Automatic liquid drainage system

A technology of automatic drainage and exhaust pipe, which is applied in the fields of pressure vessel manufacturing and automatic drainage system, can solve the problem that the valve body does not have action characteristics, and achieve the effect of avoiding danger.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

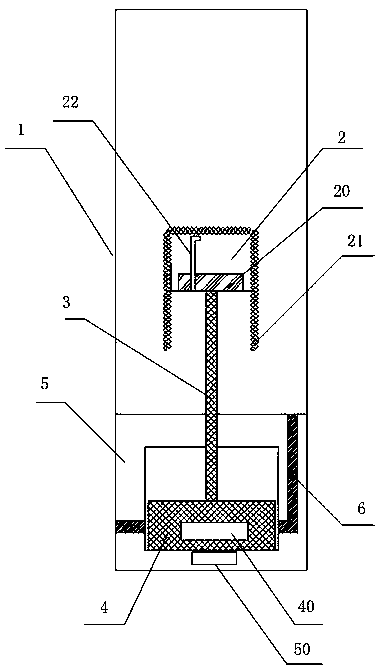

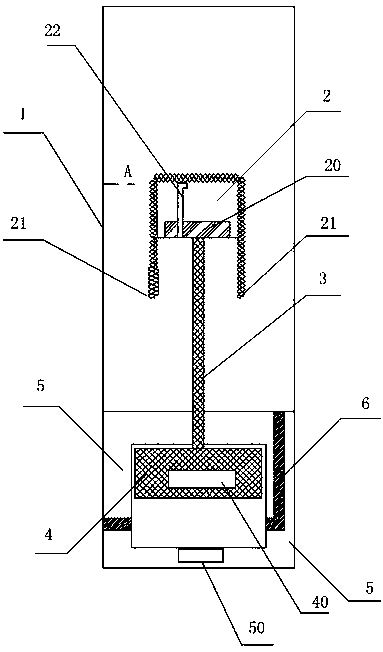

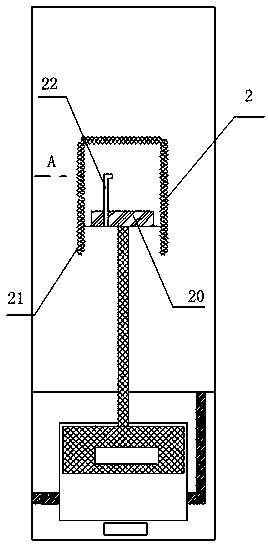

[0019] Such as figure 1 , figure 2 The automatic draining system of this embodiment includes: a tank body 1 and a ball float valve; The valve body 5 at the bottom; the tank body 1 is generally a closed cavity for storing various liquids.

[0020] The valve body 5 is provided with a drain channel 6 for connecting the tank body 1 with the outside world; the drain channel connects the tank body with the outside world, and when the liquid level is too high, the liquid is drained through the drain channel.

[0021] The valve body 5 is also sleeved with a slidable valve core 4, and the valve core 4 slides up and down to open or close the drain channel 6; as shown in the figure, the drain channel opens when the valve core slides up; When the spool slides, the discharge passage is cut off by the spool and the discharge is closed.

[0022] One end of the connecting rod 3 is connected with the floating ball 2 , and the other end is connected with the valve core 4 .

[0023] The bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com