Guide-rail-type mass damper

A technology of mass damper and damper, which is applied in the field of damper, can solve the problems of large occupied space and achieve the effect of small occupied space, compact structure and flexible installation position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be further described below by means of specific examples, but the present invention is not limited to the scope of the following examples.

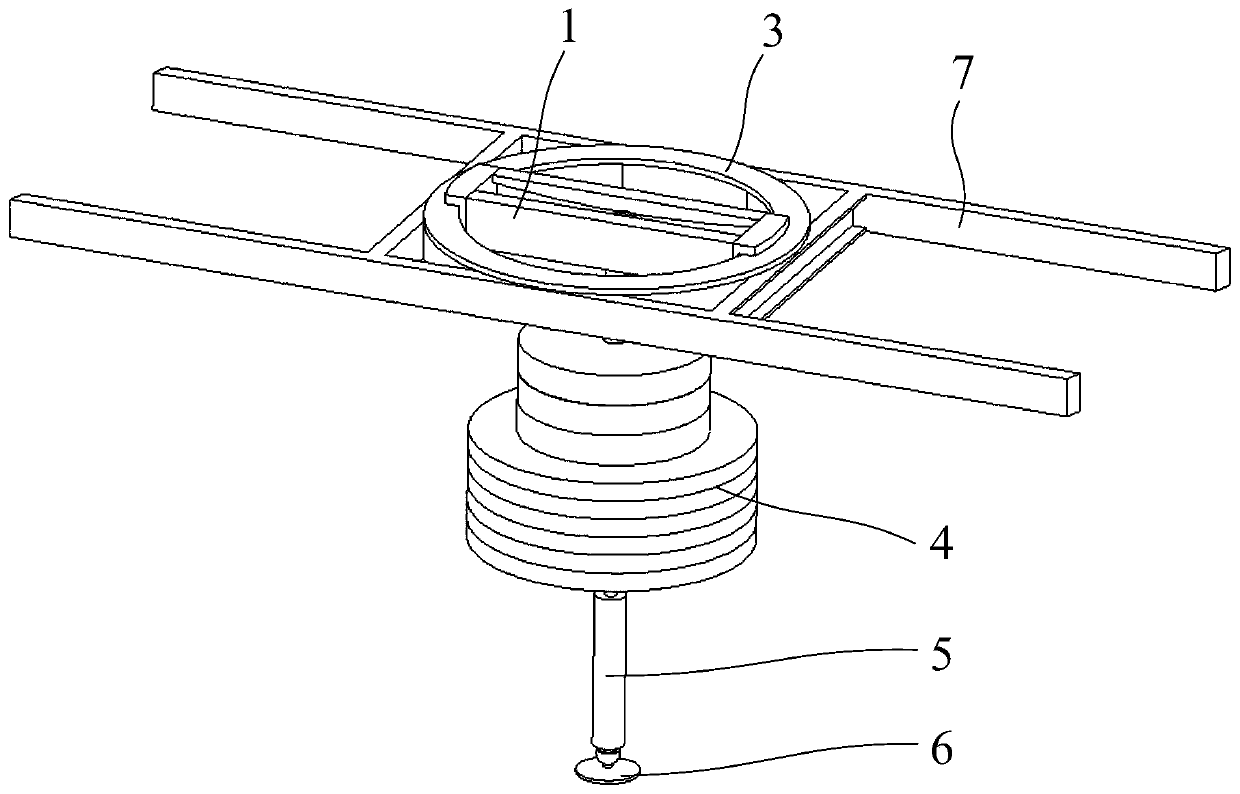

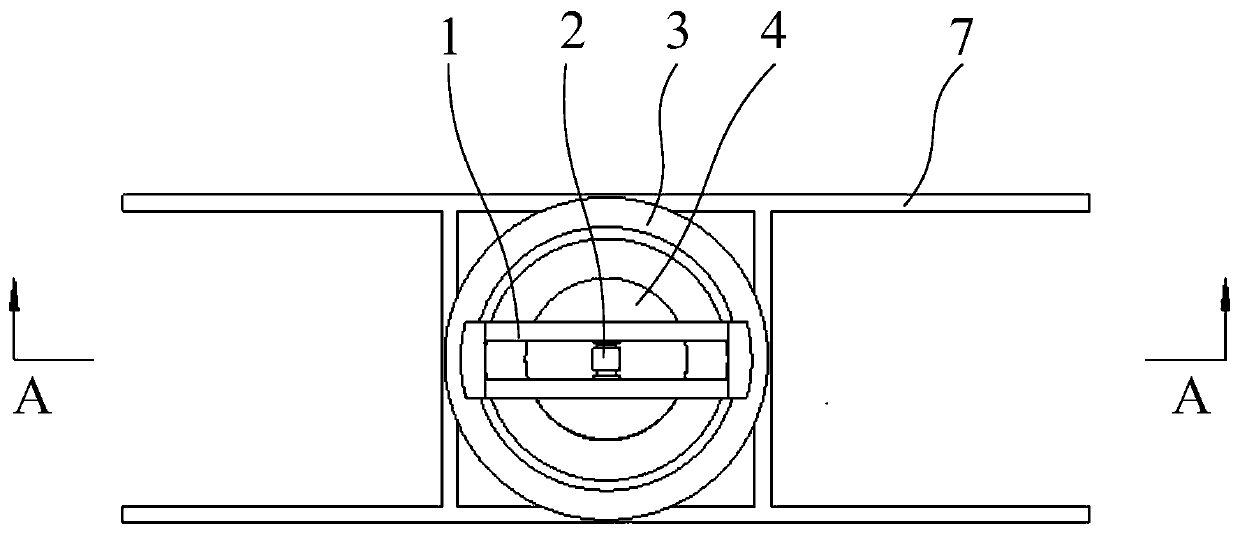

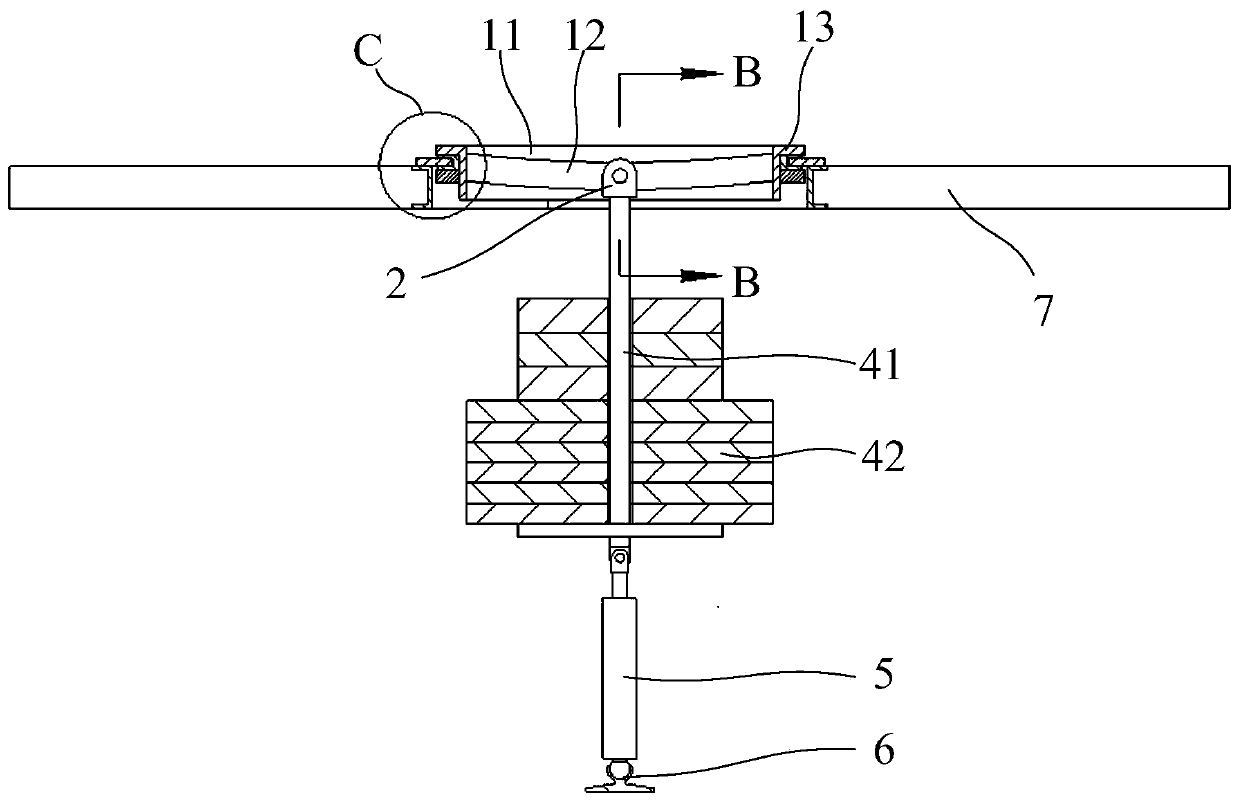

[0066] like Figure 1-7 As shown, a guide rail type mass damper of the present invention includes an arc guide rail assembly 1, a roller assembly 2, and a mass block assembly 4, and the center of the arc track of the arc guide rail assembly 1 is located above the arc track , the roller assembly 2 can freely roll on the circular arc track, and the mass block assembly 4 is connected below the roller assembly 2; wherein, the arc guide rail assembly 1 is installed in the cabin on the tower 8, or the arc guide rail The assembly 1 is installed in the tower 8 and can rotate in the tower 8 so that the direction of the circular arc track coincides with the vibration direction of the tower 8 .

[0067] When the rail-type mass damper of the present invention is installed in the nacelle on the tower 8, since the nac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com