A monitoring device, method and crusher for motor running state of seabed crusher

A technology for operating status and monitoring devices, which is applied to fluid pressure actuation devices, earthwork drilling, mechanical equipment, etc., can solve the problems of easy delay and neglect of abnormal conditions, monitoring of operating status, poor operating environment, etc., to reduce monitoring failures. risk, improve safety, and avoid dangerous accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

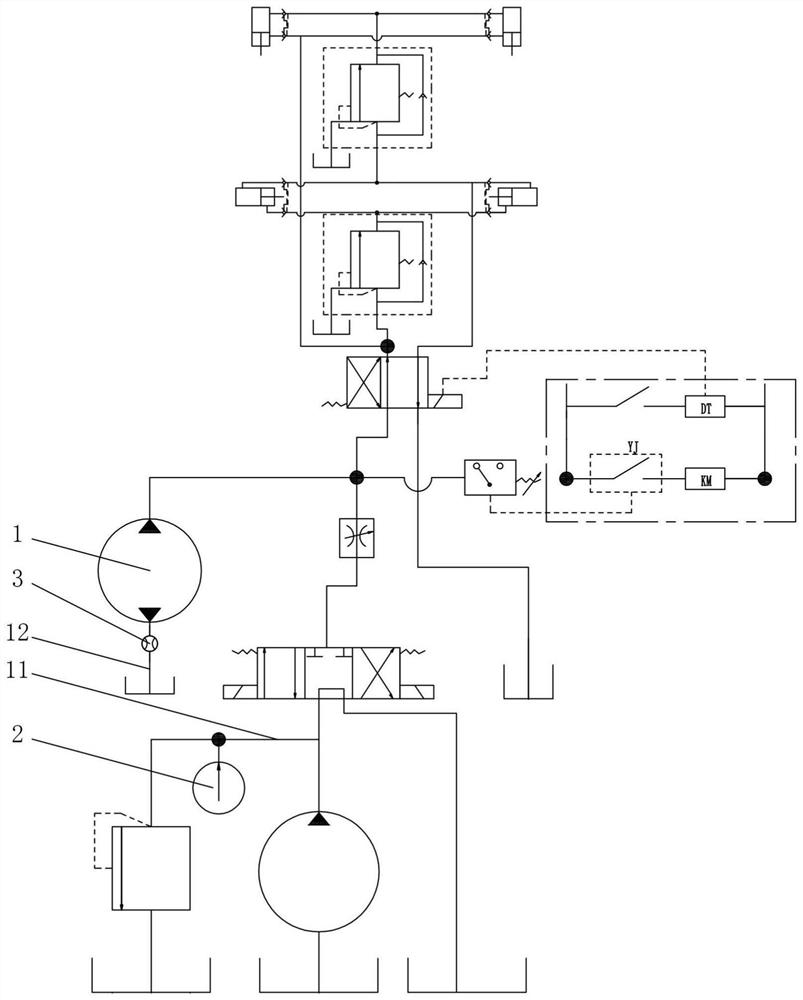

[0032] Such as figure 1 As shown, the monitoring device for the operating state of the seabed crusher motor in this embodiment includes a sensing device and a control system. The sensing device is installed on the motor 1 of the seabed crusher and will monitor the oil passage of the motor 1 obtained. The situation signal is sent to the control system; the control system includes a data processing module, a decision module and a display device, the data processing module compares the oil circuit situation signal of the motor 1 with the preset condition, and sends the comparison result to the decision module, which compares the The result is converted into the running state signal of the motor 1 and sent to the display device for display, and it is determined whether to alarm according to the comparison result. The monitoring device of this embodiment can warn the abnormal situation of the motor 1 at the first time, the information is timely, accurate and effective, and the abno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com