Soil curing agent directly processing soil into surface layer of road

A soil stabilizer, a direct technology, applied in the direction of soil conditioning materials, chemical instruments and methods, organic fertilizers, etc., can solve the problems of high price and few practical applications, and achieve the effect of low cost, broad market prospect, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 2

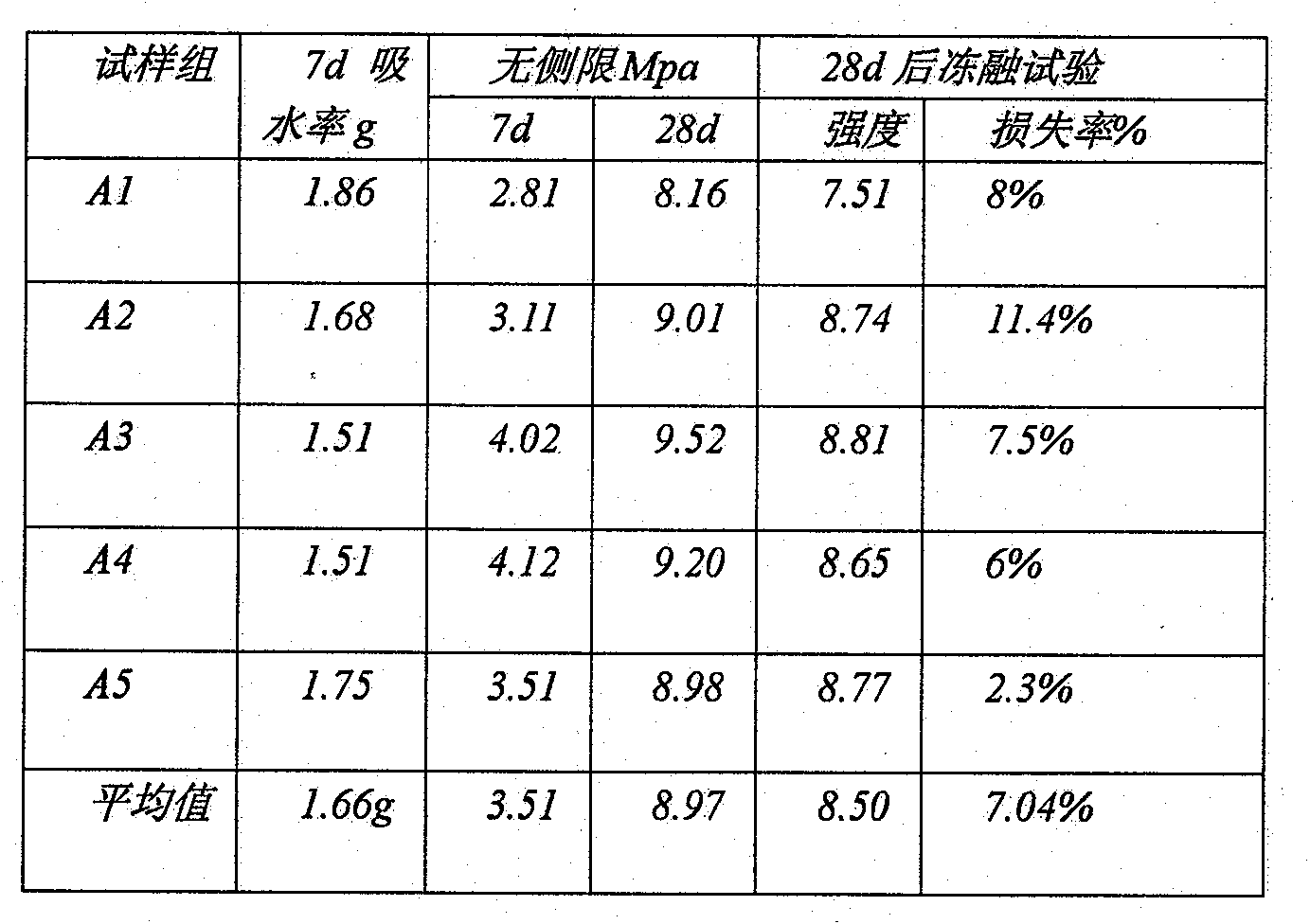

[0024] Implementation case 2, select a village-level pavement in the south-central region with a total area of about 2,000 square meters, and choose summer construction. Use this kind of soil curing agent at a rate of 1.2 / 10,000, a total of 100kg, 4% cement is evenly mixed and then compacted, and the surface is sprinkled with 2kg of stone powder per square, directly as the surface layer, completed in August 2008, and cored in October 2010 to resist compression The maximum strength is 8.5Mpa. It has been used so far without any cracks on the surface. The traffic is normal. It does not slip when it rains, and it does not ash when it is sunny.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com