Superconducting cable and production method thereof

A technology for superconducting cables and superconducting layers, which is applied in superconducting devices, conducting materials, conducting materials, etc., can solve problems such as temperature rise and high resistance of superconducting cables, and achieve increased strength, grain refinement, and improved Effects of Corrosion Resistance and Oxidation Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

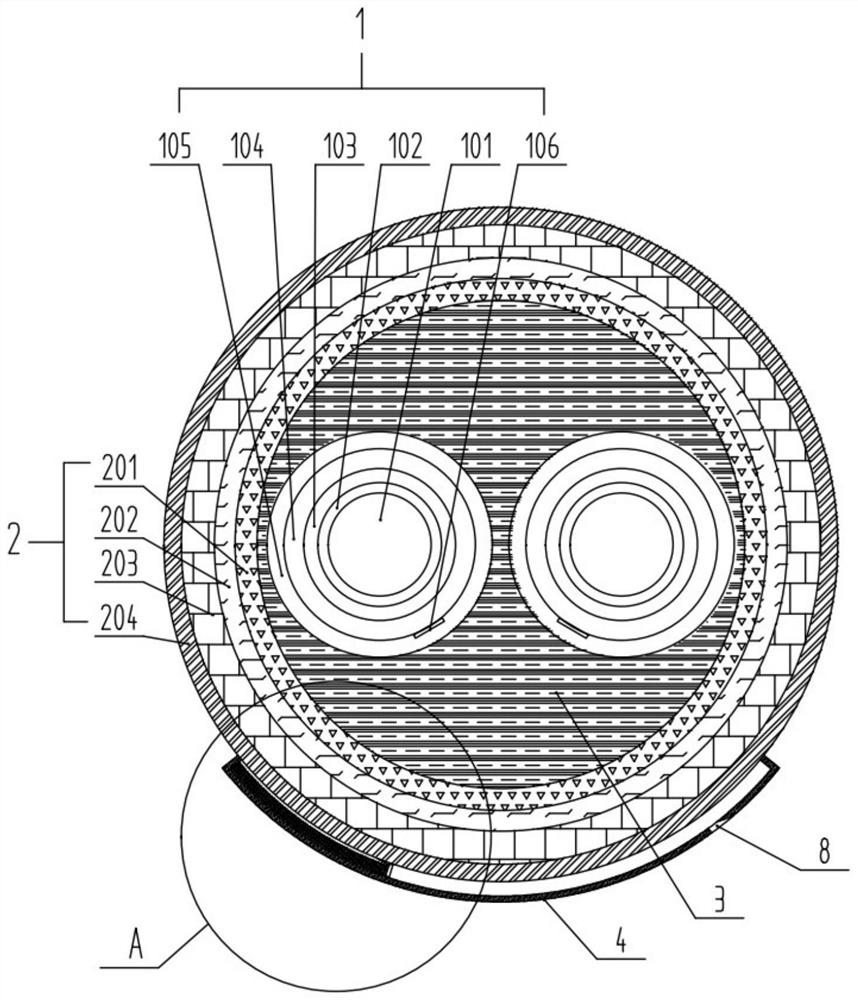

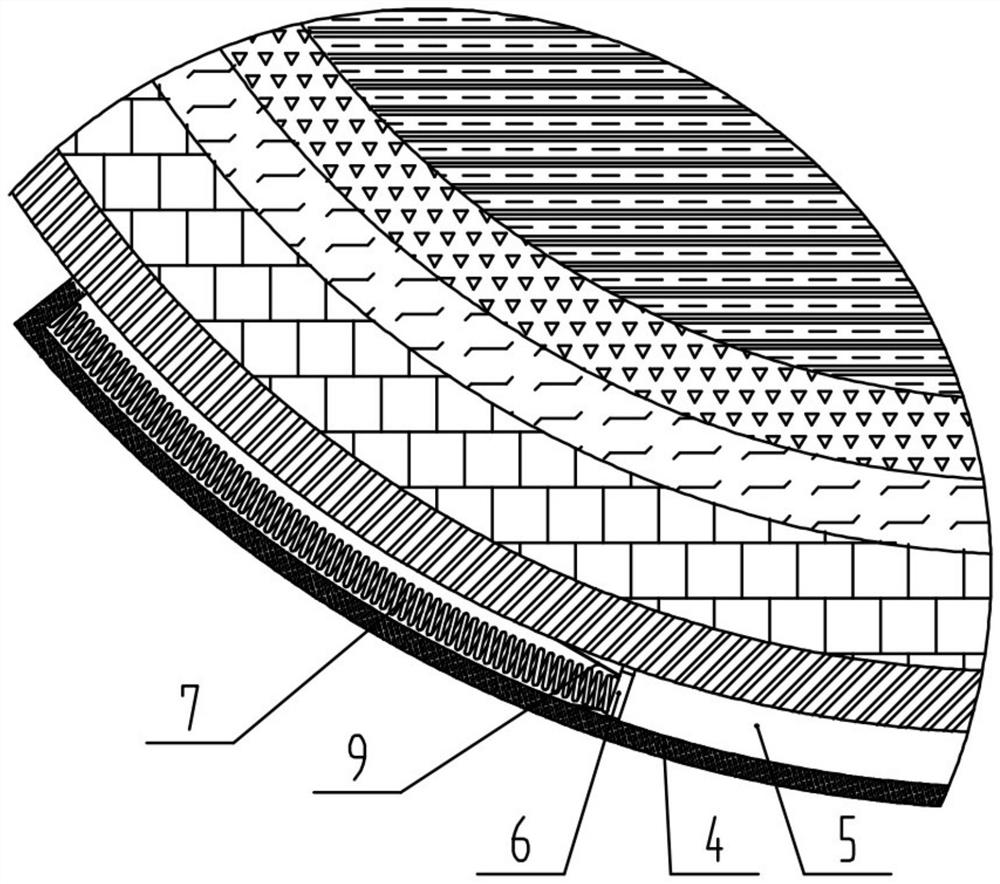

[0042] basically as attached figure 1 , attached figure 2 and attached image 3Shown: a superconductor cable, comprising three sets of cable cores 1 and a set of protective layers 2 . The cable core 1 includes an aluminum alloy superconductor layer 101 , an inner shielding layer 102 , an insulating layer 103 , an outer shielding layer 104 , and a copper tape shielding layer 105 sequentially from the inside to the outside. The composition of the aluminum alloy superconductor layer 101 includes yttrium barium copper oxide 1.50%, iron 0.62%, magnesium 0.03%, zinc 0.03%, copper 0.10%, boron 0.30%, chromium 0.12%, strontium 0.08%, manganese 0.77%, zirconium 0.04%, the balance is aluminum.

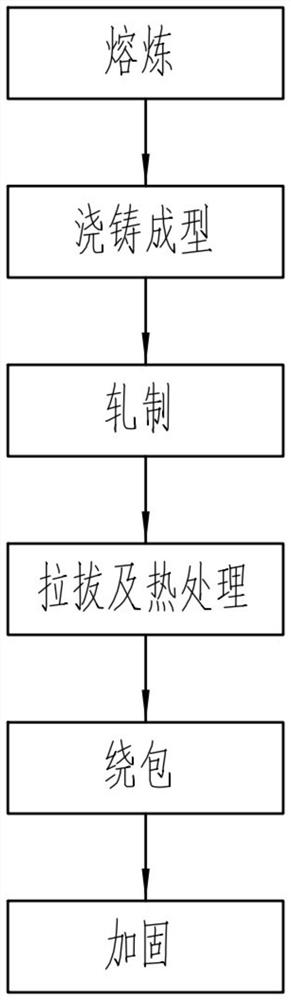

[0043] The specific production method of superconducting cable includes the following steps:

[0044] S1, smelting, preheating, grinding, and pulverizing the raw materials of the aluminum alloy superconductor layer 101 components according to the component ratio, and adding them to the heat...

Embodiment 2

[0055] The difference between this embodiment and the first embodiment is that, as shown in the appendix Figure 4 with attached Figure 5 As shown, the sounding part is a metal pick 10 , and one end of the metal pick 10 is fixedly connected to the inner wall of the monitoring cover 4 . A closed box 11 is pasted and fixed on one side of the adjacent monitoring cover 4 , and the side of the closed box 11 close to the protective layer 2 is open. One end of the airtight box 11 away from the monitoring cover 4 is provided with a through hole, and a gas check valve 12 is fixed with the inner thread of the through hole. A sealing plate 13 is slidably connected in the airtight box 11 along the circumferential direction of the superconducting cable. The peripheral outer wall of the sealing plate 13 abuts against the inner wall of the airtight box 11 . It communicates with the inside of the airtight box 11 . A connecting rod 15 is threadedly fixed between the sealing plate 13 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com