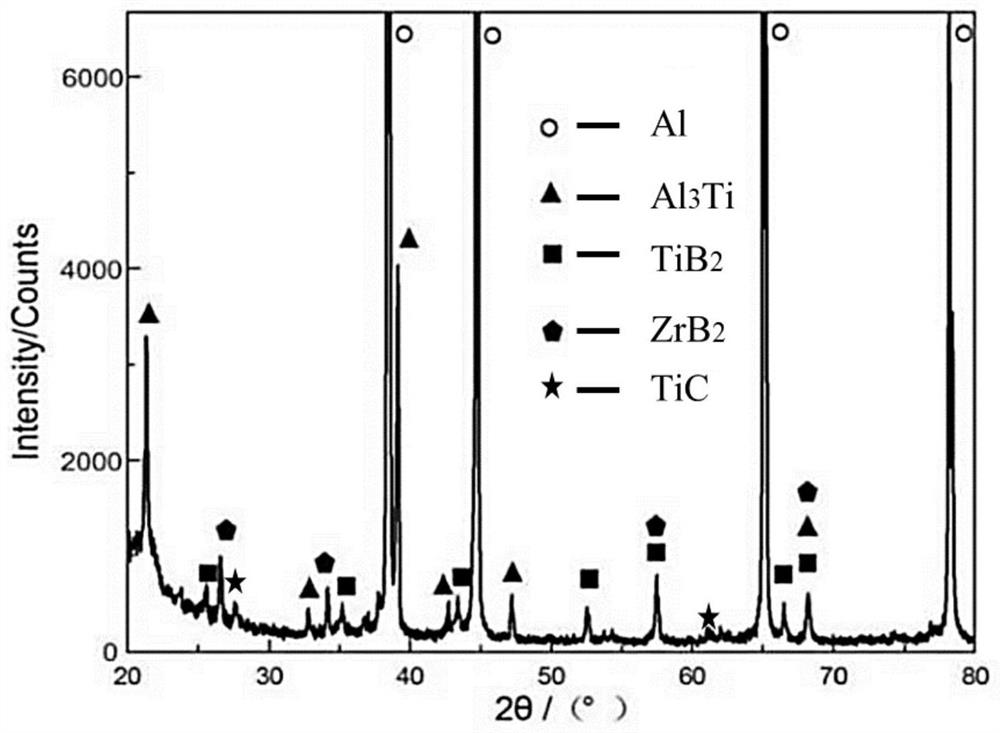

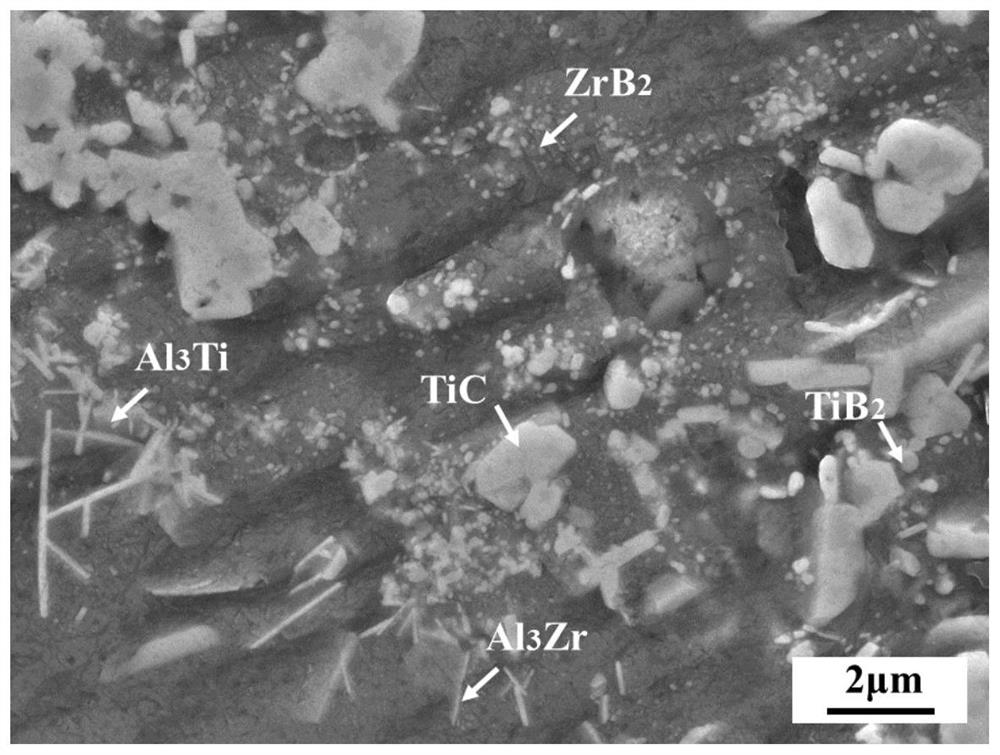

[0028] Based on the designed electromagnetic internal circulation compound preparation device, firstly, 500Kg of pure aluminum is placed in the crucible of the melting furnace and melted to 870°C, so that the top of the aluminum melt exceeds the upper outlet of the electromagnetic circulation device in the crucible and aluminum alloy is added to the top of the crucible Covering agent, and then start the electromagnetic circulation device. 15Kg Ti, 15Kg Zr, 16.1KgB dried at 200°C for 2 hours 2 o 3 , 5Kg C powder or shavings (respectively accounting for 3%, 3%, 3.2% and 1% of the total mass of the entire composite refinement strengthening agent) are added from the feeding port of the electromagnetic circulation device and circulated for 20 to 30 minutes, and then cooled to 720 ° C , cast to obtain Al-3Ti-3Zr-1B-1C composite refinement strengthener ingot. Adding 0.3% Al-3Ti-3Zr-1B-1C composite refinement strengthening agent in the pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com